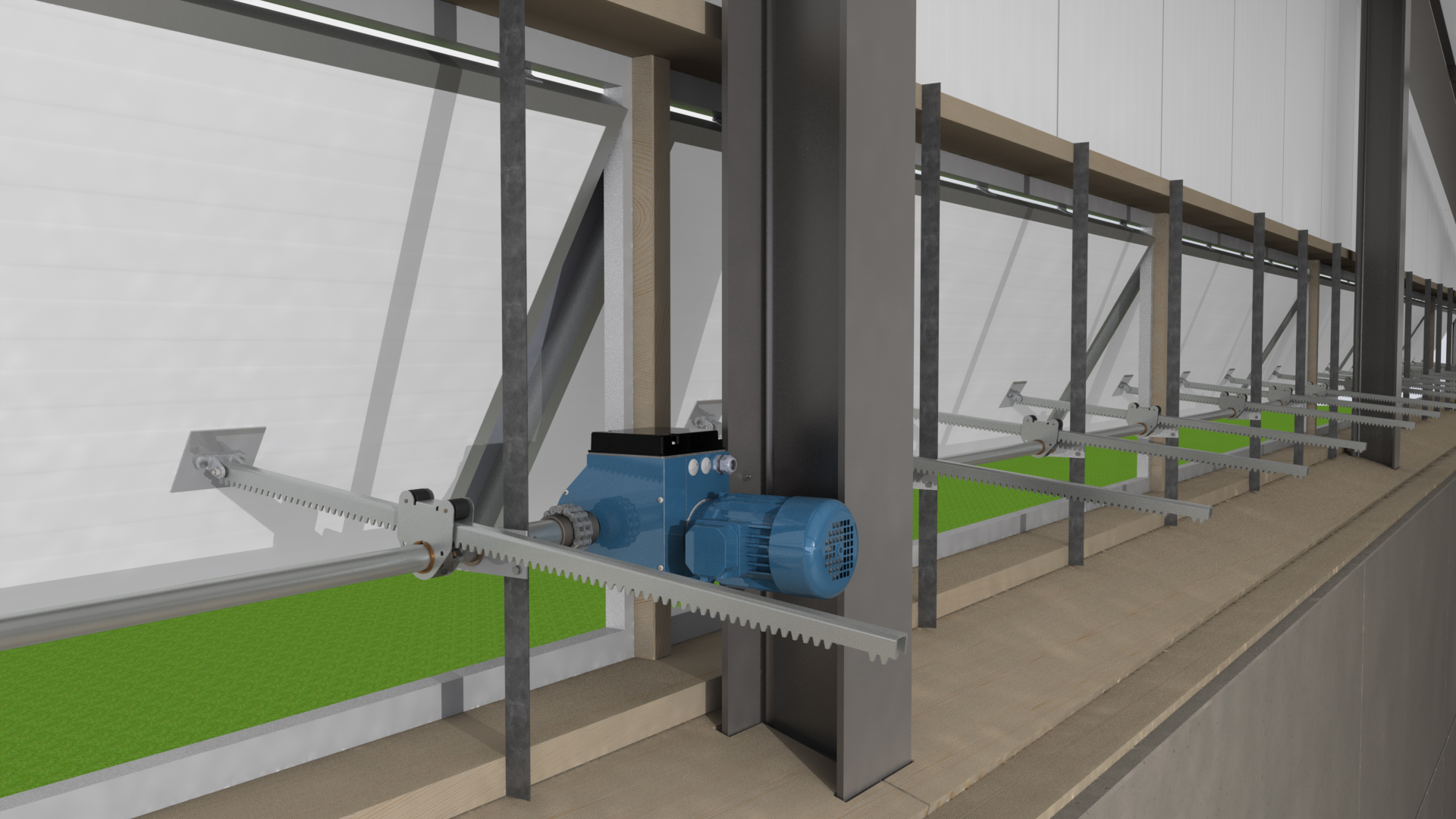

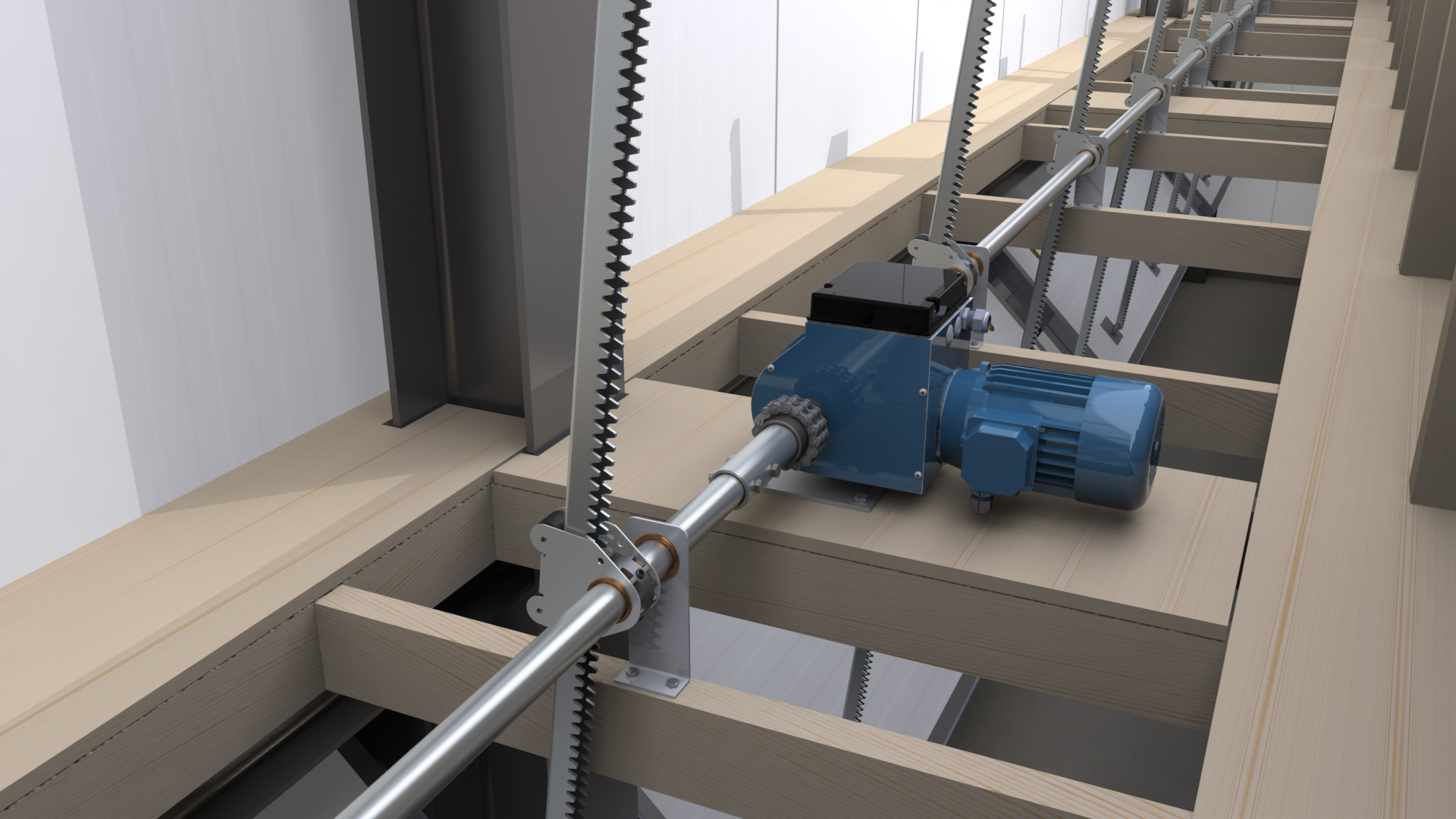

Ventilation - continuous ridge ventilation

We are happy to help you with making a calculation

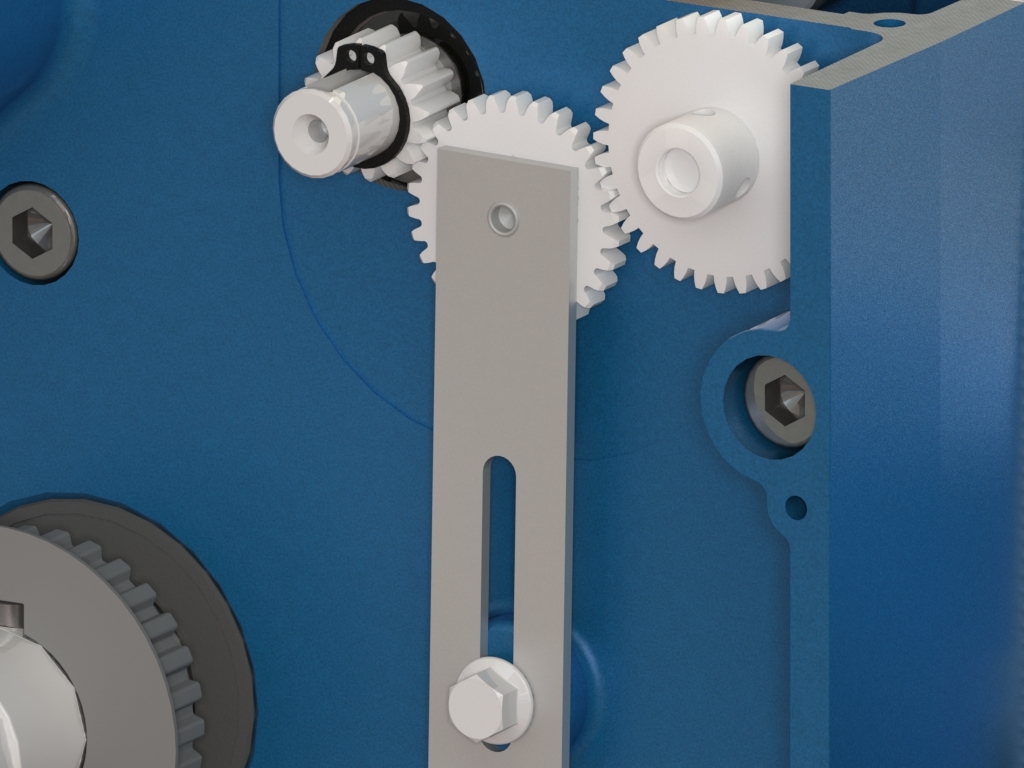

Get in contact with usOne solution for natural ventilation is to use continuous ridge ventilation. The ridge ventilation is opened and closed by a drive in combination with a gear rack system. By using this system, you can create an ideal climate in the building.

- For natural ventilation and daylight in livestock buildings.

- Ideal operation in combination with gear rack system.

- Precise opening and closing of ridge ventilation.

- Low-maintenance and low-noise.

- Cost-effective solution.

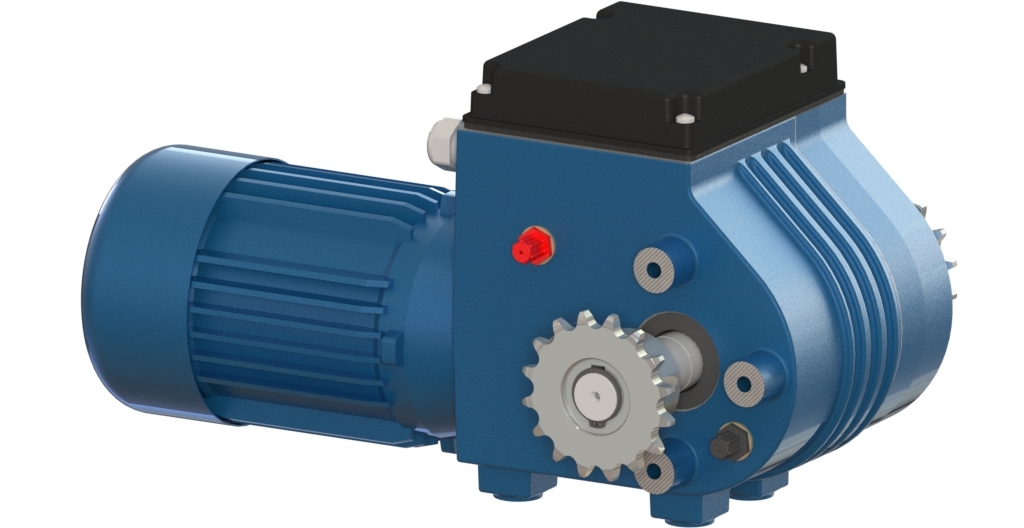

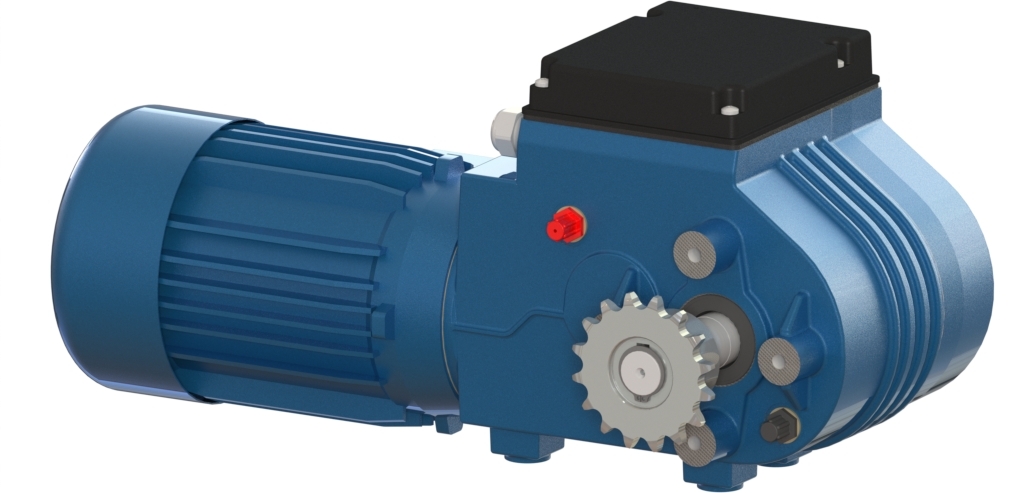

GW motor gearbox

| Article | Description | T (50/60Hz) [Nm] | L [mm] | D [mm] | P (50/60Hz) [kW] | I (@ Δ) (50/60Hz) [A] | I (@ Y) (50/60Hz) [A] | m [kg] |

| P.GW10.3.230.13.KW | GW10 1.3 1ph 230V with CW+CH 10B z16 | 100 / - | 191 | 124 | 0,09 / - | - | 1,1 / - | 21 |

2 P.GW10.3.230.13.KW 11 GW10 1.3 1ph 230V with CW+CH 10B z16 13 14 P.GW10.400.26.KW.jpg 15 16 CAT_P.GW10.400.26.KW_2D.gif 17 10 | ||||||||

| P.GW10.3.230.26.KW | GW10 2.6 1ph 230V with CW+CH 10B z16 | 100 / - | 168 | 124 | 0,09 / - | - | 0,9 / - | 21 |

2 P.GW10.3.230.26.KW 11 GW10 2.6 1ph 230V with CW+CH 10B z16 13 14 P.GW10.400.26.KW.jpg 15 16 CAT_P.GW10.400.26.KW_2D.gif 17 10 | ||||||||

| P.GW10.3.400.13.KW | GW10 1.3 3ph 400V with CW+CH 10B z16 | 100 / 80 | 191 | 124 | 0,09 / 0,11 | 0,9 / 0,9 | 0,5 / 0,5 | 21 |

2 P.GW10.3.400.13.KW 11 GW10 1.3 3ph 400V with CW+CH 10B z16 13 14 P.GW10.400.26.KW.jpg 15 16 CAT_P.GW10.400.26.KW_2D.gif 17 10 | ||||||||

| P.GW10.3.400.26.KW | GW10 2.6 3ph 400V with CW+CH 10B z16 | 100 / 80 | 168 | 124 | 0,09 / 0,11 | 0,7 / 0,7 | 0,4 / 0,4 | 21 |

2 P.GW10.3.400.26.KW 11 GW10 2.6 3ph 400V with CW+CH 10B z16 13 14 P.GW10.400.26.KW.jpg 15 16 CAT_P.GW10.400.26.KW_2D.gif 17 10 | ||||||||

| P.GW30.2.230.13.KW | GW30 1.3 1ph 230V with CW+CH 10B z16 | 300 / - | 220 | 145 | 0,12 / - | - | 1,3 / - | 19 |

2 P.GW30.2.230.13.KW 11 GW30 1.3 1ph 230V with CW+CH 10B z16 13 14 P.GW30.400.26.KW.jpg 15 16 CAT_P.GW30.400.26.KW_2D.gif 17 10 | ||||||||

| P.GW30.2.230.26.KW | GW30 2.6 1ph 230V with CW+CH 10B z16 | 300 / - | 220 | 145 | 0,12 / - | - | 1,3 / - | 21 |

2 P.GW30.2.230.26.KW 11 GW30 2.6 1ph 230V with CW+CH 10B z16 13 14 P.GW30.400.26.KW.jpg 15 16 CAT_P.GW30.400.26.KW_2D.gif 17 10 | ||||||||

| P.GW30.400.13.KW | GW30 1.3 3ph 400V with CW+CH 10B z16 | 300 / 240 | 191 | 145 | 0,18 / 0,22 | 1,2 / 1,2 | 0,7 / 0,7 | 22 |

2 P.GW30.400.13.KW 11 GW30 1.3 3ph 400V with CW+CH 10B z16 13 14 P.GW30.400.26.KW.jpg 15 16 CAT_P.GW30.400.26.KW_2D.gif 17 10 | ||||||||

| P.GW30.400.26.KW | GW30 2.6 3ph 400V with CW+CH 10B z16 | 300 / 240 | 220 | 145 | 0,25 / 0,30 | 1,4 / 1,4 | 0,8 / 0,8 | 24 |

2 P.GW30.400.26.KW 11 GW30 2.6 3ph 400V with CW+CH 10B z16 13 14 P.GW30.400.26.KW.jpg 15 16 CAT_P.GW30.400.26.KW_2D.gif 17 10 | ||||||||

| P.GW40.2.230.13.KW | GW40 1.3 1ph 230V with CW+CH 10B z16 | 400 / - | 220 | 159 | 0,25 / - | - | 3,1 / - | 26 |

2 P.GW40.2.230.13.KW 11 GW40 1.3 1ph 230V with CW+CH 10B z16 13 14 P.GW80.400.26.KW.jpg 15 16 CAT_P.GW80.400.26.KW_2D.gif 17 10 | ||||||||

| P.GW40.2.230.26.KW | GW40 2.6 1ph 230V with CW+CH 10B z16 | 400 / - | 220 | 137 | 0,25 / - | - | 3,2 / - | 29 |

2 P.GW40.2.230.26.KW 11 GW40 2.6 1ph 230V with CW+CH 10B z16 13 14 P.GW80.400.26.KW.jpg 15 16 CAT_P.GW80.400.26.KW_2D.gif 17 10 | ||||||||

| P.GW40.400.13.KW | GW40 1.3 3ph 400V with CW+CH 10B z16 | 400 / 320 | 220 | 159 | 0,25 / 0,30 | 1,4 / 1,4 | 0,8 / 0,8 | 27 |

2 P.GW40.400.13.KW 11 GW40 1.3 3ph 400V with CW+CH 10B z16 13 14 P.GW80.400.26.KW.jpg 15 16 CAT_P.GW80.400.26.KW_2D.gif 17 10 | ||||||||

| P.GW40.400.26.KW | GW40 2.6 3ph 400V with CW+CH 10B z16 | 400 / 320 | 220 | 159 | 0,37 / 0,44 | 1,7 / 1,7 | 1,0 / 1,0 | 29 |

2 P.GW40.400.26.KW 11 GW40 2.6 3ph 400V with CW+CH 10B z16 13 14 P.GW80.400.26.KW.jpg 15 16 CAT_P.GW80.400.26.KW_2D.gif 17 10 |

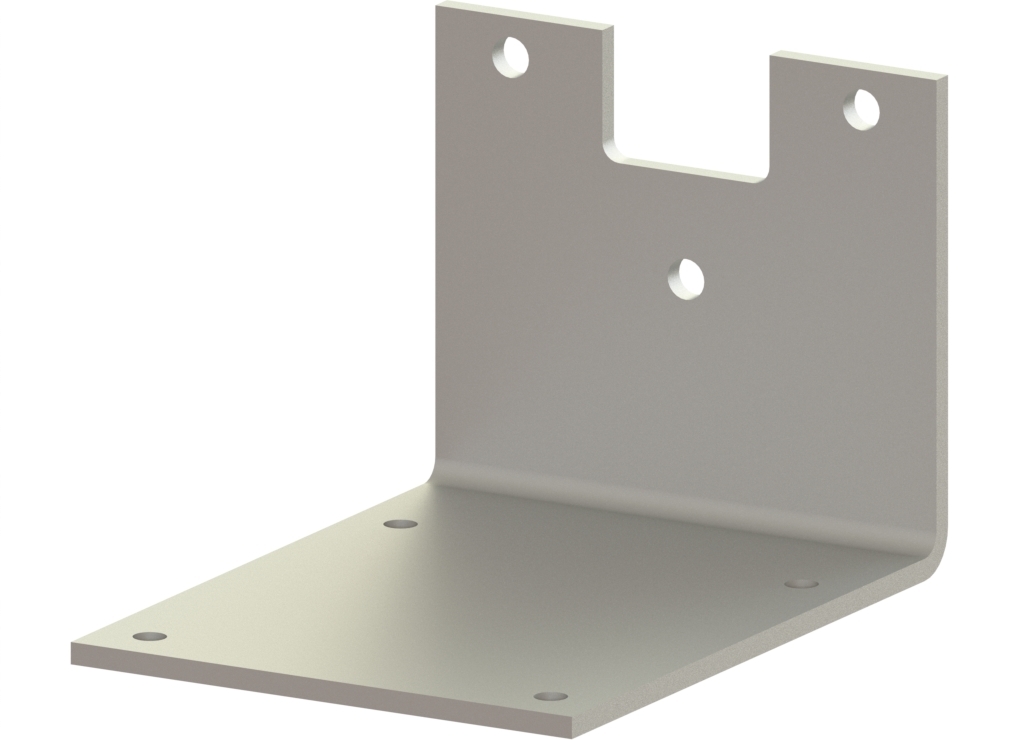

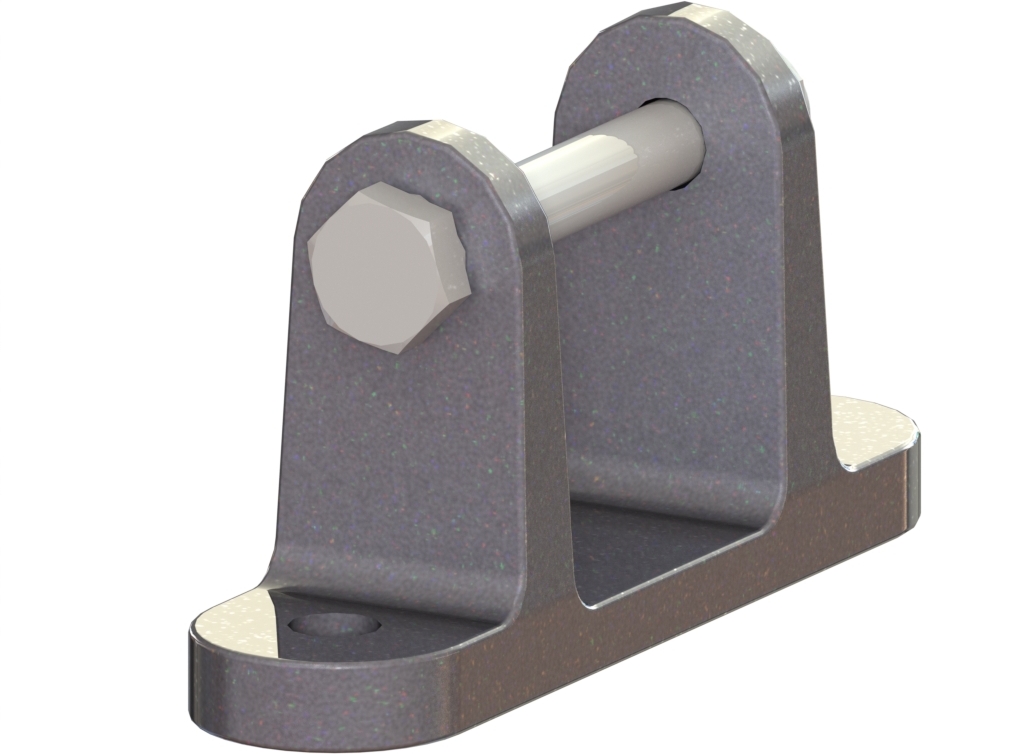

Mounting plate

| Article | Description | A [mm] | H [mm] | m [kg] |

| P.MP.GW.H.A100 | Mounting plate GW right angle A100 H111 | 100 | 111 | 2,0 |

| P.MP.GW.H.A122 | Mounting plate GW right angle A122 H133 | 122 | 133 | 2,2 |

| P.MP.GW.R.A163 | Mounting plate GW straight A163 L174 | 174 | 163 | 1,2 |

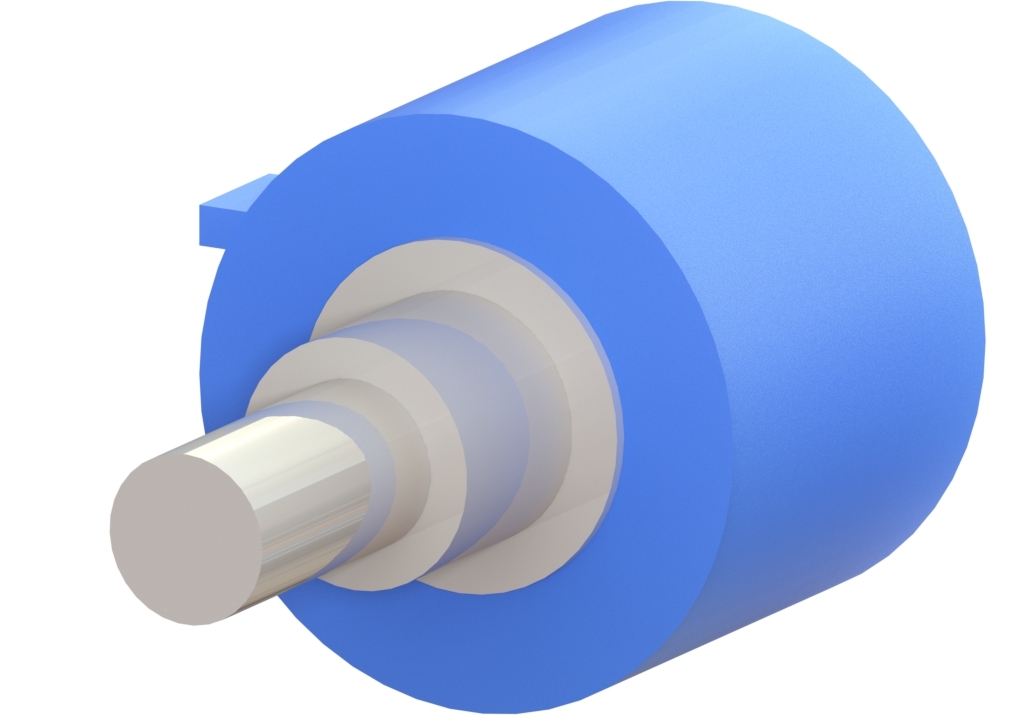

Tube bolt sprocket

| Article | Description | Tmax [Nm] | Db [mm] | D [mm] | L [mm] | m [kg] |

| P.BBKWL10B.Z16.D100 | Tube bolt sprocket 10B z16 - 1" | 420 | 34 | 96 | 150 | 0,8 |

2 P.BBKWL10B.Z16.D100 13 Tube bolt sprocket 10B z16 - 1" 15 16 P.BBKWL10B.Z16.D100.jpg 17 10 CAT_P.BBKWL10B.Z16.D100_2D.gif |

Weld sprocket

| Article | Description | Chain | Shaft | Tmax [Nm] | Db [mm] | D [mm] | L [mm] | m [kg] |

| P.LKWL10B.Z16.D100 | Weld sprocket 10B z16 - 1" and 2" | 10B z16 | D100 | 420 | 34 | 96 | 30 | 0,5 |

2 P.LKWL10B.Z16.D100 11 Weld sprocket 10B z16 - 1" and 2" 12 13 P.LKWL10B.Z16.D100.jpg 15 16 CAT_P.LKWL10B.Z16.D100_2D.gif 17 10 |

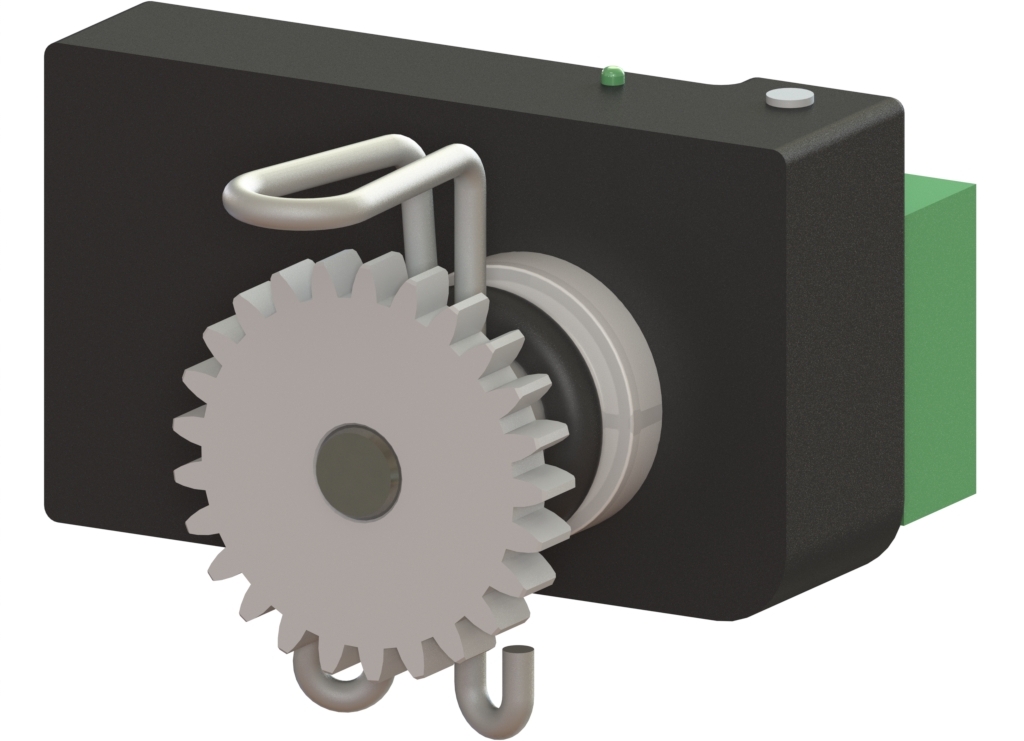

Rack box

| Article | Description | T [Nm] | s [mm/rev] | Usage | m [kg] |

| P.THG30.UNIT.U | THG30 Universal | 10,4 | 138,23 | Intens | 0,43 |

Window bracket

| Article | Article name | m [kg] |

| P.THG30.RB | THG30 aluminium window bracket | 0,06 |

Gear rack

| Article | Description | F [N] | L [mm] | B [mm] | D [mm] | m [kg] |

| P.THG30.3.L1451 | THG30 rack 3 mm L=1451 mm | 450 | 1451 | 25 | 3 | 2,2 |

2 P.THG30.3.L1451 11 THG30 rack 3 mm L=1451 mm 12 13 RAW_P.THG30.0.L0000.jpg 14 10 CAT_P.THG30.3.L0000_2D.gif | ||||||

| P.THG30.3.L1551 | THG30 rack 3 mm L=1551 mm | 450 | 1551 | 25 | 3 | 2,4 |

2 P.THG30.3.L1551 11 THG30 rack 3 mm L=1551 mm 12 13 RAW_P.THG30.0.L0000.jpg 14 10 CAT_P.THG30.3.L0000_2D.gif | ||||||

| P.THG30.3.L1652 | THG30 rack 3 mm L=1652 mm | 450 | 1652 | 25 | 3 | 2,5 |

2 P.THG30.3.L1652 11 THG30 rack 3 mm L=1652 mm 12 13 RAW_P.THG30.0.L0000.jpg 14 10 CAT_P.THG30.3.L0000_2D.gif | ||||||

| P.THG30.3.L1752 | THG30 rack 3 mm L=1752 mm | 450 | 1752 | 25 | 3 | 2,7 |

2 P.THG30.3.L1752 11 THG30 rack 3 mm L=1752 mm 12 13 RAW_P.THG30.0.L0000.jpg 14 10 CAT_P.THG30.3.L0000_2D.gif | ||||||

| P.THG30.3.L1852 | THG30 rack 3 mm L=1852 mm | 450 | 1852 | 25 | 3 | 2,8 |

2 P.THG30.3.L1852 11 THG30 rack 3 mm L=1852 mm 12 13 RAW_P.THG30.0.L0000.jpg 14 10 CAT_P.THG30.3.L0000_2D.gif | ||||||

| P.THG30.3.L2054 | THG30 rack 3 mm L=2054 mm | 450 | 2054 | 25 | 3 | 3,2 |

2 P.THG30.3.L2054 11 THG30 rack 3 mm L=2054 mm 12 13 RAW_P.THG30.0.L0000.jpg 14 10 CAT_P.THG30.3.L0000_2D.gif |

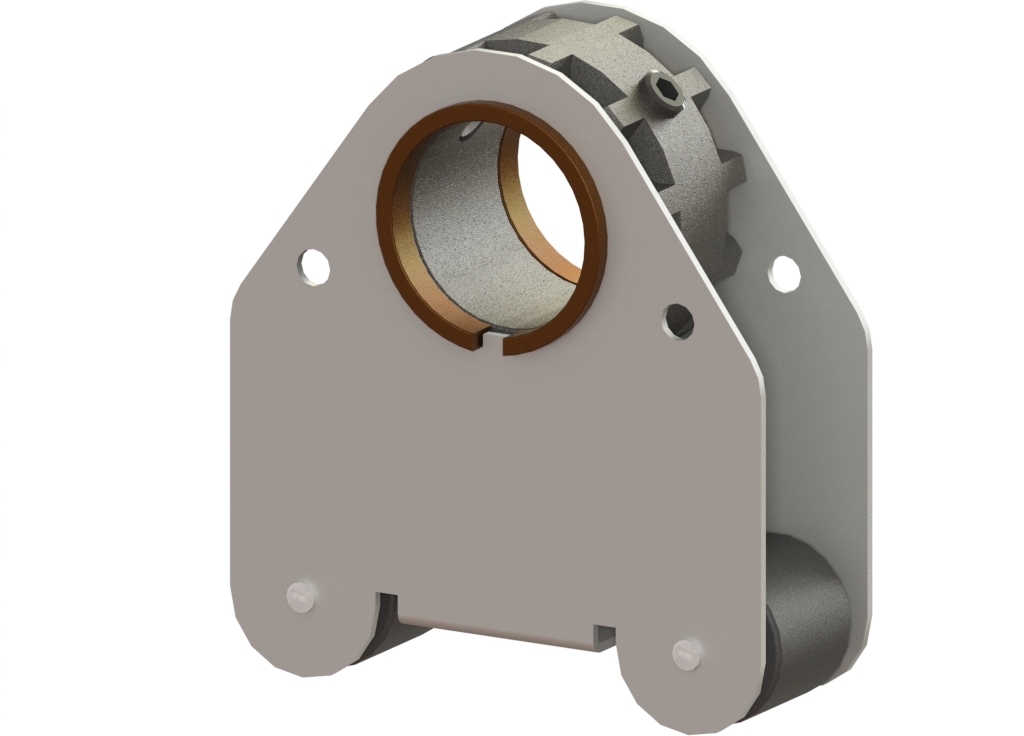

Slide bearing plate

| Article | Description | A [mm] | H [mm] | L [mm] | m [kg] |

| P.GL100.H.L150 | Slide bearing plate 1" H A92 L150 mm | 92 | 125 | 150 | 0,2 |

| P.GL100.H.L158 | Slide bearing plate 1" H A100 L158 mm | 100 | 133 | 158 | 0,2 |

| P.GL100.H.L150 | Slide bearing plate 1" H A92 L150 mm | 92 | 125 | 150 | 0,2 |

| P.GL100.H.L180 | Slide bearing plate 1" H A122 L180 mm | 122 | 155 | 180 | 0,2 |

Encoder I-DE

| Article | Description | n [rpm] | m [kg] |

| P.IDE.024.01 | I-DE 24V AC/DC digital/analogue Enc. built-in | 1,2 - 8,0 | 0,06 |

Potentiometer

| Article | Description | Ohm [ohm] | m [kg] |

| P.PM.500 | Potentiometer 500 ohm built-in | 500 | 0,037 |

| P.PM.1000 | Potentiometer 1000 ohm built-in | 1000 | 0,037 |

| P.PM.5000 | Potentiometer 5000 ohm built-in | 5000 | 0,037 |

| P.PM.10000 | Potentiometer 10 000 ohm built-in | 10000 | 0,037 |

| P.PM.2000 | Potentiometer 2000 ohm built-in | 2000 | 0,037 |

Potentiometer gear set

| Article | Description | i [-] | m [kg] |

| P.PM.TWS.6,58 | Gear set 70.32.30.48 | 6,58 | 0,10 |

| P.PM.TWS.7,20 | Gear set 68.34.30.48 | 7,20 | 0,13 |

| P.PM.TWS.8,16 | Gear set 30.17.30.48 | 8,16 | 0,10 |

| P.PM.TWS.9,60 | Gear set 30.20.30.48 | 9,60 | 0,10 |

| P.PM.TWS.11,04 | Gear set 30.23.30.48 | 11,0 | 0,10 |

| P.PM.TWS.12,48 | Gear set 30.26.30.48 | 12,4 | 0,10 |

| P.PM.TWS.13,92 | Gear set 30.29.30.48 | 13,9 | 0,10 |

Drive systems for ventilation

Crop retention is about much more than simply storage. Ideal air conditions are required at each stage of storage to dry, cool and maintain tubers at temperature. This stops diseases from developing, suppresses germination and maintains quality. Especially for use in storage areas, De Gier offers the perfect drives: in combination with the storage area climate computer, extra precise motion of the drives that control temperature and humidity for a refined and optimal storage climate.

De Gier Drive Systems

+ 31 174 29 20 89