Ventilation through tunnel door | Pad cooling | GW

We are happy to help you with making a calculation

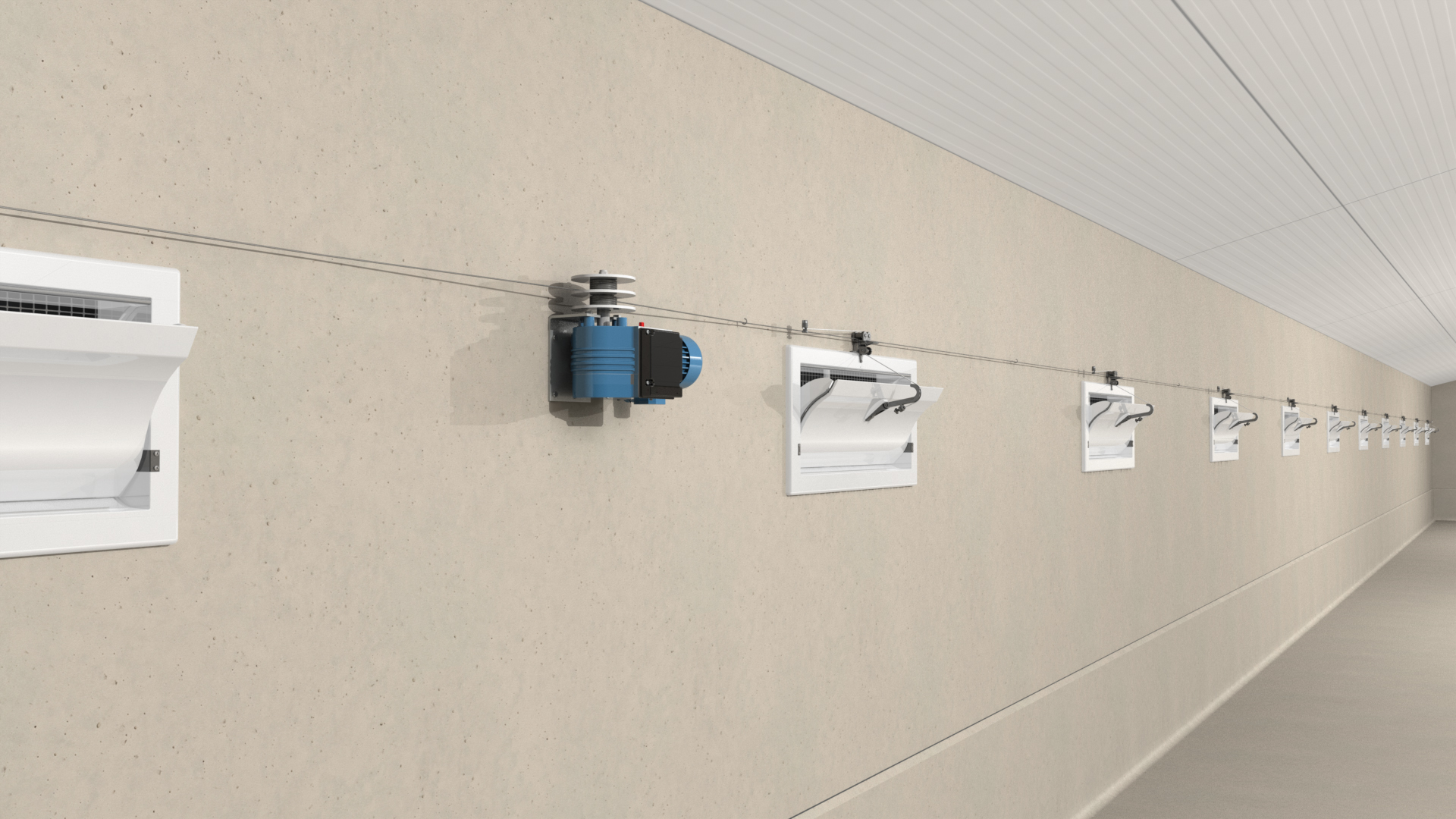

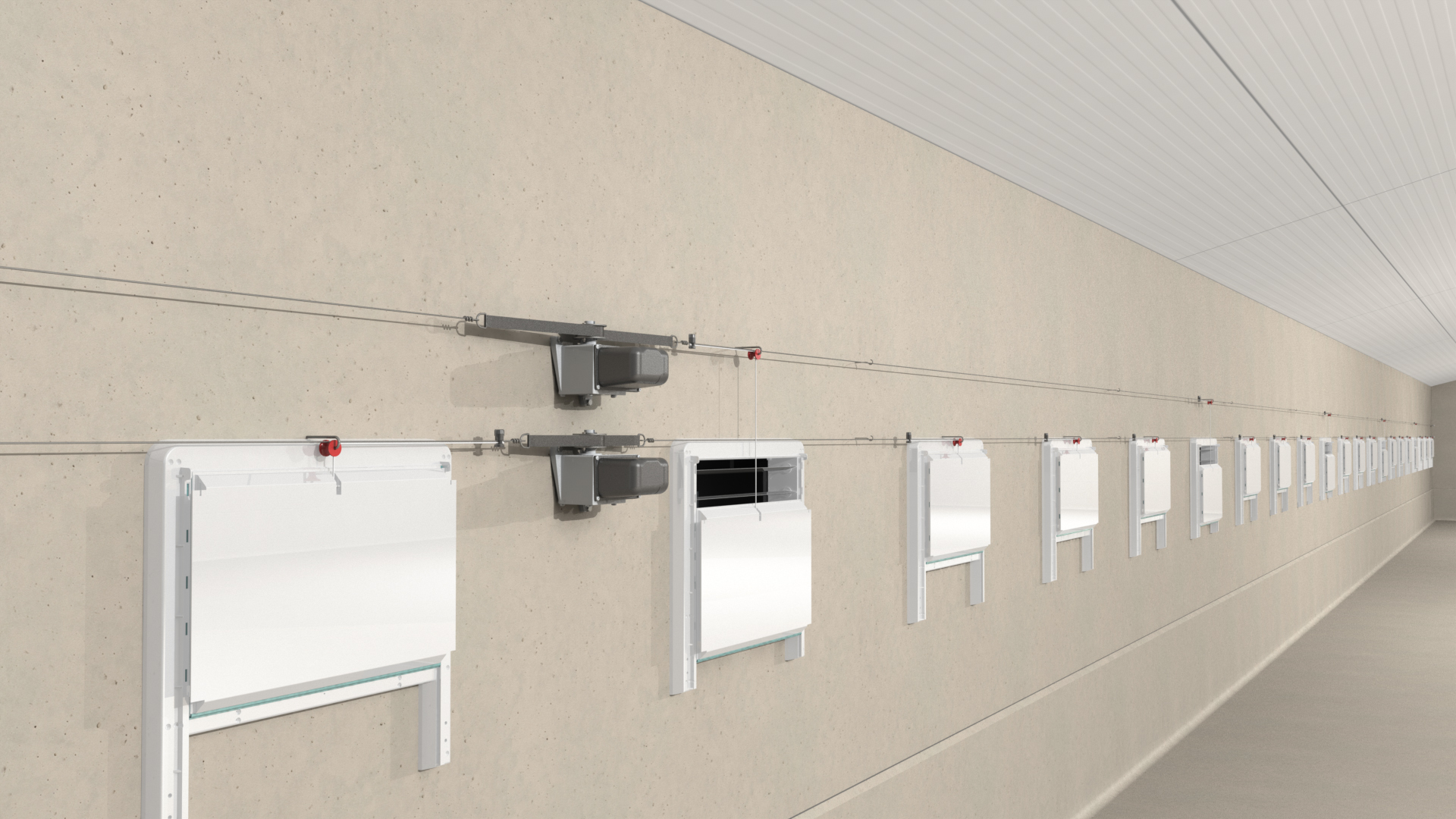

Get in contact with usTunnel doors are mainly used in areas with high temperatures. Pad cooling is also used in extreme climates. A combination of inlet valves and tunnel doors for extremely low and high temperature areas. By opening the tunnel doors with a rack drive, the system ensures high air velocity and a chilling effect for the livestock.

- For the best climate and animal welfare.

- Very accurate with KL300 MultiWinch.

- Ideal operation in combination with rack system.

- Precise tunnel door opening and closing.

- Low-maintenance and low noise.

- Cost-effective solution.

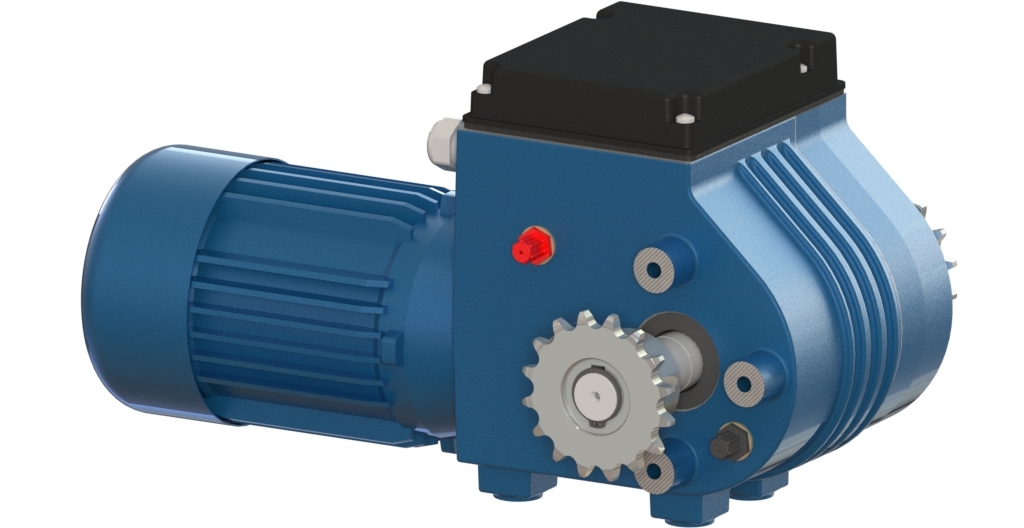

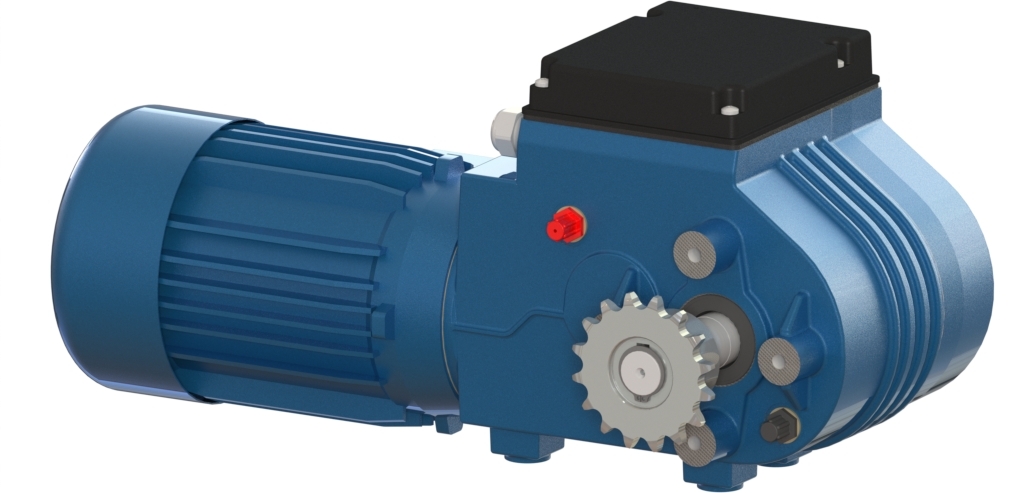

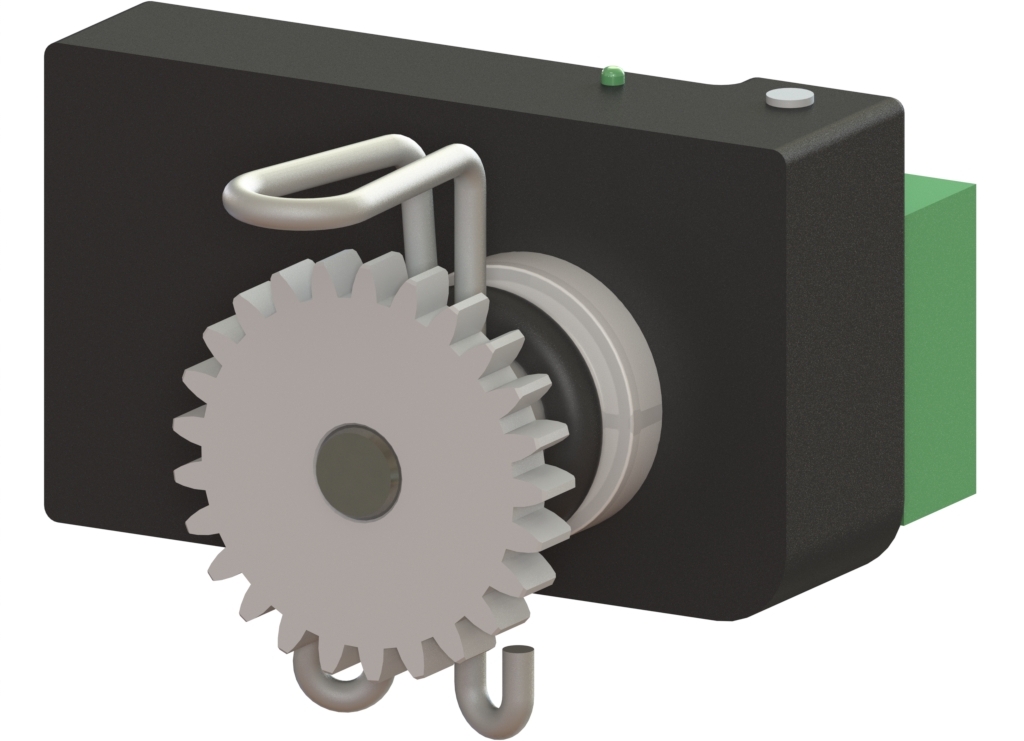

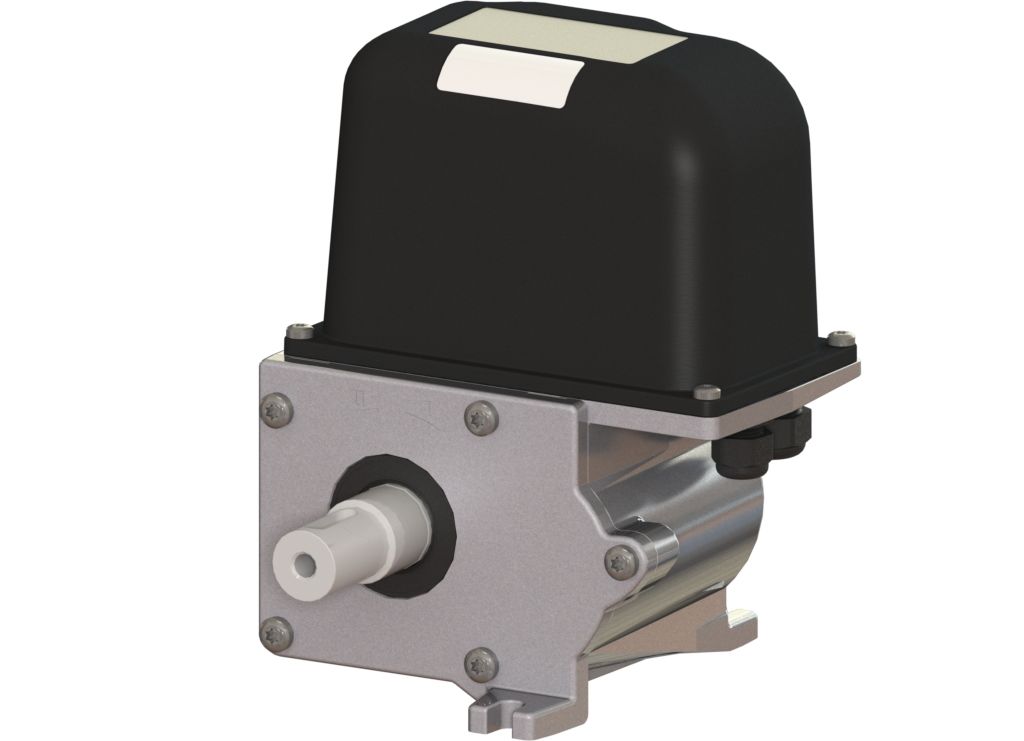

GW motor gearbox

| Article | Article name | T [Nm] | n (400V 50Hz) [rpm] | n (480V 60Hz) [rpm] | P [kW] | I [A] | Shaft/Chain | L [mm] | m [kg] |

| P.GW10.3.230.13.KW | GW10 1.3 1ph 230V with CW+CH 10B z16 | 100 / - | 1,3 / - | 191 | 124 | 0,09 / - | 1,1 / - | - | 21 |

2 P.GW10.3.230.13.KW 11 GW10 1.3 1ph 230V with CW+CH 10B z16 12 13 P.GW10.400.26.KW.jpg 14 15 CAT_P.GW10.400.26.KW_2D.gif 17 16 10 | |||||||||

| P.GW10.3.230.26.KW | GW10 2.6 1ph 230V with CW+CH 10B z16 | 100 / - | 2,6 / - | 168 | 124 | 0,09 / - | 0,9 / - | - | 21 |

2 P.GW10.3.230.26.KW 11 GW10 2.6 1ph 230V with CW+CH 10B z16 12 13 P.GW10.400.26.KW.jpg 14 15 CAT_P.GW10.400.26.KW_2D.gif 17 16 10 | |||||||||

| P.GW10.3.400.13.KW | GW10 1.3 3ph 400V with CW+CH 10B z16 | 100 / 80 | 1,3 / 1,6 | 191 | 124 | 0,09 / 0,11 | 0,5 / 0,5 | 0,9 / 0,9 | 21 |

2 P.GW10.3.400.13.KW 11 GW10 1.3 3ph 400V with CW+CH 10B z16 12 13 P.GW10.400.26.KW.jpg 14 15 CAT_P.GW10.400.26.KW_2D.gif 17 16 10 | |||||||||

| P.GW10.3.400.26.KW | GW10 2.6 3ph 400V with CW+CH 10B z16 | 100 / 80 | 2,6 / 3,1 | 168 | 124 | 0,09 / 0,11 | 0,4 / 0,4 | 0,7 / 0,7 | 21 |

2 P.GW10.3.400.26.KW 11 GW10 2.6 3ph 400V with CW+CH 10B z16 12 13 P.GW10.400.26.KW.jpg 14 15 CAT_P.GW10.400.26.KW_2D.gif 17 16 10 | |||||||||

| P.GW30.2.230.13.KW | GW30 1.3 1ph 230V with CW+CH 10B z16 | 300 / - | 1,3 / - | 220 | 145 | 0,12 / - | 1,3 / - | - | 19 |

2 P.GW30.2.230.13.KW 11 GW30 1.3 1ph 230V with CW+CH 10B z16 12 13 P.GW30.400.26.KW.jpg 14 15 CAT_P.GW30.400.26.KW_2D.gif 17 16 10 | |||||||||

| P.GW30.2.230.26.KW | GW30 2.6 1ph 230V with CW+CH 10B z16 | 300 / - | 2,6 / - | 220 | 145 | 0,12 / - | 1,3 / - | - | 21 |

2 P.GW30.2.230.26.KW 11 GW30 2.6 1ph 230V with CW+CH 10B z16 12 13 P.GW30.400.26.KW.jpg 14 15 CAT_P.GW30.400.26.KW_2D.gif 17 16 10 | |||||||||

| P.GW30.400.13.KW | GW30 1.3 3ph 400V with CW+CH 10B z16 | 300 / 240 | 1,3 / 1,6 | 191 | 145 | 0,18 / 0,22 | 0,7 / 0,7 | 1,2 / 1,2 | 22 |

2 P.GW30.400.13.KW 11 GW30 1.3 3ph 400V with CW+CH 10B z16 12 13 P.GW30.400.26.KW.jpg 14 15 CAT_P.GW30.400.26.KW_2D.gif 17 16 10 | |||||||||

| P.GW30.400.26.KW | GW30 2.6 3ph 400V with CW+CH 10B z16 | 300 / 240 | 2,6 / 3,1 | 220 | 145 | 0,25 / 0,30 | 0,8 / 0,8 | 1,4 / 1,4 | 24 |

2 P.GW30.400.26.KW 11 GW30 2.6 3ph 400V with CW+CH 10B z16 12 13 P.GW30.400.26.KW.jpg 14 15 CAT_P.GW30.400.26.KW_2D.gif 17 16 10 | |||||||||

| P.GW40.2.230.13.KW | GW40 1.3 1ph 230V with CW+CH 10B z16 | 400 / - | 1,3 / - | 220 | 159 | 0,25 / - | 3,1 / - | - | 26 |

2 P.GW40.2.230.13.KW 11 GW40 1.3 1ph 230V with CW+CH 10B z16 12 13 P.GW80.400.26.KW.jpg 14 15 CAT_P.GW80.400.26.KW_2D.gif 17 16 10 | |||||||||

| P.GW40.2.230.26.KW | GW40 2.6 1ph 230V with CW+CH 10B z16 | 400 / - | 2,6 / - | 220 | 137 | 0,25 / - | 3,2 / - | - | 29 |

2 P.GW40.2.230.26.KW 11 GW40 2.6 1ph 230V with CW+CH 10B z16 12 13 P.GW80.400.26.KW.jpg 14 15 CAT_P.GW80.400.26.KW_2D.gif 17 16 10 | |||||||||

| P.GW40.400.13.KW | GW40 1.3 3ph 400V with CW+CH 10B z16 | 400 / 320 | 1,3 / 1,6 | 220 | 159 | 0,25 / 0,30 | 0,8 / 0,8 | 1,4 / 1,4 | 27 |

2 P.GW40.400.13.KW 11 GW40 1.3 3ph 400V with CW+CH 10B z16 12 13 P.GW80.400.26.KW.jpg 14 15 CAT_P.GW80.400.26.KW_2D.gif 17 16 10 | |||||||||

| P.GW40.400.26.KW | GW40 2.6 3ph 400V with CW+CH 10B z16 | 400 / 320 | 2,6 / 3,1 | 220 | 159 | 0,37 / 0,44 | 1,0 / 1,0 | 1,7 / 1,7 | 29 |

2 P.GW40.400.26.KW 11 GW40 2.6 3ph 400V with CW+CH 10B z16 12 13 P.GW80.400.26.KW.jpg 14 15 CAT_P.GW80.400.26.KW_2D.gif 17 16 10 |

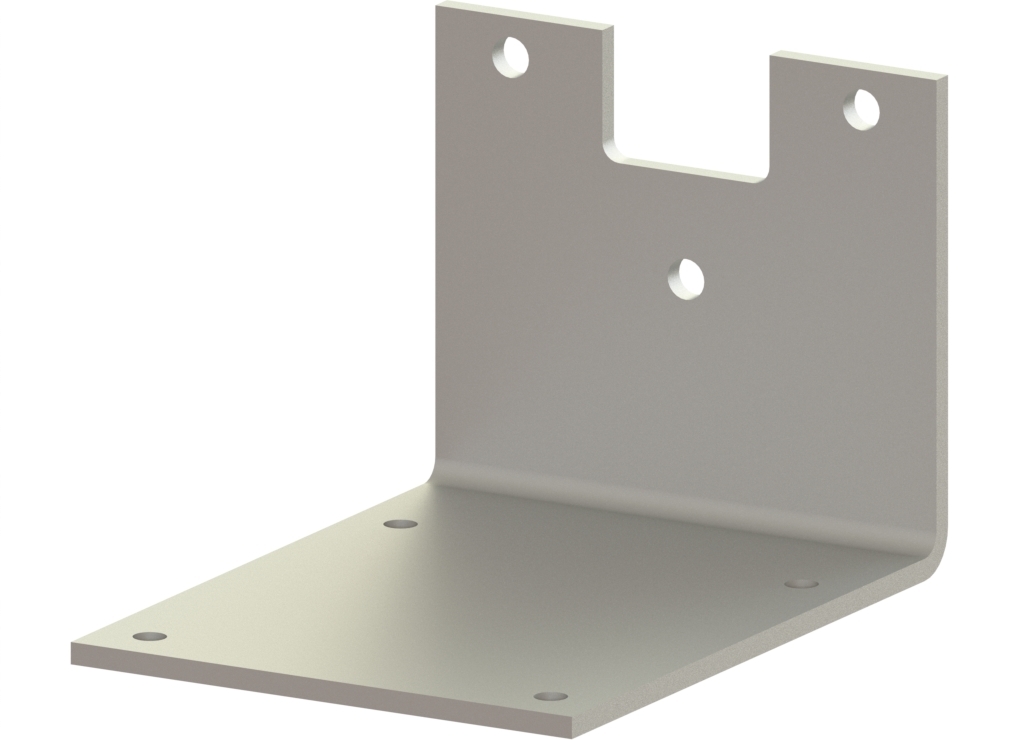

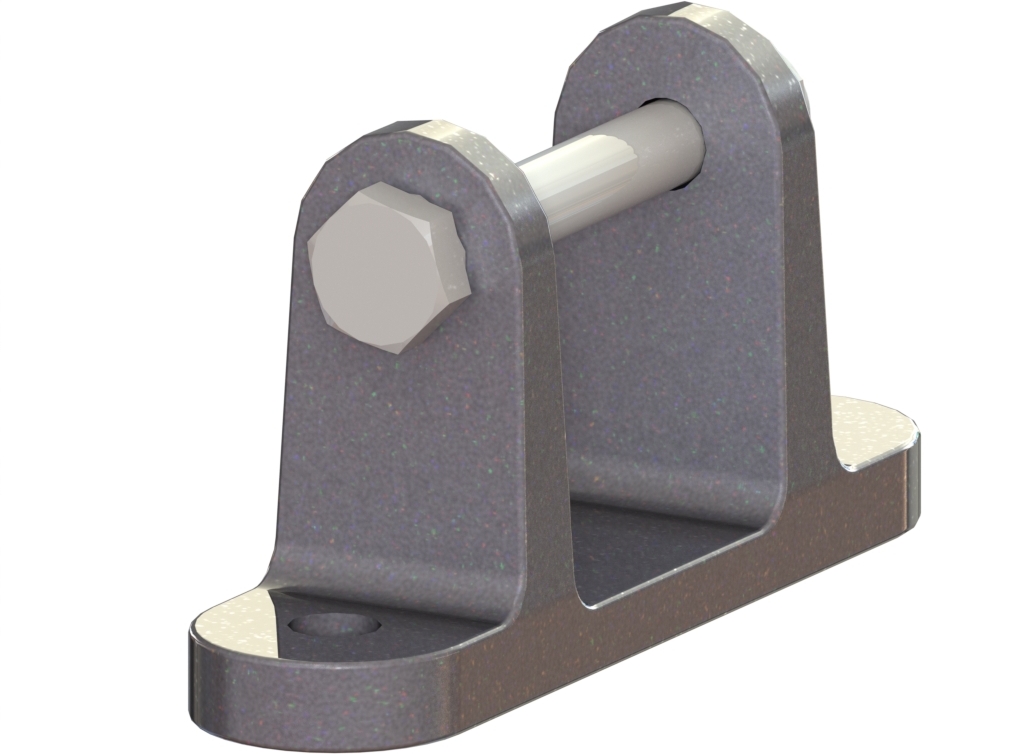

Mounting plate GW

| Article | Description | A [mm] | H [mm] | m [kg] |

| P.MP.GW.H.A100 | Mounting plate GW right angle A100 H111 | 100 | 111 | 2,0 |

| P.MP.GW.H.A122 | Mounting plate GW right angle A122 H133 | 122 | 133 | 2,2 |

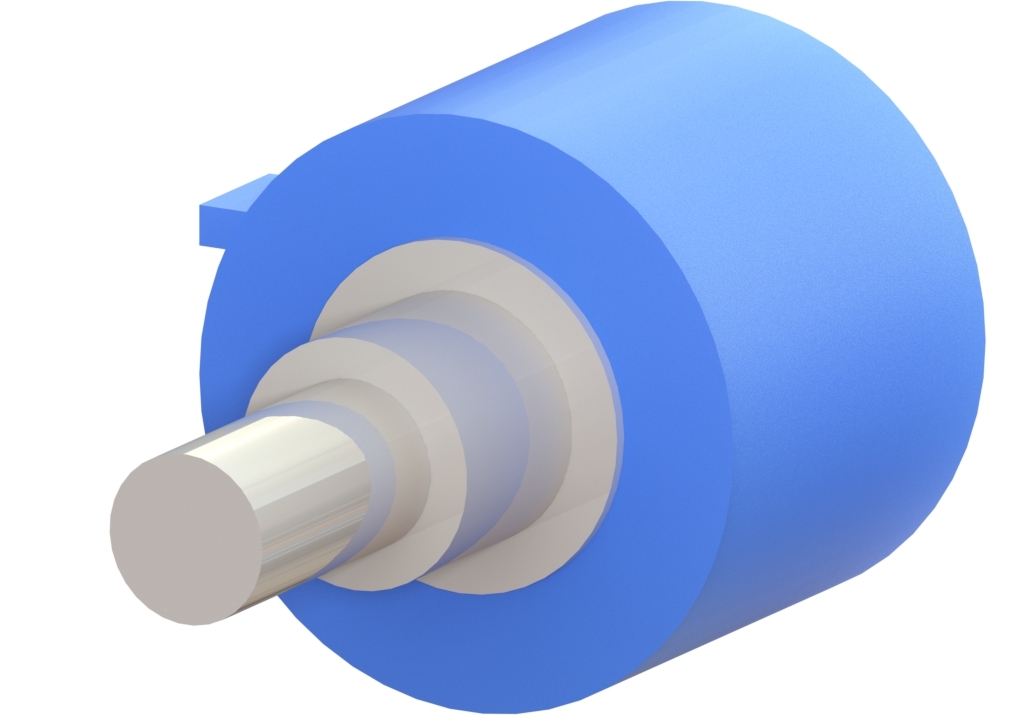

Tube bolt sprocket

| Article | Description | Chain | Shaft | Tmax [Nm] | Db [mm] | D [mm] | L [mm] | m [kg] |

| P.BBKWL10B.Z16.D100 | Tube bolt sprocket 10B z16 - 1" | 10B z16 | D100 | 420 | 34 | 96 | 150 | 0,8 |

2 P.BBKWL10B.Z16.D100 11 Tube bolt sprocket 10B z16 - 1" 12 13 P.BBKWL10B.Z16.D100.jpg 15 16 CAT_P.BBKWL10B.Z16.D100_2D.gif 17 10 |

Weld sprocket

| Article | Description | Chain | Shaft | Tmax [Nm] | Db [mm] | D [mm] | L [mm] | m [kg] |

| P.LKWL10B.Z16.D100 | Weld sprocket 10B z16 - 1" and 2" | 10B z16 | D100 | 420 | 34 | 96 | 30 | 0,5 |

2 P.LKWL10B.Z16.D100 11 Weld sprocket 10B z16 - 1" and 2" 12 13 P.LKWL10B.Z16.D100.jpg 15 16 CAT_P.LKWL10B.Z16.D100_2D.gif 17 10 |

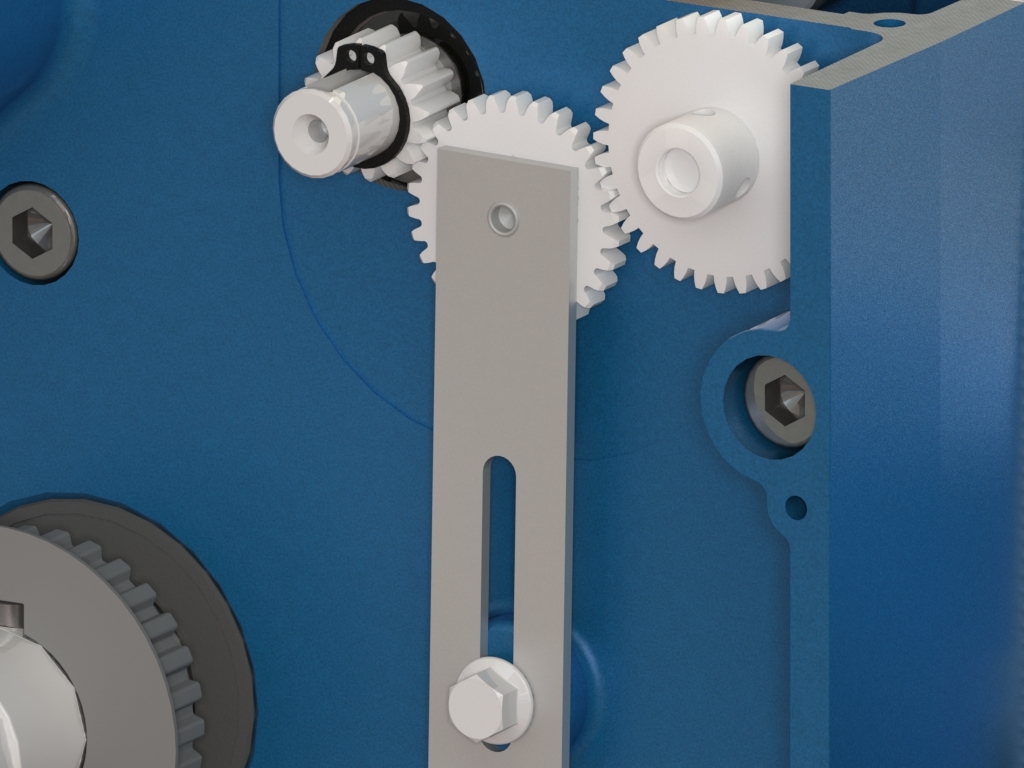

Rack box

| Article | Description | T [Nm] | s [mm/rev] | Usage | m [kg] |

| P.THG30.UNIT.U | THG30 Universal | 10,4 | 138,23 | Intens | 0,43 |

Rack THG30

| Article | Description | F [N] | L [mm] | B [mm] | D [mm] | m [kg] |

| P.THG30.3.L797 | THG30 rack 3 mm L=797 mm | 450 | 797 | 25 | 3 | 1,2 |

2 P.THG30.3.L797 11 THG30 rack 3 mm L=797 mm 12 13 RAW_P.THG30.0.L0000.jpg 14 10 CAT_P.THG30.3.L0000_2D.gif | ||||||

| P.THG30.3.L998 | THG30 rack 3 mm L=998 mm | 450 | 998 | 25 | 3 | 1,5 |

2 P.THG30.3.L998 11 THG30 rack 3 mm L=998 mm 12 13 RAW_P.THG30.0.L0000.jpg 14 10 CAT_P.THG30.3.L0000_2D.gif | ||||||

| P.THG30.3.L1099 | THG30 rack 3 mm L=1099 mm | 450 | 1099 | 25 | 3 | 1,7 |

2 P.THG30.3.L1099 11 THG30 rack 3 mm L=1099 mm 12 13 RAW_P.THG30.0.L0000.jpg 14 10 CAT_P.THG30.3.L0000_2D.gif | ||||||

| P.THG30.3.L1250 | THG30 rack 3 mm L=1250 mm | 450 | 1250 | 25 | 3 | 1,9 |

2 P.THG30.3.L1250 11 THG30 rack 3 mm L=1250 mm 12 13 RAW_P.THG30.0.L0000.jpg 14 10 CAT_P.THG30.3.L0000_2D.gif | ||||||

| P.THG30.3.L1300 | THG30 rack 3 mm L=1300 mm | 450 | 1300 | 25 | 3 | 2,0 |

2 P.THG30.3.L1300 11 THG30 rack 3 mm L=1300 mm 12 13 RAW_P.THG30.0.L0000.jpg 14 10 CAT_P.THG30.3.L0000_2D.gif | ||||||

| P.THG30.3.L1400 | THG30 rack 3 mm L=1400 mm | 450 | 1400 | 25 | 3 | 2,2 |

2 P.THG30.3.L1400 11 THG30 rack 3 mm L=1400 mm 12 13 RAW_P.THG30.0.L0000.jpg 14 10 CAT_P.THG30.3.L0000_2D.gif | ||||||

| P.THG30.3.L1451 | THG30 rack 3 mm L=1451 mm | 450 | 1451 | 25 | 3 | 2,2 |

2 P.THG30.3.L1451 11 THG30 rack 3 mm L=1451 mm 12 13 RAW_P.THG30.0.L0000.jpg 14 10 CAT_P.THG30.3.L0000_2D.gif | ||||||

| P.THG30.3.L1500 | THG30 rack 3 mm L=1500 mm | 450 | 1500 | 25 | 3 | 2,2 |

2 P.THG30.3.L1500 11 THG30 rack 3 mm L=1500 mm 12 13 RAW_P.THG30.0.L0000.jpg 14 10 CAT_P.THG30.3.L0000_2D.gif | ||||||

| P.THG30.3.L1652 | THG30 rack 3 mm L=1652 mm | 450 | 1652 | 25 | 3 | 2,5 |

2 P.THG30.3.L1652 11 THG30 rack 3 mm L=1652 mm 12 13 RAW_P.THG30.0.L0000.jpg 14 10 CAT_P.THG30.3.L0000_2D.gif | ||||||

| P.THG30.3.L1953 | THG30 rack 3 mm L=1953 mm | 450 | 1953 | 25 | 3 | 3,0 |

2 P.THG30.3.L1953 11 THG30 rack 3 mm L=1953 mm 12 13 RAW_P.THG30.0.L0000.jpg 14 10 CAT_P.THG30.3.L0000_2D.gif |

Window bracket set

| Article | Article name | m [kg] |

| P.THG30.RB | THG30 aluminium window bracket | 0,06 |

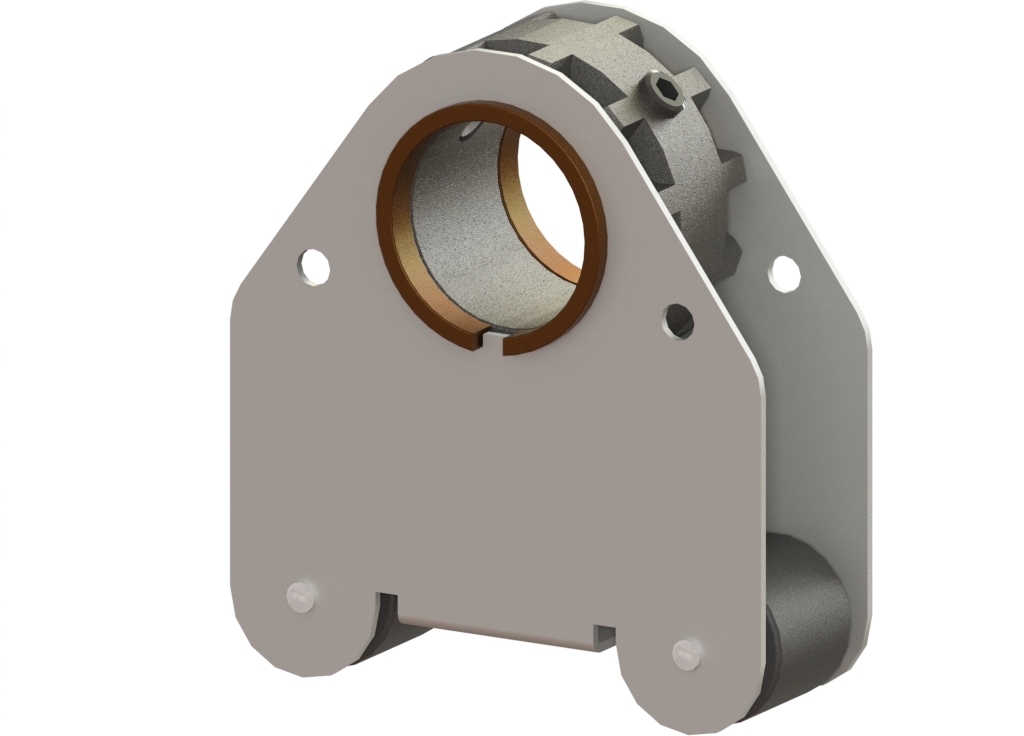

Slide bearing plate

| Article | Description | A [mm] | H [mm] | L [mm] | m [kg] |

| P.GL100.H.L180 | Slide bearing plate 1" H A122 L180 mm | 122 | 155 | 180 | 0,2 |

Encoder I-DE

| Article | Article name | n [rpm] | m [kg] |

| P.IDE.024.01 | I-DE 24V AC/DC digital/analogue Enc. built-in | 1,2 - 8,0 | 0,06 |

Potentiometer

| Article | Description | Ohm [ohm] | m [kg] |

| P.PM.500 | Potentiometer 500 ohm built-in | 500 | 0,037 |

| P.PM.1000 | Potentiometer 1000 ohm built-in | 1000 | 0,037 |

| P.PM.5000 | Potentiometer 5000 ohm built-in | 5000 | 0,037 |

| P.PM.10000 | Potentiometer 10 000 ohm built-in | 10000 | 0,037 |

Potentiometer gear set

| Article | Description | i [-] | m [kg] |

| P.PM.TWS.6,00 | Gear set 30.32.48.30 | 6,00 | 0,10 |

| P.PM.TWS.6,38 | Gear set 30.34.48.30 | 6,38 | 0,10 |

| P.PM.TWS.6,58 | Gear set 70.32.30.48 | 6,58 | 0,10 |

| P.PM.TWS.7,20 | Gear set 68.34.30.48 | 7,20 | 0,13 |

| P.PM.TWS.8,16 | Gear set 30.17.30.48 | 8,16 | 0,10 |

| P.PM.TWS.8,64 | Gear set 30.18.30.48 | 8,64 | 0,10 |

| P.PM.TWS.9,60 | Gear set 30.20.30.48 | 9,60 | 0,10 |

| P.PM.TWS.10,08 | Gear set 30.21.30.48 | 10,0 | 0,10 |

| P.PM.TWS.11,04 | Gear set 30.23.30.48 | 11,0 | 0,10 |

| P.PM.TWS.11,52 | Gear set 30.24.30.48 | 11,5 | 0,10 |

| P.PM.TWS.12,48 | Gear set 30.26.30.48 | 12,4 | 0,10 |

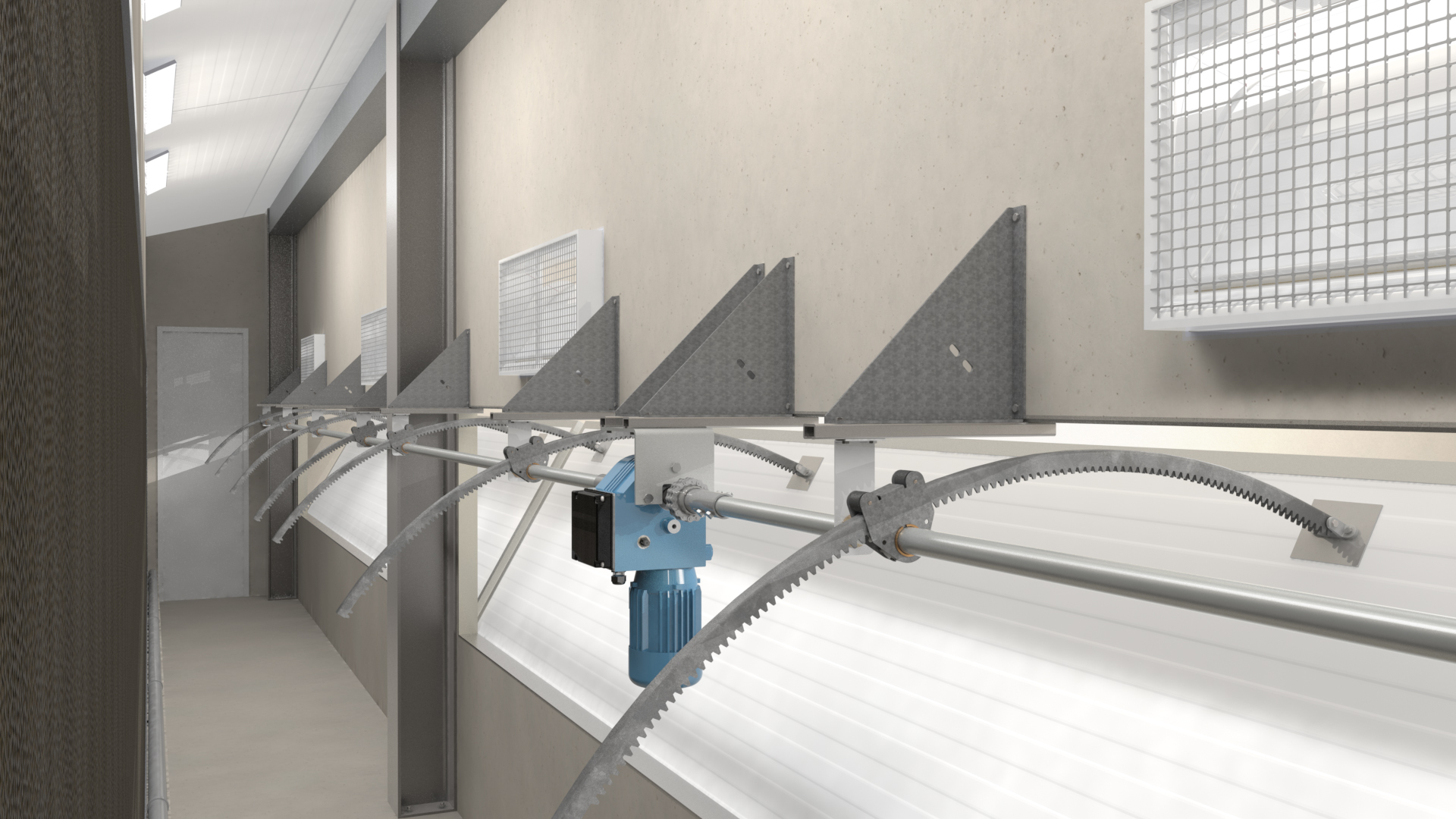

Drive systems for ventilation

A healthy building environment determines the livestock' productivity, growth, food consumption, stress levels and infection risks. Fresh air is vital important, where it enters in an optimal direction, at the right height and speed. For this we offer the highly innovative KL300 MultiWinch, which is specifically designed for this form of ventilation. The well-known GW series combined with winch drums or TGA rack and pinion is the solution for opening and closing tunnel doors.

Ventilation through tunnel door | Pad cooling | KL300

We are happy to help you with making a calculation

Get in contact with usTunnel doors are mainly used in areas with high temperatures. Pad cooling is also used in extreme climates. A combination of inlet valves and tunnel doors for extremely low and high temperature areas. By opening the tunnel doors with a rack drive, the system ensures high air velocity and a chilling effect for the livestock.

- For the best climate and animal welfare.

- Very accurate with KL300 MultiWinch.

- Ideal operation in combination with rack system.

- Precise tunnel door opening and closing.

- Low-maintenance and low noise.

- Cost-effective solution.

KL300 MultiWinch

| Article | Description | T [Nm] | n [rpm] | P [VA] | I [A] | s [rev] | m [kg] |

| P.KL300.1.024.08.L | KL300 0.8 24VDC for winch drum / sprocket | 90 | 0,8 (0,4) | 72 (48) | 3,0 (2,0) | 0,25 - 100 | 6,2 |

2 P.KL300.1.024.08.L 11 KL300 0.8 24VDC for winch drum / sprocket 12 13 P.KL300.1.024.08.L.jpg 14 15 CAT_P.KL300.1.024.08.L_2D.gif 10 |

Sprockets

| Article | Description | Chain | Tmax [Nm] | D1 [mm] | D2 [mm] | L [mm] | m [kg] |

| P.KWL10B.Z16.D25 | Sleeve sprocket 10B z16 | 10B z16 | 420 | 25 | 96 | 40 | 0,6 |

2 P.KWL10B.Z16.D25 11 Sleeve sprocket 10B z16 12 13 P.KWL10B.Z16.D00.jpg 14 15 CAT_P.KWL10B.Z16.D00_2D.gif 10 |

Tube bolt sprocket

| Article | Description | Chain | Shaft | Tmax [Nm] | Db [mm] | D [mm] | L [mm] | m [kg] |

| P.BBKWL10B.Z16.D100 | Tube bolt sprocket 10B z16 - 1" | 10B z16 | D100 | 420 | 34 | 96 | 150 | 0,8 |

2 P.BBKWL10B.Z16.D100 11 Tube bolt sprocket 10B z16 - 1" 12 13 P.BBKWL10B.Z16.D100.jpg 15 16 CAT_P.BBKWL10B.Z16.D100_2D.gif 17 10 |

Weld sprocket

| Article | Description | Chain | Shaft | Tmax [Nm] | Db [mm] | D [mm] | L [mm] | m [kg] |

| P.LKWL10B.Z16.D100 | Weld sprocket 10B z16 - 1" and 2" | 10B z16 | D100 | 420 | 34 | 96 | 30 | 0,5 |

2 P.LKWL10B.Z16.D100 11 Weld sprocket 10B z16 - 1" and 2" 12 13 P.LKWL10B.Z16.D100.jpg 15 16 CAT_P.LKWL10B.Z16.D100_2D.gif 17 10 |

Rack box

| Article | Description | T [Nm] | s [mm/rev] | Usage | m [kg] |

| P.THG30.UNIT.U | THG30 Universal | 10,4 | 138,23 | Intens | 0,43 |

Rack THG30

| Article | Description | F [N] | L [mm] | B [mm] | D [mm] | m [kg] |

| P.THG30.3.L797 | THG30 rack 3 mm L=797 mm | 450 | 797 | 25 | 3 | 1,2 |

2 P.THG30.3.L797 11 THG30 rack 3 mm L=797 mm 12 13 RAW_P.THG30.0.L0000.jpg 14 10 CAT_P.THG30.3.L0000_2D.gif | ||||||

| P.THG30.3.L998 | THG30 rack 3 mm L=998 mm | 450 | 998 | 25 | 3 | 1,5 |

2 P.THG30.3.L998 11 THG30 rack 3 mm L=998 mm 12 13 RAW_P.THG30.0.L0000.jpg 14 10 CAT_P.THG30.3.L0000_2D.gif | ||||||

| P.THG30.3.L1099 | THG30 rack 3 mm L=1099 mm | 450 | 1099 | 25 | 3 | 1,7 |

2 P.THG30.3.L1099 11 THG30 rack 3 mm L=1099 mm 12 13 RAW_P.THG30.0.L0000.jpg 14 10 CAT_P.THG30.3.L0000_2D.gif | ||||||

| P.THG30.3.L1250 | THG30 rack 3 mm L=1250 mm | 450 | 1250 | 25 | 3 | 1,9 |

2 P.THG30.3.L1250 11 THG30 rack 3 mm L=1250 mm 12 13 RAW_P.THG30.0.L0000.jpg 14 10 CAT_P.THG30.3.L0000_2D.gif | ||||||

| P.THG30.3.L1300 | THG30 rack 3 mm L=1300 mm | 450 | 1300 | 25 | 3 | 2,0 |

2 P.THG30.3.L1300 11 THG30 rack 3 mm L=1300 mm 12 13 RAW_P.THG30.0.L0000.jpg 14 10 CAT_P.THG30.3.L0000_2D.gif | ||||||

| P.THG30.3.L1400 | THG30 rack 3 mm L=1400 mm | 450 | 1400 | 25 | 3 | 2,2 |

2 P.THG30.3.L1400 11 THG30 rack 3 mm L=1400 mm 12 13 RAW_P.THG30.0.L0000.jpg 14 10 CAT_P.THG30.3.L0000_2D.gif | ||||||

| P.THG30.3.L1451 | THG30 rack 3 mm L=1451 mm | 450 | 1451 | 25 | 3 | 2,2 |

2 P.THG30.3.L1451 11 THG30 rack 3 mm L=1451 mm 12 13 RAW_P.THG30.0.L0000.jpg 14 10 CAT_P.THG30.3.L0000_2D.gif | ||||||

| P.THG30.3.L1500 | THG30 rack 3 mm L=1500 mm | 450 | 1500 | 25 | 3 | 2,2 |

2 P.THG30.3.L1500 11 THG30 rack 3 mm L=1500 mm 12 13 RAW_P.THG30.0.L0000.jpg 14 10 CAT_P.THG30.3.L0000_2D.gif | ||||||

| P.THG30.3.L1652 | THG30 rack 3 mm L=1652 mm | 450 | 1652 | 25 | 3 | 2,5 |

2 P.THG30.3.L1652 11 THG30 rack 3 mm L=1652 mm 12 13 RAW_P.THG30.0.L0000.jpg 14 10 CAT_P.THG30.3.L0000_2D.gif | ||||||

| P.THG30.3.L1953 | THG30 rack 3 mm L=1953 mm | 450 | 1953 | 25 | 3 | 3,0 |

2 P.THG30.3.L1953 11 THG30 rack 3 mm L=1953 mm 12 13 RAW_P.THG30.0.L0000.jpg 14 10 CAT_P.THG30.3.L0000_2D.gif |

Window bracket set

| Article | Article name | m [kg] |

| P.THG30.RB | THG30 aluminium window bracket | 0,06 |

Slide bearing plate

| Article | Description | A [mm] | H [mm] | L [mm] | m [kg] |

| P.GL100.H.L120 | Slide bearing plate 1" H A062 L120 mm | 62 | 95 | 120 | 0,1 |

Drive systems for ventilation

A healthy building environment determines the livestock' productivity, growth, food consumption, stress levels and infection risks. Fresh air is vital important, where it enters in an optimal direction, at the right height and speed. For this we offer the highly innovative KL300 MultiWinch, which is specifically designed for this form of ventilation. The well-known GW series combined with winch drums or TGA rack and pinion is the solution for opening and closing tunnel doors.

De Gier Drive Systems

+ 31 174 29 20 89