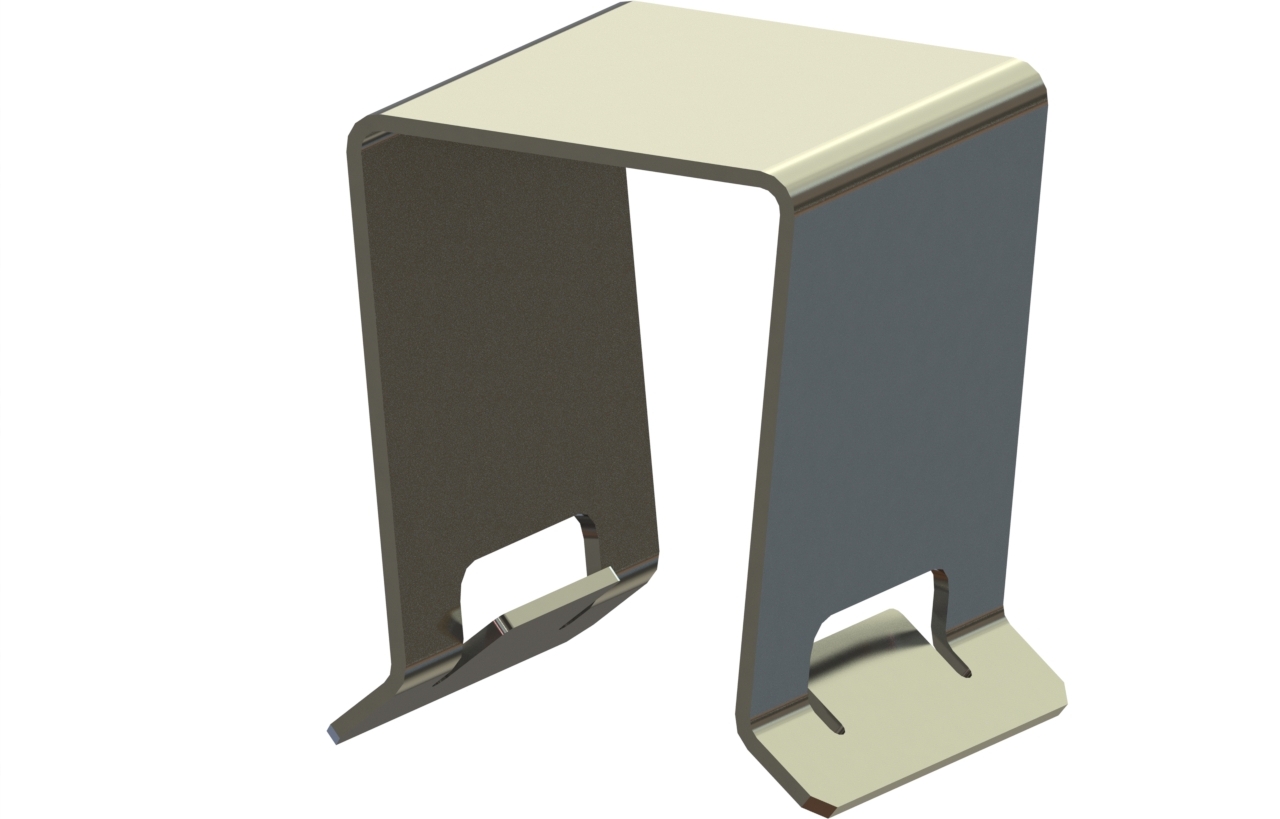

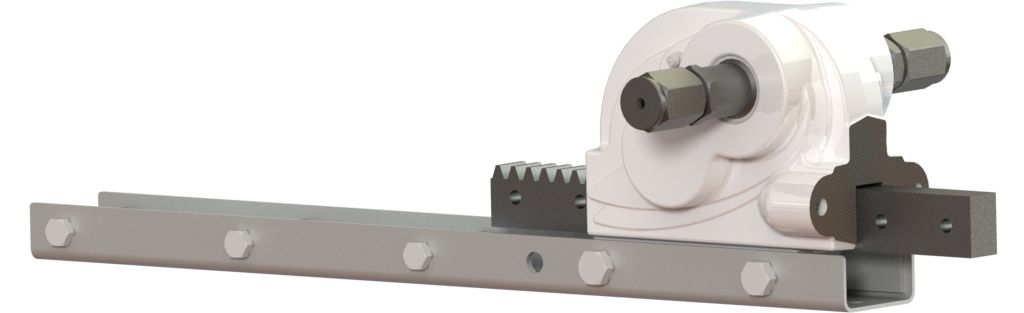

Truss-rail ventilation column mounting - P.THG25-42RK

We are happy to help you with making a calculation

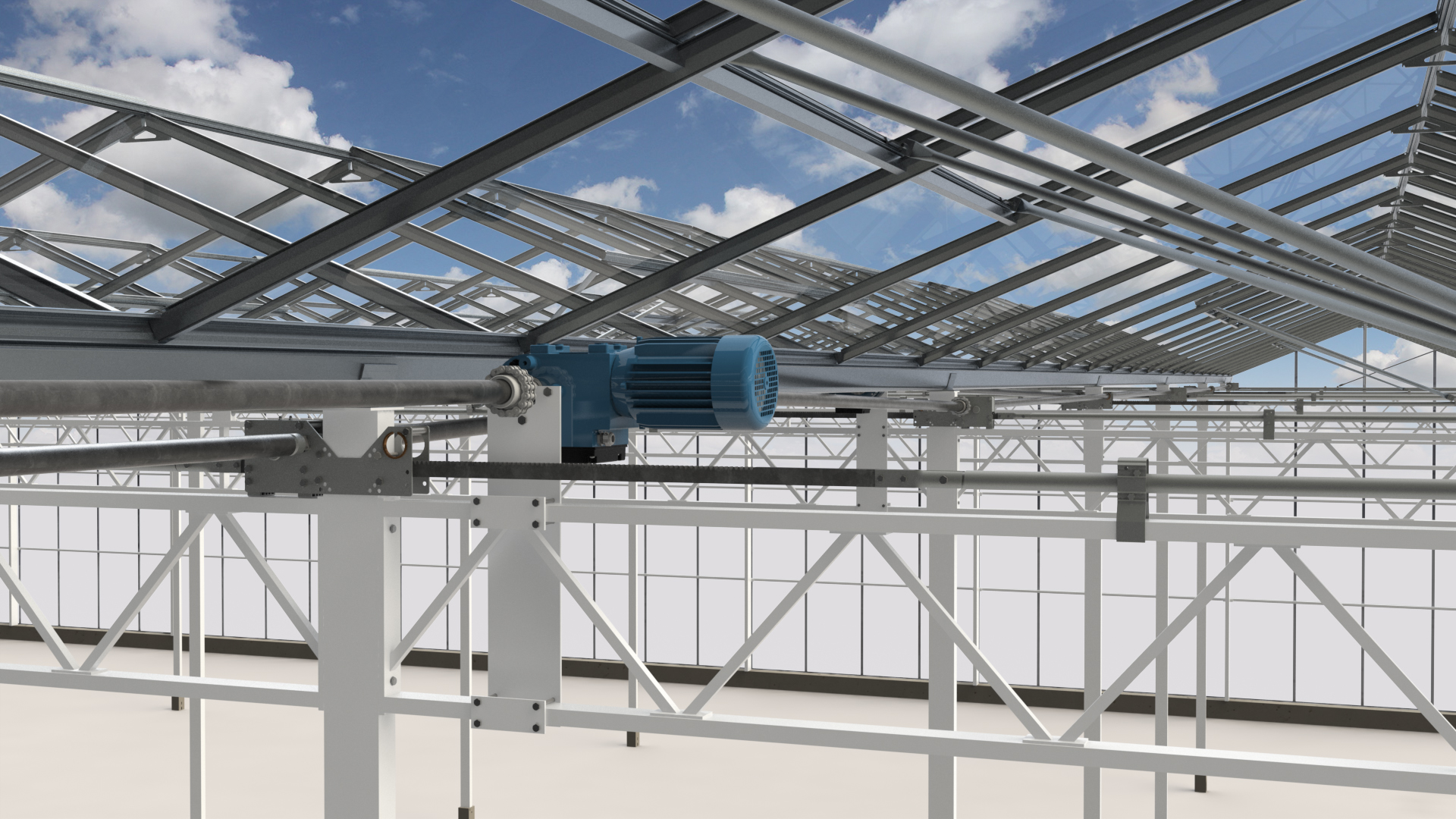

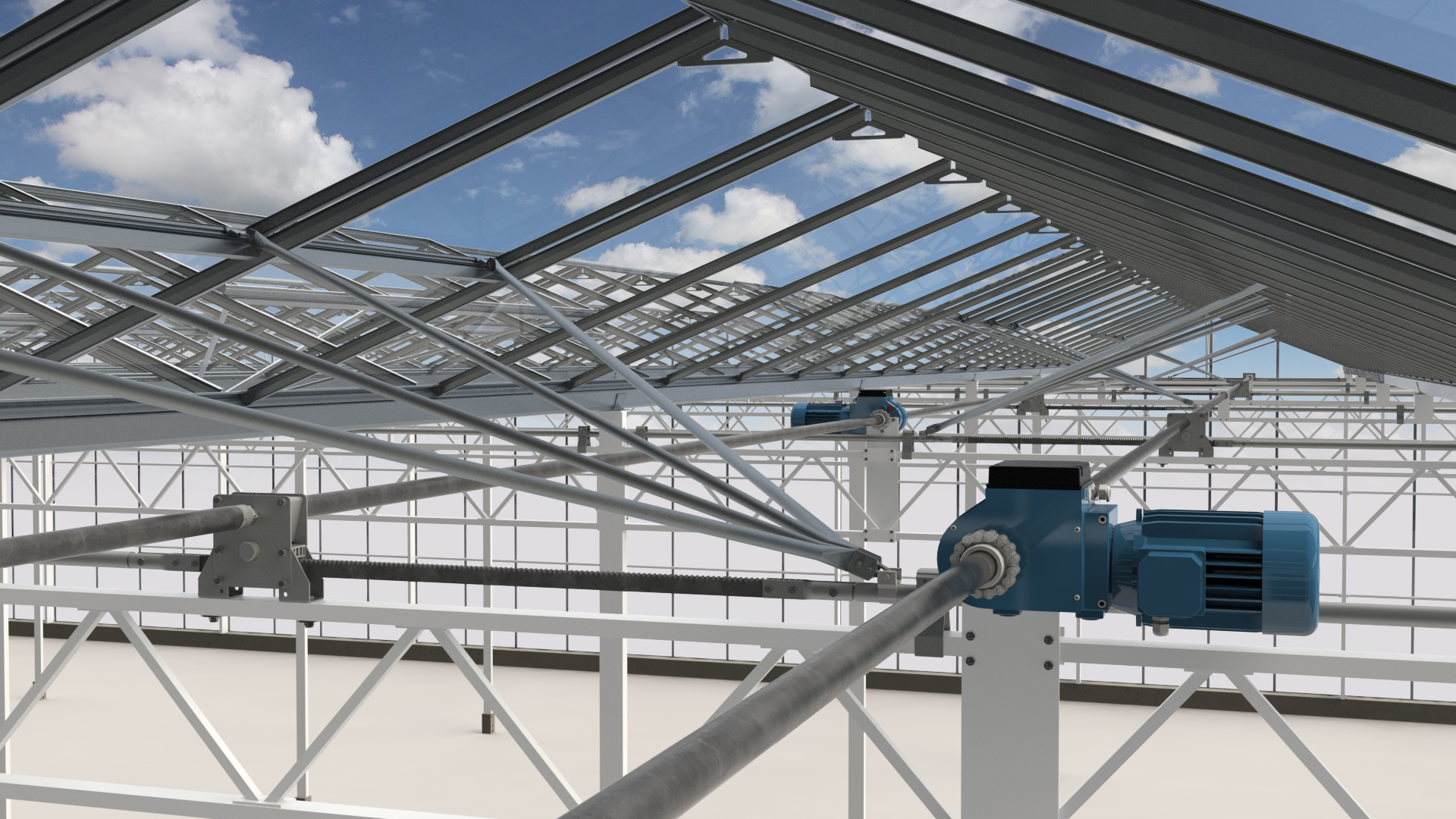

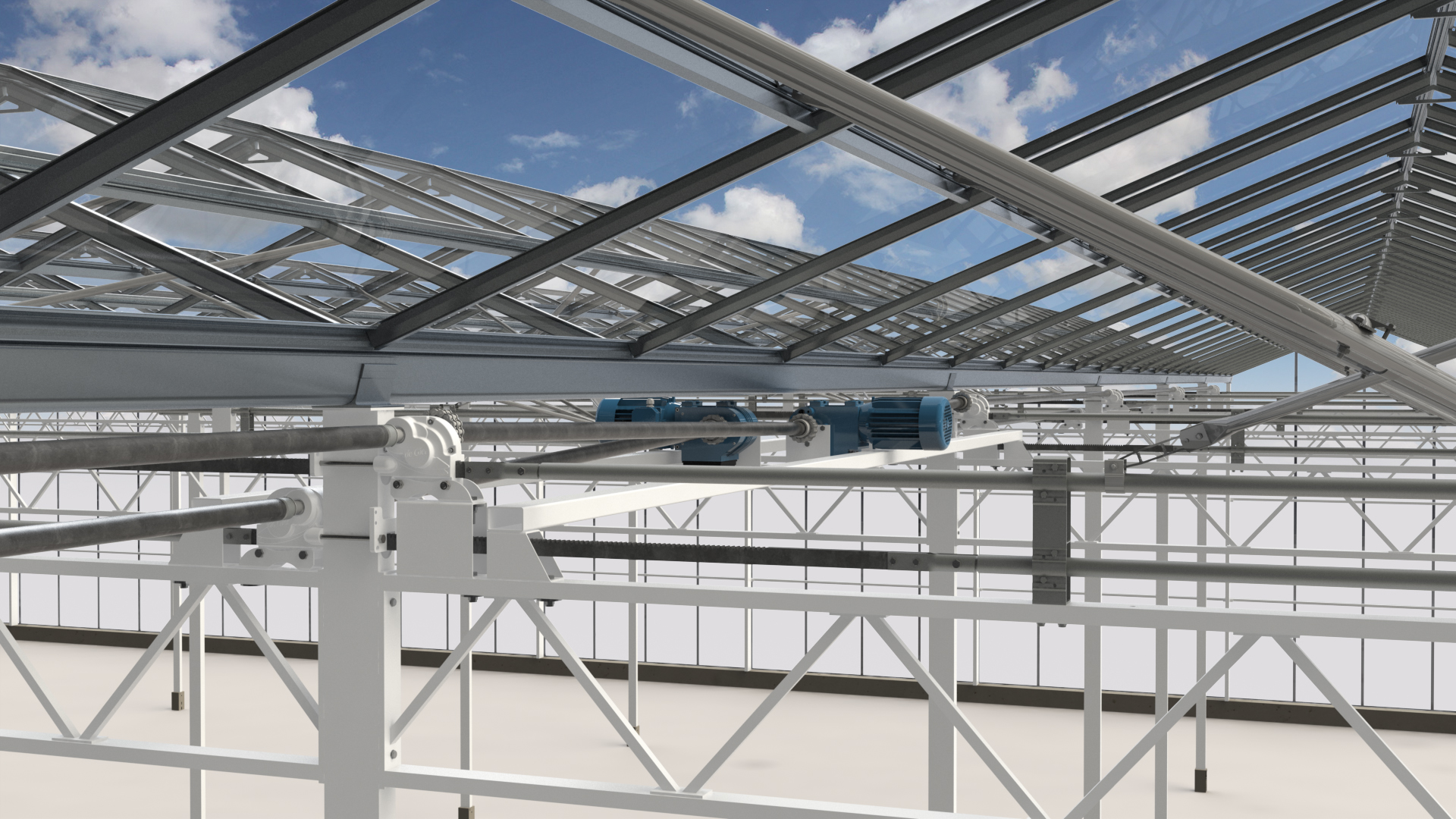

Get in contact with usTruss-rail ventilation systems are used for natural ventilation in Venlo greenhouses. With the RK system, the rack boxes are fixed around the column. One gear rack moves a push-pull tube with push rods that operates one row of ventilation windows in a section. The lee- or wind-side ventilation gear racks are coupled with drive tubes and driven by a GW motor gearbox.

- Ideal installation location, minimal shading.

- Very easy to mount around the column.

- Ideal force transfer onto the column.

- Features integrated 5/4" shaft bearing.

- Suitable for 5/4" prefabricated drive shafts.

- Highly suitable for light and medium loads (5000/8500 N).

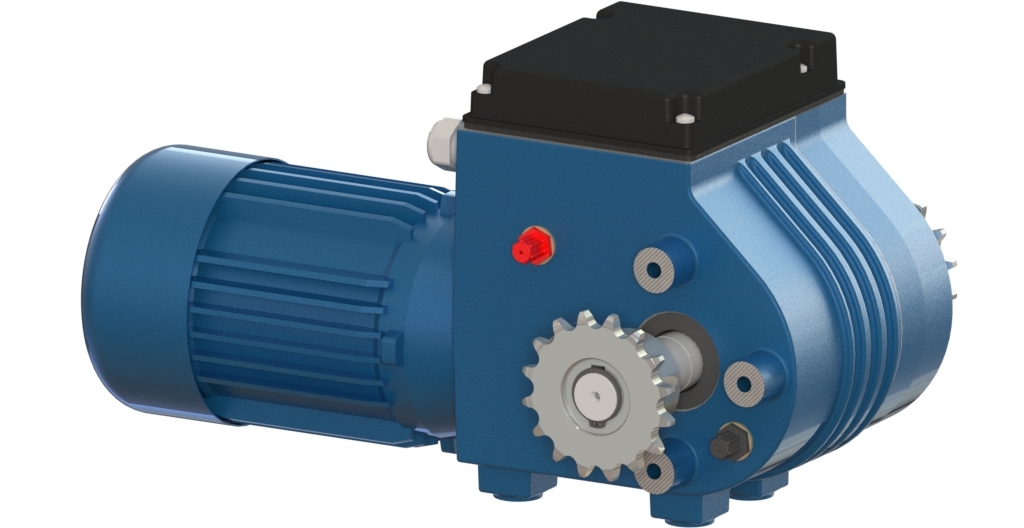

GW motor gearbox

| Article | Description | T (50/60Hz) [Nm] | n (50/60Hz) [rpm] | L [mm] | D [mm] | P (50/60Hz) [kW] | I (@ Y) (50/60Hz) [A] | I (@ Δ) (50/60Hz) [A] | m [kg] |

| P.GW10.3.400.26.KW | GW10 2.6 3ph 400V with CW+CH 10B z16 | 100 / 80 | 2,6 / 3,1 | 168 | 124 | 0,09 / 0,11 | 0,4 / 0,4 | 0,7 / 0,7 | 21 |

2 P.GW10.3.400.26.KW 11 GW10 2.6 3ph 400V with CW+CH 10B z16 12 13 P.GW10.400.26.KW.jpg 14 15 CAT_P.GW10.400.26.KW_2D.gif 17 16 10 | |||||||||

| P.GW10.3.400.52.KW | GW10 5.2 3ph 400V with CW+CH 10B z16 | 100 / 80 | 5,2 / 6,2 | 191 | 124 | 0,18 / 0,22 | 0,7 / 0,7 | 1,2 / 1,2 | 24 |

2 P.GW10.3.400.52.KW 11 GW10 5.2 3ph 400V with CW+CH 10B z16 12 13 P.GW10.400.26.KW.jpg 14 15 CAT_P.GW10.400.26.KW_2D.gif 17 16 10 | |||||||||

| P.GW30.400.26.KW | GW30 2.6 3ph 400V with CW+CH 10B z16 | 300 / 240 | 2,6 / 3,1 | 220 | 145 | 0,25 / 0,30 | 0,8 / 0,8 | 1,4 / 1,4 | 24 |

2 P.GW30.400.26.KW 11 GW30 2.6 3ph 400V with CW+CH 10B z16 12 13 P.GW30.400.26.KW.jpg 14 15 CAT_P.GW30.400.26.KW_2D.gif 17 16 10 | |||||||||

| P.GW30.400.52.KW | GW30 5.2 3ph 400V with CW+CH 10B z16 | 300 / 240 | 5,2 / 6,2 | 220 | 145 | 0,37 / 0,44 | 1,2 / 1,2 | 2,1 / 2,1 | 27 |

2 P.GW30.400.52.KW 11 GW30 5.2 3ph 400V with CW+CH 10B z16 12 13 P.GW30.400.26.KW.jpg 14 15 CAT_P.GW30.400.26.KW_2D.gif 17 16 10 | |||||||||

| P.GW40.400.26.KW | GW40 2.6 3ph 400V with CW+CH 10B z16 | 400 / 320 | 2,6 / 3,1 | 220 | 159 | 0,37 / 0,44 | 1,0 / 1,0 | 1,7 / 1,7 | 29 |

2 P.GW40.400.26.KW 11 GW40 2.6 3ph 400V with CW+CH 10B z16 12 13 P.GW80.400.26.KW.jpg 14 15 CAT_P.GW80.400.26.KW_2D.gif 17 16 10 | |||||||||

| P.GW40.3.400.52.KW | GW40 5.2 3ph 400V with CW+CH 10B z16 | 400 / 320 | 5,2 / 6,2 | 220 | 137 | 0,55 / 0,66 | 1,5 / 1,5 | 2,6 / 2,6 | 29 |

2 P.GW40.3.400.52.KW 11 GW40 5.2 3ph 400V with CW+CH 10B z16 12 13 P.GW80.400.26.KW.jpg 14 15 CAT_P.GW80.400.26.KW_2D.gif 17 16 10 | |||||||||

| P.GW80.400.26.KW | GW80 2.6 3ph 400V with CW+CH 10B z16 | 800 / 640 | 2,6 / 3,1 | 218 | 159 | 0,55 / 0,66 | 1,5 / 1,5 | 2,6 / 2,6 | 31 |

2 P.GW80.400.26.KW 11 GW80 2.6 3ph 400V with CW+CH 10B z16 12 13 P.GW80.400.26.KW.jpg 14 15 CAT_P.GW80.400.26.KW_2D.gif 17 16 10 | |||||||||

| P.GW80.2.400.40.KW | GW80 4.0 3ph 400V with CW+CH 10B z16 d25 | 800 / 640 | 4,0 / 4,8 | 242 | 159 | 0,75 / 0,90 | 2,0 / 2,0 | 3,5 / 3,5 | 38 |

2 P.GW80.2.400.40.KW 11 GW80 4.0 3ph 400V with CW+CH 10B z16 d25 12 13 P.GW80.400.26.KW.jpg 14 15 CAT_P.GW80.400.26.KW_2D.gif 17 16 10 | |||||||||

| P.GW100.400.26.KW | GW100 2.6 3ph 400V with CW+CH 12B z18 | 1000 / 800 | 2,6 / 3,1 | 242 | 159 | 0,75 / 0,90 | 2,2 / 2,2 | 3,8 / 3,8 | 38 |

2 P.GW100.400.26.KW 11 GW100 2.6 3ph 400V with CW+CH 12B z18 12 13 P.GW150S.400.40.KW.jpg 14 15 CAT_P.GW100.400.26.KW_2D.gif 17 16 10 |

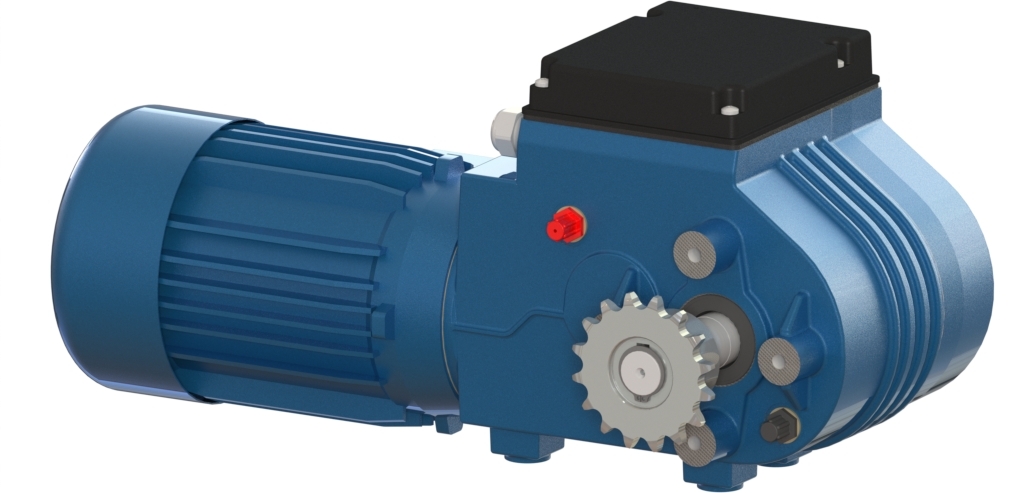

Rack box

| Article | Description | F [N] | T [Nm] | i [-] | L [mm] | S [mm] | s [mm/rev] | n [rev] | Bk [mm] | B [mm] | m [kg] |

| P.THG25RK.S0750 | THG25RK, L1260 S0750mm | 5000 | 32,50 | 2,760 | 1260 | 750 | 36,35 | 21 | 50 | 150 | 9,0 |

2 P.THG25RK.S0750 11 THG25RK, L1260 S0750mm 12 13 P.THG25RK.S0000.jpg 14 15 CAT_P.THG25RK.S0000_2D.gif 16 17 18 19 9,0 10 5000 | |||||||||||

| P.THG25RK.S0900 | THG25RK, L1410 S0900mm | 5000 | 32,50 | 2,760 | 1410 | 900 | 36,35 | 25 | 50 | 150 | 9,5 |

2 P.THG25RK.S0900 11 THG25RK, L1410 S0900mm 12 13 P.THG25RK.S0000.jpg 14 15 CAT_P.THG25RK.S0000_2D.gif 16 17 18 19 9,5 10 5000 | |||||||||||

| P.THG25RK.S1100 | THG25RK, L1610 S1100mm | 5000 | 32,50 | 2,760 | 1610 | 1100 | 36,35 | 31 | 50 | 150 | 10,0 |

2 P.THG25RK.S1100 11 THG25RK, L1610 S1100mm 12 13 P.THG25RK.S0000.jpg 14 15 CAT_P.THG25RK.S0000_2D.gif 16 17 18 19 10,0 10 5000 | |||||||||||

| P.THG42RK.S0750 | THG42RK, L1260 S0750mm | 8500 | 55,25 | 2,760 | 1260 | 750 | 36,35 | 21 | 50 | 150 | 10,0 |

2 P.THG42RK.S0750 11 THG42RK, L1260 S0750mm 12 13 P.THG42RK.S0000.jpg 14 15 CAT_P.THG42RK.S0000_2D.gif 16 17 18 19 10,0 10 8500 | |||||||||||

| P.THG42RK.S0900 | THG42RK, L1410 S0900mm | 8500 | 55,25 | 2,760 | 1410 | 900 | 36,35 | 25 | 50 | 150 | 10,5 |

2 P.THG42RK.S0900 11 THG42RK, L1410 S0900mm 12 13 P.THG42RK.S0000.jpg 14 15 CAT_P.THG42RK.S0000_2D.gif 16 17 18 19 10,5 10 8500 | |||||||||||

| P.THG42RK.S1100 | THG42RK, L1610 S1100mm | 8500 | 55,25 | 2,760 | 1610 | 1100 | 36,35 | 31 | 50 | 150 | 11,0 |

2 P.THG42RK.S1100 11 THG42RK, L1610 S1100mm 12 13 P.THG42RK.S0000.jpg 14 15 CAT_P.THG42RK.S0000_2D.gif 16 17 18 19 11,0 10 8500 |

Coupling set

| Article | Description | D [mm] | B [mm] | m [kg] |

| P.SKP.D27 | Coupling set D27 for THG25/42/55 rack | 27 | 15 / 20 | 0,2 |

| P.SKP.D32 | Coupling set D32 for THG25/42/55 rack | 32 | 15 / 20 | 0,2 |

Coupling set fastener

| Article | Description | B [mm] | m [kg] |

| P.SKP.BVM.15 | BVM coupling set - THG25 rack | 35 | 0,03 |

| P.SKP.BVM.20 | BVM coupling set - THG42/55 rack | 35 | 0,03 |

Locking

| Article | Description | m [kg] |

| P.AS-BORGCLIP | Axle securing clip | 0,01 |

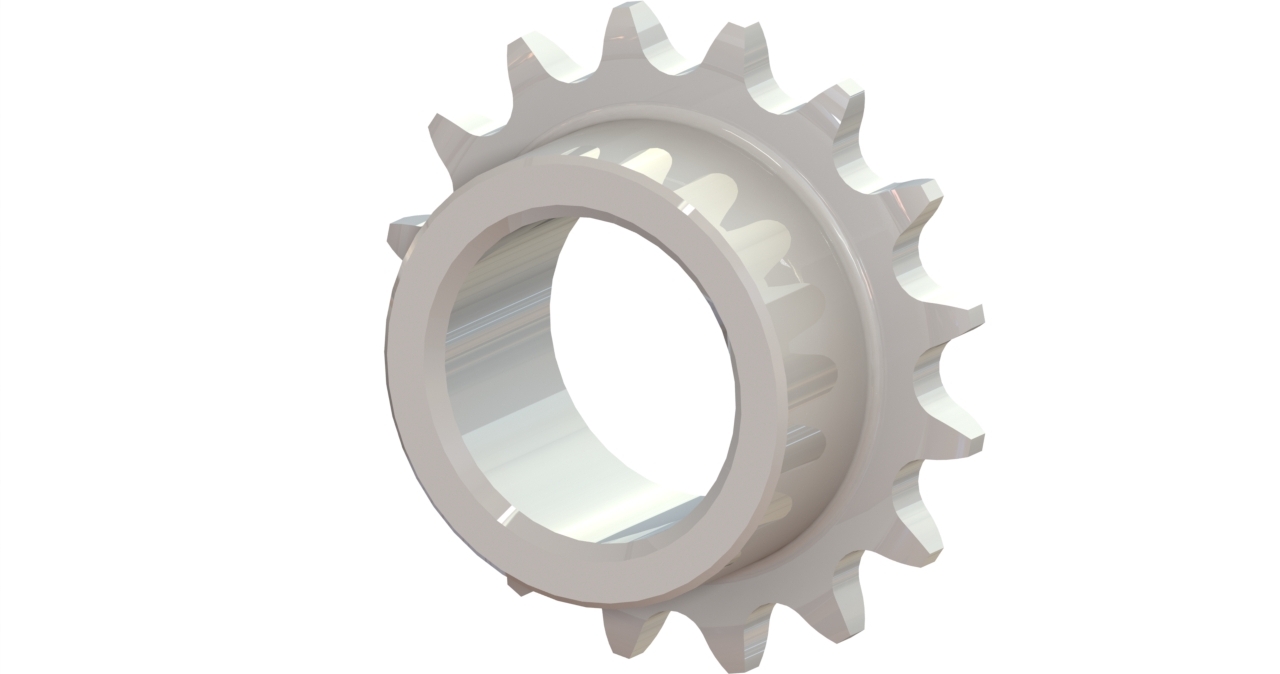

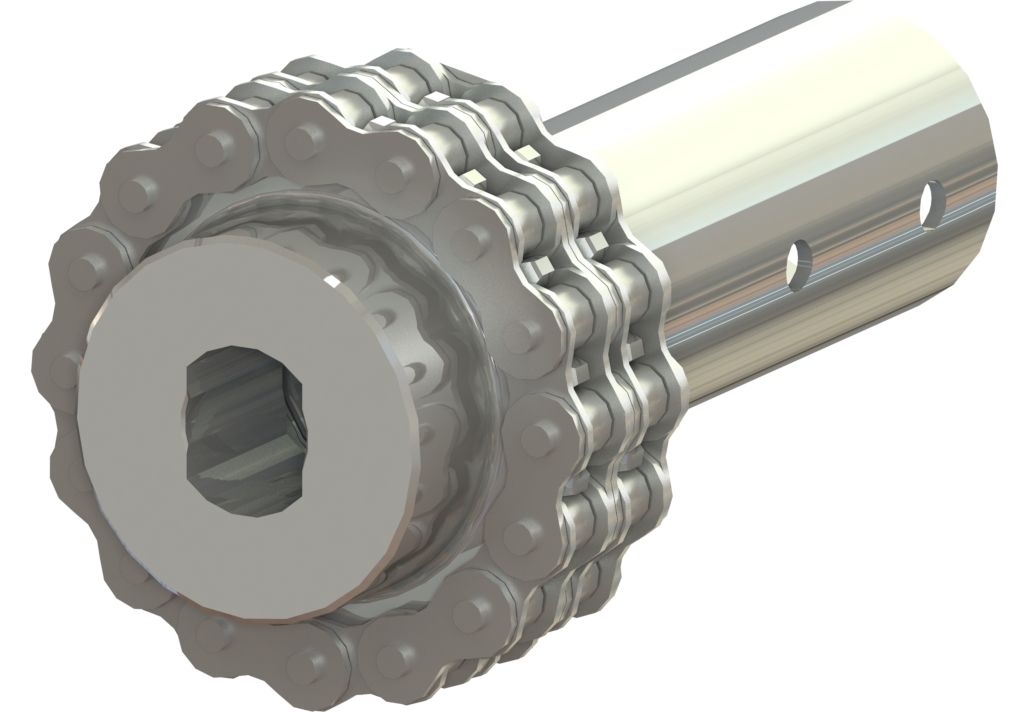

Weld sprockets

| Article | Description | Chain | Shaft | Tmax [Nm] | Db [mm] | D [mm] | L [mm] | m [kg] |

| P.LKWL10B.Z16.D125 | Weld sprocket 10B z16 - 5/4" | 10B z16 | D125 | 420 | 43 | 96 | 30 | 0,4 |

2 P.LKWL10B.Z16.D125 11 Weld sprocket 10B z16 - 5/4" 12 13 P.LKWL10B.Z16.D125.jpg 15 16 CAT_P.LKWL10B.Z16.D125_2D.gif 17 10 |

Chains

| Article | Description | Tmax [Nm] | D [mm] | m [kg] |

| P.KTG10B-2.Z16 | Chain 10B z16 | 420 | 96 | 0,5 |

| P.KTG12B-2.Z18 | Chain 12B z18 | 760 | 126 | 0,8 |

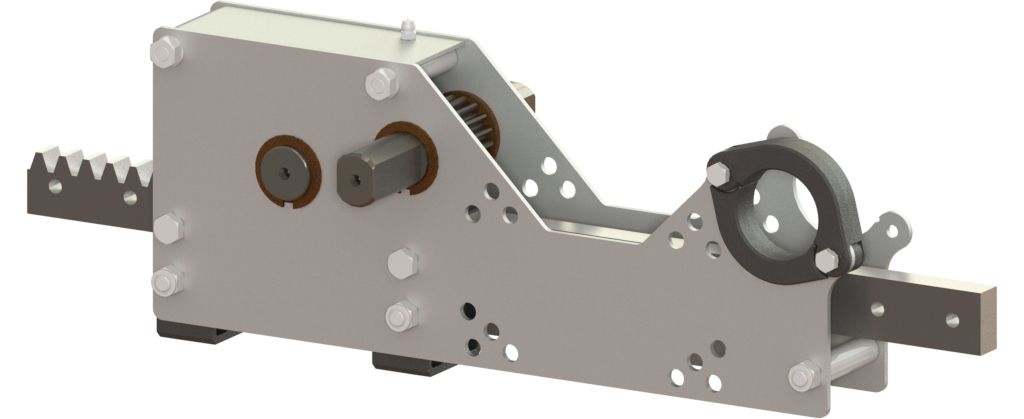

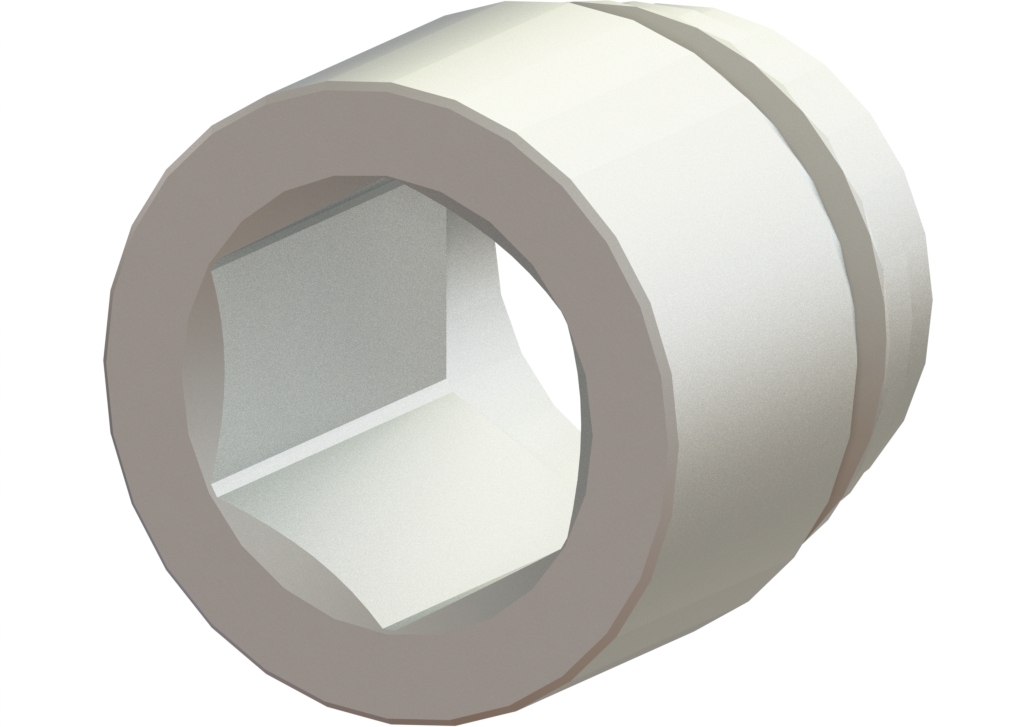

Sleeve sprockets for THG25-42RK

| Article | Description | Chain | Shaft | Tmax [Nm] | D2 [mm] | L [mm] | m [kg] |

| P.KWL10B.Z16.S20 | Sleeve sprocket 10B z16 p5/8" s20 | 10B z16 | S20 | 240 | 77 | 27 | 0,4 |

2 P.KWL10B.Z16.S20 11 Sleeve sprocket 10B z16 p5/8" s20 12 13 P.KWL10B.Z16.S20.jpg 14 15 CAT_P.KWL10B.Z16.S20_2D.gif 10 |

Sleeve joint coupling prefab

| Article | Description | Db [mm] | Type | m [kg] |

| P.SLKP125.S20 | Prefab sleeve joint coupling 5/4" - S20 | 42,4 | S20 | 0,2 |

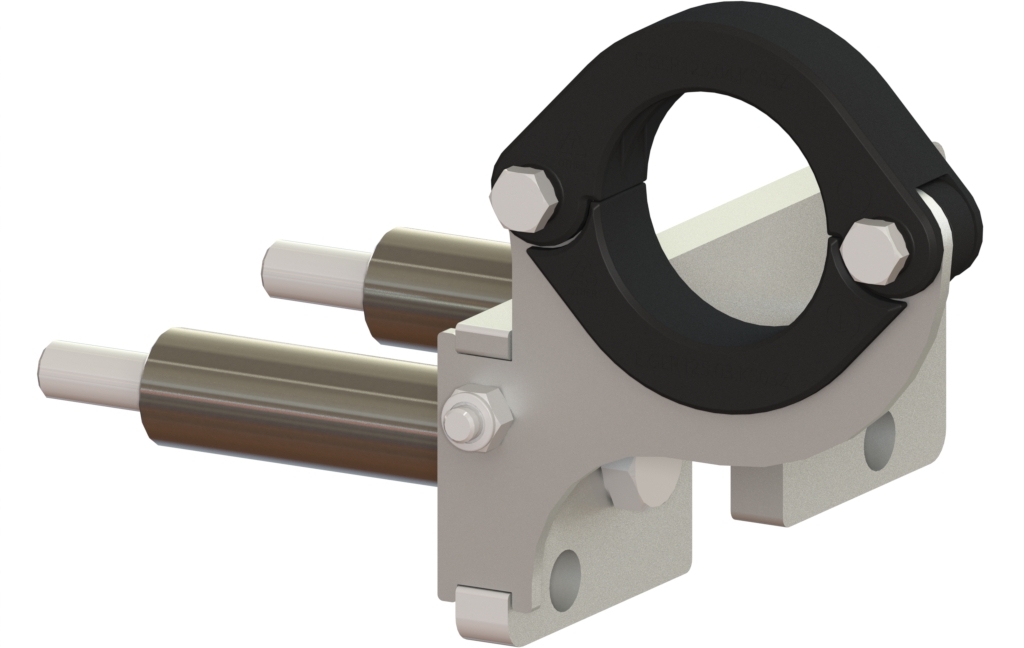

Clamping mounting plates RK

| Article | Description | H [mm] | B [mm] | A [mm] | L [mm] | m [kg] |

| P.MP.RK.KL.350.25 | Clamping mounting pl. RK 350 truss 25 | 350 | 25 | 205 | 581 | 4,0 |

2 P.MP.RK.KL.350.25 11 Clamping mounting pl. RK 350 truss 25 12 13 P.MP.RK.KL.400.30.jpg 14 10 CAT_P.MP.RK.KL.000.00_2D.gif | ||||||

| P.MP.RK.KL.400.30 | Clamping mounting pl. RK 400 truss 30 | 400 | 30 | 205 | 631 | 5,1 |

2 P.MP.RK.KL.400.30 11 Clamping mounting pl. RK 400 truss 30 12 13 P.MP.RK.KL.400.30.jpg 14 10 CAT_P.MP.RK.KL.000.00_2D.gif | ||||||

| P.MP.RK.KL.500.30 | Clamping mounting pl. RK 500 truss 30 | 500 | 30 | 205 | 731 | 5,8 |

2 P.MP.RK.KL.500.30 11 Clamping mounting pl. RK 500 truss 30 12 13 P.MP.RK.KL.400.30.jpg 14 10 CAT_P.MP.RK.KL.000.00_2D.gif | ||||||

| P.MP.RK.KL.600.30 | Clamping mounting pl. RK 600 truss 30 | 600 | 30 | 205 | 831 | 6,5 |

2 P.MP.RK.KL.600.30 11 Clamping mounting pl. RK 600 truss 30 12 13 P.MP.RK.KL.400.30.jpg 14 10 CAT_P.MP.RK.KL.000.00_2D.gif | ||||||

| P.MP.RK.KL.400.25 | Clamping mounting pl. RK 350 truss 25 | 400 | 25 | 205 | 631 | 5,1 |

2 P.MP.RK.KL.400.25 11 Clamping mounting pl. RK 350 truss 25 12 13 P.MP.RK.KL.400.30.jpg 14 10 CAT_P.MP.RK.KL.000.00_2D.gif |

Multiple options available upon request

Drive systems for ventilation

Rapidly varying weather conditions are the order of the day. The need for good, accurate ventilation systems and airtightness in larger production greenhouses is becoming increasingly important. New cultivation requires insights for less, accurate and metered ventilation in combination with more screens with the aim of keeping as much heat and moisture as possible in the greenhouse to save energy. To achieve an optimal climate through optimal ventilation, our drives are essential for optimal results.

End-wall ventilation in combination with RK - P.THG25RKGC

We are happy to help you with making a calculation

Get in contact with usEndwall truss-rail ventilation systems are used for extra ventilation in the endwall section. With the RKGC system, the rack boxes are placed close to the gutter and fixed on a C-profile between the gutters. These gear racks move one row of endwall ventilation windows in a section. The gear racks are driven by a GW motor gearbox via drive tubes with chain couplings for the necessary angle correction. - Better climate in the endwall section.

- Better climate in the head compartments.

- Ideal installation location gives minimal shading.

- Very easy installation on standard C-profile.

- Suitable for 5/4" prefabricated drive shafts.

- Highly suitable for light and medium loads.

Rack box

| Article | Description | F [N] | T [Nm] | i [-] | L [mm] | S [mm] | s [mm/rev] | n [rev] | m [kg] |

| P.THG25RKGC.S0750 | THG25RKGC, L1260 S0750mm | 5000 | 32,50 | 2,760 | 1260 | 750 | 36,35 | 21 | 8,0 |

2 P.THG25RKGC.S0750 11 THG25RKGC, L1260 S0750mm 12 13 P.THG25RKGC.S0000.jpg 14 15 CAT_P.THG25RKGC.S0000_2D.gif 16 17 10 | |||||||||

| P.THG25RKGC.S0900 | THG25RKGC, L1410 S0900mm | 5000 | 32,50 | 2,760 | 1410 | 900 | 36,35 | 25 | 8,5 |

2 P.THG25RKGC.S0900 11 THG25RKGC, L1410 S0900mm 12 13 P.THG25RKGC.S0000.jpg 14 15 CAT_P.THG25RKGC.S0000_2D.gif 16 17 10 | |||||||||

| P.THG25RKGC.S1100 | THG25RKGC, L1610 S1100mm | 5000 | 32,50 | 2,760 | 1610 | 1100 | 36,35 | 31 | 9,0 |

2 P.THG25RKGC.S1100 11 THG25RKGC, L1610 S1100mm 12 13 P.THG25RKGC.S0000.jpg 14 15 CAT_P.THG25RKGC.S0000_2D.gif 16 17 10 |

Coupling set

| Article | Description | D [mm] | B [mm] | m [kg] |

| P.SKP.D27 | Coupling set D27 for THG25/42/55 rack | 27 | 15 / 20 | 0,2 |

| P.SKP.D32 | Coupling set D32 for THG25/42/55 rack | 32 | 15 / 20 | 0,2 |

Coupling set fastener

| Article | Description | B [mm] | m [kg] |

| P.SKP.BVM.15 | BVM coupling set - THG25 rack | 35 | 0,03 |

Locking

| Article | Description | m [kg] |

| P.AS-BORGCLIP | Axle securing clip | 0,01 |

Weld sprockets

| Article | Description | Chain | Shaft | Tmax [Nm] | Db [mm] | D [mm] | L [mm] | m [kg] |

| P.LKWL10B.Z16.D125 | Weld sprocket 10B z16 - 5/4" | 10B z16 | D125 | 420 | 43 | 96 | 30 | 0,4 |

2 P.LKWL10B.Z16.D125 11 Weld sprocket 10B z16 - 5/4" 12 13 P.LKWL10B.Z16.D125.jpg 15 16 CAT_P.LKWL10B.Z16.D125_2D.gif 17 10 |

Chains

| Article | Description | Tmax [Nm] | D [mm] | m [kg] |

| P.KTG10B-2.Z16 | Chain 10B z16 | 420 | 96 | 0,5 |

Tube bolt chain coupling on THG25RKGC

| Article | Description | Tmax [Nm] | D2 [mm] | D3 [mm] | L1 [mm] | L3 [mm] | m [kg] |

| P.BBKK10B.S20.D125 | Tube bolt CC set 10B S20 z16 5/4" | 420 | 43,1 | 96 | 30 | 150 | 1,9 |

2 P.BBKK10B.S20.D125 13 Tube bolt CC set 10B S20 z16 5/4" 17 18 P.BBKK10B.S20.D000.jpg 20 21 CAT_P.BBKK10B.D00.D125_2D.gif 10 |

Drive systems for ventilation

Rapidly varying weather conditions are the order of the day. The need for good, accurate ventilation systems and airtightness in larger production greenhouses is becoming increasingly important. New cultivation requires insights for less, accurate and metered ventilation in combination with more screens with the aim of keeping as much heat and moisture as possible in the greenhouse to save energy. To achieve an optimal climate through optimal ventilation, our drives are essential for optimal results.

Truss-rail ventilation column mounting - P.THG55RK

We are happy to help you with making a calculation

Get in contact with usTruss-rail ventilation systems are used for natural ventilation in Venlo greenhouses. With the RK system, the rack boxes are fixed around the column. One gear rack moves a push-pull tube with push rods that operates one row of ventilation windows in a section. The lee- or wind-side ventilation gear racks are coupled with drive tubes and driven by a GW motor gearbox.

- Ideal installation location gives minimal shading.

- Easy mounting around the column.

- Ideal force transfer onto the column.

- Suitable for 5/4" prefabricated drive shafts.

- Suitable for medium load (11,000 N).

GW motor gearbox

| Article | Description | T (50/60Hz) [Nm] | n (50/60Hz) [rpm] | L [mm] | D [mm] | P (50/60Hz) [kW] | I (@ Y) (50/60Hz) [A] | I (@ Δ) (50/60Hz) [A] | m [kg] |

| P.GW10.3.400.26.KW | GW10 2.6 3ph 400V with CW+CH 10B z16 | 100 / 80 | 2,6 / 3,1 | 168 | 124 | 0,09 / 0,11 | 0,4 / 0,4 | 0,7 / 0,7 | 21 |

2 P.GW10.3.400.26.KW 11 GW10 2.6 3ph 400V with CW+CH 10B z16 12 13 P.GW10.400.26.KW.jpg 14 15 CAT_P.GW10.400.26.KW_2D.gif 17 16 10 | |||||||||

| P.GW10.3.400.52.KW | GW10 5.2 3ph 400V with CW+CH 10B z16 | 100 / 80 | 5,2 / 6,2 | 191 | 124 | 0,18 / 0,22 | 0,7 / 0,7 | 1,2 / 1,2 | 24 |

2 P.GW10.3.400.52.KW 11 GW10 5.2 3ph 400V with CW+CH 10B z16 12 13 P.GW10.400.26.KW.jpg 14 15 CAT_P.GW10.400.26.KW_2D.gif 17 16 10 | |||||||||

| P.GW30.400.26.KW | GW30 2.6 3ph 400V with CW+CH 10B z16 | 300 / 240 | 2,6 / 3,1 | 220 | 145 | 0,25 / 0,30 | 0,8 / 0,8 | 1,4 / 1,4 | 24 |

2 P.GW30.400.26.KW 11 GW30 2.6 3ph 400V with CW+CH 10B z16 12 13 P.GW30.400.26.KW.jpg 14 15 CAT_P.GW30.400.26.KW_2D.gif 17 16 10 | |||||||||

| P.GW30.400.52.KW | GW30 5.2 3ph 400V with CW+CH 10B z16 | 300 / 240 | 5,2 / 6,2 | 220 | 145 | 0,37 / 0,44 | 1,2 / 1,2 | 2,1 / 2,1 | 27 |

2 P.GW30.400.52.KW 11 GW30 5.2 3ph 400V with CW+CH 10B z16 12 13 P.GW30.400.26.KW.jpg 14 15 CAT_P.GW30.400.26.KW_2D.gif 17 16 10 | |||||||||

| P.GW40.400.26.KW | GW40 2.6 3ph 400V with CW+CH 10B z16 | 400 / 320 | 2,6 / 3,1 | 220 | 159 | 0,37 / 0,44 | 1,0 / 1,0 | 1,7 / 1,7 | 29 |

2 P.GW40.400.26.KW 11 GW40 2.6 3ph 400V with CW+CH 10B z16 12 13 P.GW80.400.26.KW.jpg 14 15 CAT_P.GW80.400.26.KW_2D.gif 17 16 10 | |||||||||

| P.GW40.3.400.52.KW | GW40 5.2 3ph 400V with CW+CH 10B z16 | 400 / 320 | 5,2 / 6,2 | 220 | 137 | 0,55 / 0,66 | 1,5 / 1,5 | 2,6 / 2,6 | 29 |

2 P.GW40.3.400.52.KW 11 GW40 5.2 3ph 400V with CW+CH 10B z16 12 13 P.GW80.400.26.KW.jpg 14 15 CAT_P.GW80.400.26.KW_2D.gif 17 16 10 | |||||||||

| P.GW80.400.26.KW | GW80 2.6 3ph 400V with CW+CH 10B z16 | 800 / 640 | 2,6 / 3,1 | 218 | 159 | 0,55 / 0,66 | 1,5 / 1,5 | 2,6 / 2,6 | 31 |

2 P.GW80.400.26.KW 11 GW80 2.6 3ph 400V with CW+CH 10B z16 12 13 P.GW80.400.26.KW.jpg 14 15 CAT_P.GW80.400.26.KW_2D.gif 17 16 10 | |||||||||

| P.GW80.2.400.40.KW | GW80 4.0 3ph 400V with CW+CH 10B z16 d25 | 800 / 640 | 4,0 / 4,8 | 242 | 159 | 0,75 / 0,90 | 2,0 / 2,0 | 3,5 / 3,5 | 38 |

2 P.GW80.2.400.40.KW 11 GW80 4.0 3ph 400V with CW+CH 10B z16 d25 12 13 P.GW80.400.26.KW.jpg 14 15 CAT_P.GW80.400.26.KW_2D.gif 17 16 10 | |||||||||

| P.GW100.400.26.KW | GW100 2.6 3ph 400V with CW+CH 12B z18 | 1000 / 800 | 2,6 / 3,1 | 242 | 159 | 0,75 / 0,90 | 2,2 / 2,2 | 3,8 / 3,8 | 38 |

2 P.GW100.400.26.KW 11 GW100 2.6 3ph 400V with CW+CH 12B z18 12 13 P.GW150S.400.40.KW.jpg 14 15 CAT_P.GW100.400.26.KW_2D.gif 17 16 10 |

Rack box

| Article | Description | F [N] | T [Nm] | i [-] | L [mm] | S [mm] | s [mm/rev] | n [rev] | m [kg] |

| P.THG55RK.1.S0750 | THG55RK, L1260 S0750mm | 11000 | 65,00 | 3,125 | 1260 | 750 | 36,19 | 21 | 9,2 |

2 P.THG55RK.1.S0750 11 THG55RK, L1260 S0750mm 12 13 P.THG55RK.1.S0000 - dicht.jpg 14 15 CAT_P.THG55RK.1.S0000_2D.gif 16 17 10 | |||||||||

| P.THG55RK.1.S0900 | THG55RK, L1410 S0900mm | 11000 | 65,00 | 3,125 | 1410 | 900 | 36,19 | 25 | 9,8 |

2 P.THG55RK.1.S0900 11 THG55RK, L1410 S0900mm 12 13 P.THG55RK.1.S0000 - dicht.jpg 14 15 CAT_P.THG55RK.1.S0000_2D.gif 16 17 10 | |||||||||

| P.THG55RK.1.S1100 | THG55RK, L1610 S1100mm | 11000 | 65,00 | 3,125 | 1610 | 1100 | 36,19 | 31 | 10,7 |

2 P.THG55RK.1.S1100 11 THG55RK, L1610 S1100mm 12 13 P.THG55RK.1.S0000 - dicht.jpg 14 15 CAT_P.THG55RK.1.S0000_2D.gif 16 17 10 |

Clamping set

| Article | Description | L [mm] | B [mm] | m [kg] |

| P.THG55RK.SET.2.100.050 | THG55/76RK clamp set column 100x50 mm | 100 | 50 | 1,2 |

2 P.THG55RK.SET.2.100.050 11 THG55/76RK clamp set column 100x50 mm 12 10 P.THG55RK.SET.2.000.00 - dicht.jpg | ||||

| P.THG55RK.SET.2.100.060 | THG55/76RK clamp set column 100x60 mm | 100 | 60 | 0,8 |

2 P.THG55RK.SET.2.100.060 11 THG55/76RK clamp set column 100x60 mm 12 10 P.THG55RK.SET.2.000.00 - dicht.jpg | ||||

| P.THG55RK.SET.2.120.050 | THG55/76RK clamp set column 120x50 mm | 120 | 50 | 1,2 |

2 P.THG55RK.SET.2.120.050 11 THG55/76RK clamp set column 120x50 mm 12 10 P.THG55RK.SET.2.000.00 - dicht.jpg | ||||

| P.THG55RK.SET.2.120.060 | THG55/76RK clamp set column 120x60 mm | 120 | 60 | 0,9 |

2 P.THG55RK.SET.2.120.060 11 THG55/76RK clamp set column 120x60 mm 12 10 P.THG55RK.SET.2.000.00 - dicht.jpg | ||||

| P.THG55RK.SET.2.140.060 | THG55/76RK clamp set column 140x60 mm | 140 | 60 | 1,0 |

2 P.THG55RK.SET.2.140.060 11 THG55/76RK clamp set column 140x60 mm 12 10 P.THG55RK.SET.2.000.00 - dicht.jpg | ||||

| P.THG55RK.SET.2.160.060 | THG55/76RK clamp set column 160x60 mm | 160 | 60 | 1,0 |

2 P.THG55RK.SET.2.160.060 11 THG55/76RK clamp set column 160x60 mm 12 10 P.THG55RK.SET.2.000.00 - dicht.jpg |

Coupling set

| Article | Description | D [mm] | B [mm] | m [kg] |

| P.SKP.D27 | Coupling set D27 for THG25/42/55 rack | 27 | 15 / 20 | 0,2 |

| P.SKP.D32 | Coupling set D32 for THG25/42/55 rack | 32 | 15 / 20 | 0,2 |

Coupling set fastener

| Article | Description | B [mm] | m [kg] |

| P.SKP.BVM.20 | BVM coupling set - THG42/55 rack | 35 | 0,03 |

Locking

| Article | Description | m [kg] |

| P.ABR.24 | Shaft locking ring 24 DIN6799 EZ | 0,01 |

Weld sprockets

| Article | Description | Chain | Shaft | Tmax [Nm] | Db [mm] | D [mm] | L [mm] | m [kg] |

| P.LKWL10B.Z16.D125 | Weld sprocket 10B z16 - 5/4" | 10B z16 | D125 | 420 | 43 | 96 | 30 | 0,4 |

2 P.LKWL10B.Z16.D125 11 Weld sprocket 10B z16 - 5/4" 12 13 P.LKWL10B.Z16.D125.jpg 15 16 CAT_P.LKWL10B.Z16.D125_2D.gif 17 10 |

Chains

| Article | Description | Tmax [Nm] | D [mm] | m [kg] |

| P.KTG10B-2.Z16 | Chain 10B z16 | 420 | 96 | 0,5 |

| P.KTG12B-2.Z18 | Chain 12B z18 | 760 | 126 | 0,8 |

Sprockets on THG55RK

| Article | Description | Chain | Shaft | Tmax [Nm] | D2 [mm] | L [mm] | m [kg] |

| P.KWL10B.Z16.ZK | Sleeve sprocket 10B z16 - ZK | 10B z16 | ZK | 420 | 96 | 30 | 0,6 |

2 P.KWL10B.Z16.ZK 11 Sleeve sprocket 10B z16 - ZK 12 13 P.KWL10B.Z16.ZK.jpg 14 15 CAT_P.KWL10B.Z16.ZK_2D.gif 10 |

Sleeve joint coupling prefab

| Article | Description | Db [mm] | Type | m [kg] |

| P.SLKP125.ZK | Prefab sleeve joint coupling 5/4" - ZK | 42,4 | ZK | 0,2 |

Clamping mounting plates

| Article | Description | H [mm] | B [mm] | A [mm] | L [mm] | m [kg] |

| P.MP.RK.KL.350.25 | Clamping mounting pl. RK 350 truss 25 | 350 | 25 | 205 | 581 | 4,0 |

2 P.MP.RK.KL.350.25 11 Clamping mounting pl. RK 350 truss 25 12 13 P.MP.RK.KL.400.30.jpg 14 10 CAT_P.MP.RK.KL.000.00_2D.gif | ||||||

| P.MP.RK.KL.400.25 | Clamping mounting pl. RK 350 truss 25 | 400 | 25 | 205 | 631 | 5,1 |

2 P.MP.RK.KL.400.25 11 Clamping mounting pl. RK 350 truss 25 12 13 P.MP.RK.KL.400.30.jpg 14 10 CAT_P.MP.RK.KL.000.00_2D.gif | ||||||

| P.MP.RK.KL.400.30 | Clamping mounting pl. RK 400 truss 30 | 400 | 30 | 205 | 631 | 5,1 |

2 P.MP.RK.KL.400.30 11 Clamping mounting pl. RK 400 truss 30 12 13 P.MP.RK.KL.400.30.jpg 14 10 CAT_P.MP.RK.KL.000.00_2D.gif | ||||||

| P.MP.RK.KL.500.30 | Clamping mounting pl. RK 500 truss 30 | 500 | 30 | 205 | 731 | 5,8 |

2 P.MP.RK.KL.500.30 11 Clamping mounting pl. RK 500 truss 30 12 13 P.MP.RK.KL.400.30.jpg 14 10 CAT_P.MP.RK.KL.000.00_2D.gif | ||||||

| P.MP.RK.KL.600.30 | Clamping mounting pl. RK 600 truss 30 | 600 | 30 | 205 | 831 | 6,5 |

2 P.MP.RK.KL.600.30 11 Clamping mounting pl. RK 600 truss 30 12 13 P.MP.RK.KL.400.30.jpg 14 10 CAT_P.MP.RK.KL.000.00_2D.gif |

Multiple options available upon request

Drive systems for ventilation

Rapidly varying weather conditions are the order of the day. The need for good, accurate ventilation systems and airtightness in larger production greenhouses is becoming increasingly important. New cultivation requires insights for less, accurate and metered ventilation in combination with more screens with the aim of keeping as much heat and moisture as possible in the greenhouse to save energy. To achieve an optimal climate through optimal ventilation, our drives are essential for optimal results.

End-wall ventilation in combination with RK - P.THG55RKGC

We are happy to help you with making a calculation

Get in contact with usEndwall truss-rail ventilation systems are used for extra ventilation in the endwall section. With the RKGC system, the rack boxes are placed close to the gutter and fixed on a C-profile between the gutters. These gear racks move one row of end-wall ventilation windows in a section. The gear racks are driven by a GW motor gearbox via drive tubes with chain couplings for the necessary angle correction. - Better climate in the endwall sectons.

- Better climate in the head compartments.

- Ideal installation location gives minimal shading.

- Very easy installation on standard C-profile.

- Suitable for 5/4" prefabricated drive shafts.

- Highly suitable for medium load in combination with THG55RK.

Rack box

| Article | Description | F [N] | T [Nm] | i [-] | L [mm] | S [mm] | s [mm/rev] | n [rev] | m [kg] |

| P.THG55RKGC.1.S0750 | THG55RKGC, L1260 S0750mm | 11000 | 65,00 | 3,125 | 1260 | 750 | 36,19 | 21 | 10,1 |

2 P.THG55RKGC.1.S0750 11 THG55RKGC, L1260 S0750mm 12 13 P.THG55RKGC.1.S0000.jpg 14 15 CAT_P.THG55RKGC.1.S0000_2D.gif 16 17 10 | |||||||||

| P.THG55RKGC.1.S0900 | THG55RKGC, L1410 S0900mm | 11000 | 65,00 | 3,125 | 1410 | 900 | 36,19 | 25 | 10,6 |

2 P.THG55RKGC.1.S0900 11 THG55RKGC, L1410 S0900mm 12 13 P.THG55RKGC.1.S0000.jpg 14 15 CAT_P.THG55RKGC.1.S0000_2D.gif 16 17 10 | |||||||||

| P.THG55RKGC.1.S1100 | THG55RKGC, L1610 S1100mm | 11000 | 65,00 | 3,125 | 1610 | 1100 | 36,19 | 31 | 11,6 |

2 P.THG55RKGC.1.S1100 11 THG55RKGC, L1610 S1100mm 12 13 P.THG55RKGC.1.S0000.jpg 14 15 CAT_P.THG55RKGC.1.S0000_2D.gif 16 17 10 |

Coupling set

| Article | Description | D [mm] | B [mm] | m [kg] |

| P.SKP.D27 | Coupling set D27 for THG25/42/55 rack | 27 | 15 / 20 | 0,2 |

| P.SKP.D32 | Coupling set D32 for THG25/42/55 rack | 32 | 15 / 20 | 0,2 |

Coupling set fastener

| Article | Description | B [mm] | m [kg] |

| P.SKP.BVM.20 | BVM coupling set - THG42/55 rack | 35 | 0,03 |

Locking

| Article | Description | m [kg] |

| P.ABR.24 | Shaft locking ring 24 DIN6799 EZ | 0,01 |

Weld sprockets

| Article | Description | Chain | Shaft | Tmax [Nm] | Db [mm] | D [mm] | L [mm] | m [kg] |

| P.LKWL10B.Z16.D125 | Weld sprocket 10B z16 - 5/4" | 10B z16 | D125 | 420 | 43 | 96 | 30 | 0,4 |

2 P.LKWL10B.Z16.D125 11 Weld sprocket 10B z16 - 5/4" 12 13 P.LKWL10B.Z16.D125.jpg 15 16 CAT_P.LKWL10B.Z16.D125_2D.gif 17 10 |

Chains

| Article | Description | Tmax [Nm] | D [mm] | m [kg] |

| P.KTG10B-2.Z16 | Chain 10B z16 | 420 | 96 | 0,5 |

Tube bolt chain coupling on THG55RKGC

| Article | Description | Tmax [Nm] | D2 [mm] | D3 [mm] | L1 [mm] | L3 [mm] | m [kg] |

| P.BBKK10B.ZK.D125 | Tube bolt CC set 10B ZK z16 5/4" | 420 | 43,1 | 96 | 30 | 150 | 1,9 |

2 P.BBKK10B.ZK.D125 13 Tube bolt CC set 10B ZK z16 5/4" 17 18 P.BBKK10B.ZK.D000.jpg 20 21 CAT_P.BBKK10B.D00.D125_2D.gif 10 |

Drive systems for ventilation

Rapidly varying weather conditions are the order of the day. The need for good, accurate ventilation systems and airtightness in larger production greenhouses is becoming increasingly important. New cultivation requires insights for less, accurate and metered ventilation in combination with more screens with the aim of keeping as much heat and moisture as possible in the greenhouse to save energy. To achieve an optimal climate through optimal ventilation, our drives are essential for optimal results.

Truss-rail ventilation column mounting - P.THG76RK

We are happy to help you with making a calculation

Get in contact with usTruss-rail ventilation systems are used for natural ventilation in Venlo greenhouses. With the RK system, the rack boxes are fixed around the column. One gear rack moves a push-pull tube with push rods that operates one row of ventilation windows in a section. The lee- or wind-side ventilation gear racks are coupled with drive tubes and driven by a GW motor gearbox.

- Ideal mounting location gives minimal shading.

- Easy installation around the column.

- Ideal force transfer onto the column.

- Suitable for 5/4" prefabricated drive shafts.

- Highly suitable for heavy load (15,000 N).

GW motor gearbox

| Article | Description | T (50/60Hz) [Nm] | n (50/60Hz) [rpm] | L [mm] | D [mm] | P (50/60Hz) [kW] | I (@ Y) (50/60Hz) [A] | I (@ Δ) (50/60Hz) [A] | m [kg] |

| P.GW10.3.400.26.KW | GW10 2.6 3ph 400V with CW+CH 10B z16 | 100 / 80 | 2,6 / 3,1 | 168 | 124 | 0,09 / 0,11 | 0,4 / 0,4 | 0,7 / 0,7 | 21 |

2 P.GW10.3.400.26.KW 11 GW10 2.6 3ph 400V with CW+CH 10B z16 12 13 P.GW10.400.26.KW.jpg 14 15 CAT_P.GW10.400.26.KW_2D.gif 17 16 10 | |||||||||

| P.GW10.3.400.52.KW | GW10 5.2 3ph 400V with CW+CH 10B z16 | 100 / 80 | 5,2 / 6,2 | 191 | 124 | 0,18 / 0,22 | 0,7 / 0,7 | 1,2 / 1,2 | 24 |

2 P.GW10.3.400.52.KW 11 GW10 5.2 3ph 400V with CW+CH 10B z16 12 13 P.GW10.400.26.KW.jpg 14 15 CAT_P.GW10.400.26.KW_2D.gif 17 16 10 | |||||||||

| P.GW30.400.26.KW | GW30 2.6 3ph 400V with CW+CH 10B z16 | 300 / 240 | 2,6 / 3,1 | 220 | 145 | 0,25 / 0,30 | 0,8 / 0,8 | 1,4 / 1,4 | 24 |

2 P.GW30.400.26.KW 11 GW30 2.6 3ph 400V with CW+CH 10B z16 12 13 P.GW30.400.26.KW.jpg 14 15 CAT_P.GW30.400.26.KW_2D.gif 17 16 10 | |||||||||

| P.GW30.400.52.KW | GW30 5.2 3ph 400V with CW+CH 10B z16 | 300 / 240 | 5,2 / 6,2 | 220 | 145 | 0,37 / 0,44 | 1,2 / 1,2 | 2,1 / 2,1 | 27 |

2 P.GW30.400.52.KW 11 GW30 5.2 3ph 400V with CW+CH 10B z16 12 13 P.GW30.400.26.KW.jpg 14 15 CAT_P.GW30.400.26.KW_2D.gif 17 16 10 | |||||||||

| P.GW40.400.26.KW | GW40 2.6 3ph 400V with CW+CH 10B z16 | 400 / 320 | 2,6 / 3,1 | 220 | 159 | 0,37 / 0,44 | 1,0 / 1,0 | 1,7 / 1,7 | 29 |

2 P.GW40.400.26.KW 11 GW40 2.6 3ph 400V with CW+CH 10B z16 12 13 P.GW80.400.26.KW.jpg 14 15 CAT_P.GW80.400.26.KW_2D.gif 17 16 10 | |||||||||

| P.GW40.3.400.52.KW | GW40 5.2 3ph 400V with CW+CH 10B z16 | 400 / 320 | 5,2 / 6,2 | 220 | 137 | 0,55 / 0,66 | 1,5 / 1,5 | 2,6 / 2,6 | 29 |

2 P.GW40.3.400.52.KW 11 GW40 5.2 3ph 400V with CW+CH 10B z16 12 13 P.GW80.400.26.KW.jpg 14 15 CAT_P.GW80.400.26.KW_2D.gif 17 16 10 | |||||||||

| P.GW80.400.26.KW | GW80 2.6 3ph 400V with CW+CH 10B z16 | 800 / 640 | 2,6 / 3,1 | 218 | 159 | 0,55 / 0,66 | 1,5 / 1,5 | 2,6 / 2,6 | 31 |

2 P.GW80.400.26.KW 11 GW80 2.6 3ph 400V with CW+CH 10B z16 12 13 P.GW80.400.26.KW.jpg 14 15 CAT_P.GW80.400.26.KW_2D.gif 17 16 10 | |||||||||

| P.GW80.2.400.40.KW | GW80 4.0 3ph 400V with CW+CH 10B z16 d25 | 800 / 640 | 4,0 / 4,8 | 242 | 159 | 0,75 / 0,90 | 2,0 / 2,0 | 3,5 / 3,5 | 38 |

2 P.GW80.2.400.40.KW 11 GW80 4.0 3ph 400V with CW+CH 10B z16 d25 12 13 P.GW80.400.26.KW.jpg 14 15 CAT_P.GW80.400.26.KW_2D.gif 17 16 10 | |||||||||

| P.GW100.400.26.KW | GW100 2.6 3ph 400V with CW+CH 12B z18 | 1000 / 800 | 2,6 / 3,1 | 242 | 159 | 0,75 / 0,90 | 2,2 / 2,2 | 3,8 / 3,8 | 38 |

2 P.GW100.400.26.KW 11 GW100 2.6 3ph 400V with CW+CH 12B z18 12 13 P.GW150S.400.40.KW.jpg 14 15 CAT_P.GW100.400.26.KW_2D.gif 17 16 10 |

Rack box

| Article | Description | F [N] | T [Nm] | i [-] | L [mm] | S [mm] | s [mm/rev] | n [rev] | m [kg] |

| P.THG76RK.1.S0750 | THG76RK 15kN m4, L1250 S0750mm | 15000 | 60,50 | 6,000 | 1250 | 750 | 23 | 33 | 12,9 |

2 P.THG76RK.1.S0750 11 THG76RK 15kN m4, L1250 S0750mm 12 13 P.THG76RK.1.S0000 - dicht.jpg 14 15 CAT_P.THG76RK.1.S0000_2D.gif 16 17 10 | |||||||||

| P.THG76RK.1.S0900 | THG76RK 15kN m4, L1400 S0900mm | 15000 | 60,50 | 6,000 | 1400 | 900 | 23 | 39 | 13,6 |

2 P.THG76RK.1.S0900 11 THG76RK 15kN m4, L1400 S0900mm 12 13 P.THG76RK.1.S0000 - dicht.jpg 14 15 CAT_P.THG76RK.1.S0000_2D.gif 16 17 10 | |||||||||

| P.THG76RK.1.S1050 | THG76RK 15kN m4, L1550 S1050mm | 15000 | 60,50 | 6,000 | 1550 | 1050 | 23 | 48 | 14,4 |

2 P.THG76RK.1.S1050 11 THG76RK 15kN m4, L1550 S1050mm 12 13 P.THG76RK.1.S0000 - dicht.jpg 14 15 CAT_P.THG76RK.1.S0000_2D.gif 16 17 10 |

Clamping set

| Article | Description | L [mm] | B [mm] | m [kg] |

| P.THG55RK.SET.2.100.050 | THG55/76RK clamp set column 100x50 mm | 100 | 50 | 1,2 |

2 P.THG55RK.SET.2.100.050 11 THG55/76RK clamp set column 100x50 mm 12 10 P.THG55RK.SET.2.000.00 - dicht.jpg | ||||

| P.THG55RK.SET.3.100.60 | THG55/76 RK Clamp. set column 100x060 n.B | 100 | 60 | 0,8 |

2 P.THG55RK.SET.3.100.60 11 THG55/76 RK Clamp. set column 100x060 n.B 12 10 P.THG55RK.SET.3.000.00.jpg | ||||

| P.THG55RK.SET.2.120.050 | THG55/76RK clamp set column 120x50 mm | 120 | 50 | 1,2 |

2 P.THG55RK.SET.2.120.050 11 THG55/76RK clamp set column 120x50 mm 12 10 P.THG55RK.SET.2.000.00 - dicht.jpg | ||||

| P.THG55RK.SET.2.120.060 | THG55/76RK clamp set column 120x60 mm | 120 | 60 | 0,9 |

2 P.THG55RK.SET.2.120.060 11 THG55/76RK clamp set column 120x60 mm 12 10 P.THG55RK.SET.2.000.00 - dicht.jpg | ||||

| P.THG55RK.SET.2.140.060 | THG55/76RK clamp set column 140x60 mm | 140 | 60 | 1,0 |

2 P.THG55RK.SET.2.140.060 11 THG55/76RK clamp set column 140x60 mm 12 10 P.THG55RK.SET.2.000.00 - dicht.jpg |

Coupling set

| Article | Description | D [mm] | B [mm] | m [kg] |

| P.SKP.D32.B25 | Coupling set D32 for THG76 rack | 32 | 25 | 0,2 |

Coupling set fastener

| Article | Description | B [mm] | m [kg] |

| P.SKP.BVM.25 | BVM coupling set - THG76 rack | 40 | 0,03 |

Locking

| Article | Description | m [kg] |

| P.ABR.24 | Shaft locking ring 24 DIN6799 EZ | 0,01 |

Weld sprockets

| Article | Description | Chain | Shaft | Tmax [Nm] | Db [mm] | D [mm] | L [mm] | m [kg] |

| P.LKWL10B.Z16.D125 | Weld sprocket 10B z16 - 5/4" | 10B z16 | D125 | 420 | 43 | 96 | 30 | 0,4 |

2 P.LKWL10B.Z16.D125 11 Weld sprocket 10B z16 - 5/4" 12 13 P.LKWL10B.Z16.D125.jpg 15 16 CAT_P.LKWL10B.Z16.D125_2D.gif 17 10 |

Chains

| Article | Description | Tmax [Nm] | D [mm] | m [kg] |

| P.KTG10B-2.Z16 | Chain 10B z16 | 420 | 96 | 0,5 |

| P.KTG12B-2.Z18 | Chain 12B z18 | 760 | 126 | 0,8 |

Sleeve sprockets on THG76RK

| Article | Description | Chain | Shaft | Tmax [Nm] | D [mm] | L [mm] | m [kg] |

| P.KWL10B.Z16.ZK | Sleeve sprocket 10B z16 - ZK | 10B z16 | ZK | 420 | 96 | 30 | 0,6 |

2 P.KWL10B.Z16.ZK 11 Sleeve sprocket 10B z16 - ZK 12 13 P.KWL10B.Z16.ZK.jpg 14 15 CAT_P.KWL10B.Z16.ZK_2D.gif 10 |

Sleeve joint coupling prefab

| Article | Description | Db [mm] | Type | m [kg] |

| P.SLKP125.ZK | Prefab sleeve joint coupling 5/4" - ZK | 42,4 | ZK | 0,2 |

Clamping mounting plates RK

| Article | Description | H [mm] | B [mm] | A [mm] | L [mm] | m [kg] |

| P.MP.RK.KL.350.25 | Clamping mounting pl. RK 350 truss 25 | 350 | 25 | 205 | 581 | 4,0 |

2 P.MP.RK.KL.350.25 11 Clamping mounting pl. RK 350 truss 25 12 13 P.MP.RK.KL.400.30.jpg 14 10 CAT_P.MP.RK.KL.000.00_2D.gif | ||||||

| P.MP.RK.KL.400.25 | Clamping mounting pl. RK 350 truss 25 | 400 | 25 | 205 | 631 | 5,1 |

2 P.MP.RK.KL.400.25 11 Clamping mounting pl. RK 350 truss 25 12 13 P.MP.RK.KL.400.30.jpg 14 10 CAT_P.MP.RK.KL.000.00_2D.gif | ||||||

| P.MP.RK.KL.400.30 | Clamping mounting pl. RK 400 truss 30 | 400 | 30 | 205 | 631 | 5,1 |

2 P.MP.RK.KL.400.30 11 Clamping mounting pl. RK 400 truss 30 12 13 P.MP.RK.KL.400.30.jpg 14 10 CAT_P.MP.RK.KL.000.00_2D.gif | ||||||

| P.MP.RK.KL.500.30 | Clamping mounting pl. RK 500 truss 30 | 500 | 30 | 205 | 731 | 5,8 |

2 P.MP.RK.KL.500.30 11 Clamping mounting pl. RK 500 truss 30 12 13 P.MP.RK.KL.400.30.jpg 14 10 CAT_P.MP.RK.KL.000.00_2D.gif | ||||||

| P.MP.RK.KL.600.30 | Clamping mounting pl. RK 600 truss 30 | 600 | 30 | 205 | 831 | 6,5 |

2 P.MP.RK.KL.600.30 11 Clamping mounting pl. RK 600 truss 30 12 13 P.MP.RK.KL.400.30.jpg 14 10 CAT_P.MP.RK.KL.000.00_2D.gif |

Multiple options available upon request

Drive systems for ventilation

Rapidly varying weather conditions are the order of the day. The need for good, accurate ventilation systems and airtightness in larger production greenhouses is becoming increasingly important. New cultivation requires insights for less, accurate and metered ventilation in combination with more screens with the aim of keeping as much heat and moisture as possible in the greenhouse to save energy. To achieve an optimal climate through optimal ventilation, our drives are essential for optimal results.

End-wall ventilation in combination with RK - P.THG76RKGC

We are happy to help you with making a calculation

Get in contact with usEndwall truss-rail ventilation systems are used for extra ventilation in the endwall section. With the RKGC system, the rack boxes are placed close to the gutter and fixed on a C-profile between the gutters. These gear racks move one row of endwall ventilation windows in a section. The gear racks are driven by a GW motor gearbox via drive tubes equipped with chain couplings for the necessary angle correction . - Better climate in the endwall sections.

- Better climate in the head compartments.

- Ideal installation location gives minimal shading.

- Very easy installation on standard C-profile.

- Suitable for 5/4" prefabricated drive shafts.

- Highly suitable for heavy load in combination with THG76RK.

Rack box

| Article | Description | F [N] | T [Nm] | i [-] | L [mm] | S [mm] | s [mm/rev] | n [rev] | m [kg] |

| P.THG76RKGC.1.S0750 | THG76RKGC 15kN m4, L1250 S0750mm | 15000 | 60,50 | 6,000 | 1250 | 750 | 23 | 33 | 14,1 |

2 P.THG76RKGC.1.S0750 11 THG76RKGC 15kN m4, L1250 S0750mm 12 13 P.THG76RKGC.1.S0000.jpg 14 15 CAT_P.THG76RKGC.1.S0000_2D.gif 16 17 10 | |||||||||

| P.THG76RKGC.1.S0900 | THG76RKGC 15kN m4, L1400 S0900mm | 15000 | 60,50 | 6,000 | 1400 | 900 | 23 | 39 | 14,9 |

2 P.THG76RKGC.1.S0900 11 THG76RKGC 15kN m4, L1400 S0900mm 12 13 P.THG76RKGC.1.S0000.jpg 14 15 CAT_P.THG76RKGC.1.S0000_2D.gif 16 17 10 | |||||||||

| P.THG76RKGC.1.S1050 | THG76RKGC 15kN m4, L1550 S1050mm | 15000 | 60,50 | 6,000 | 1550 | 1050 | 23 | 48 | 15,9 |

2 P.THG76RKGC.1.S1050 11 THG76RKGC 15kN m4, L1550 S1050mm 12 13 P.THG76RKGC.1.S0000.jpg 14 15 CAT_P.THG76RKGC.1.S0000_2D.gif 16 17 10 |

Coupling set

| Article | Description | D [mm] | B [mm] | m [kg] |

| P.SKP.D32.B25 | Coupling set D32 for THG76 rack | 32 | 25 | 0,2 |

Coupling set fastener

| Article | Description | B [mm] | m [kg] |

| P.SKP.BVM.25 | BVM coupling set - THG76 rack | 40 | 0,03 |

Locking

| Article | Description | m [kg] |

| P.ABR.24 | Shaft locking ring 24 DIN6799 EZ | 0,01 |

Weld sprockets

| Article | Description | Chain | Shaft | Tmax [Nm] | Db [mm] | D [mm] | L [mm] | m [kg] |

| P.LKWL10B.Z16.D125 | Weld sprocket 10B z16 - 5/4" | 10B z16 | D125 | 420 | 43 | 96 | 30 | 0,4 |

2 P.LKWL10B.Z16.D125 11 Weld sprocket 10B z16 - 5/4" 12 13 P.LKWL10B.Z16.D125.jpg 15 16 CAT_P.LKWL10B.Z16.D125_2D.gif 17 10 |

Chains

| Article | Description | Tmax [Nm] | D [mm] | m [kg] |

| P.KTG10B-2.Z16 | Chain 10B z16 | 420 | 96 | 0,5 |

Tube bolt chain coupling on THG76RKGC

| Article | Description | Tmax [Nm] | D2 [mm] | D3 [mm] | L1 [mm] | L3 [mm] | m [kg] |

| P.BBKK10B.ZK.D125 | Tube bolt CC set 10B ZK z16 5/4" | 420 | 43,1 | 96 | 30 | 150 | 1,9 |

2 P.BBKK10B.ZK.D125 13 Tube bolt CC set 10B ZK z16 5/4" 17 18 P.BBKK10B.ZK.D000.jpg 20 21 CAT_P.BBKK10B.D00.D125_2D.gif 10 |

Drive systems for ventilation

Rapidly varying weather conditions are the order of the day. The need for good, accurate ventilation systems and airtightness in larger production greenhouses is becoming increasingly important. New cultivation requires insights for less, accurate and metered ventilation in combination with more screens with the aim of keeping as much heat and moisture as possible in the greenhouse to save energy. To achieve an optimal climate through optimal ventilation, our drives are essential for optimal results.

De Gier Drive Systems

+ 31 174 29 20 89