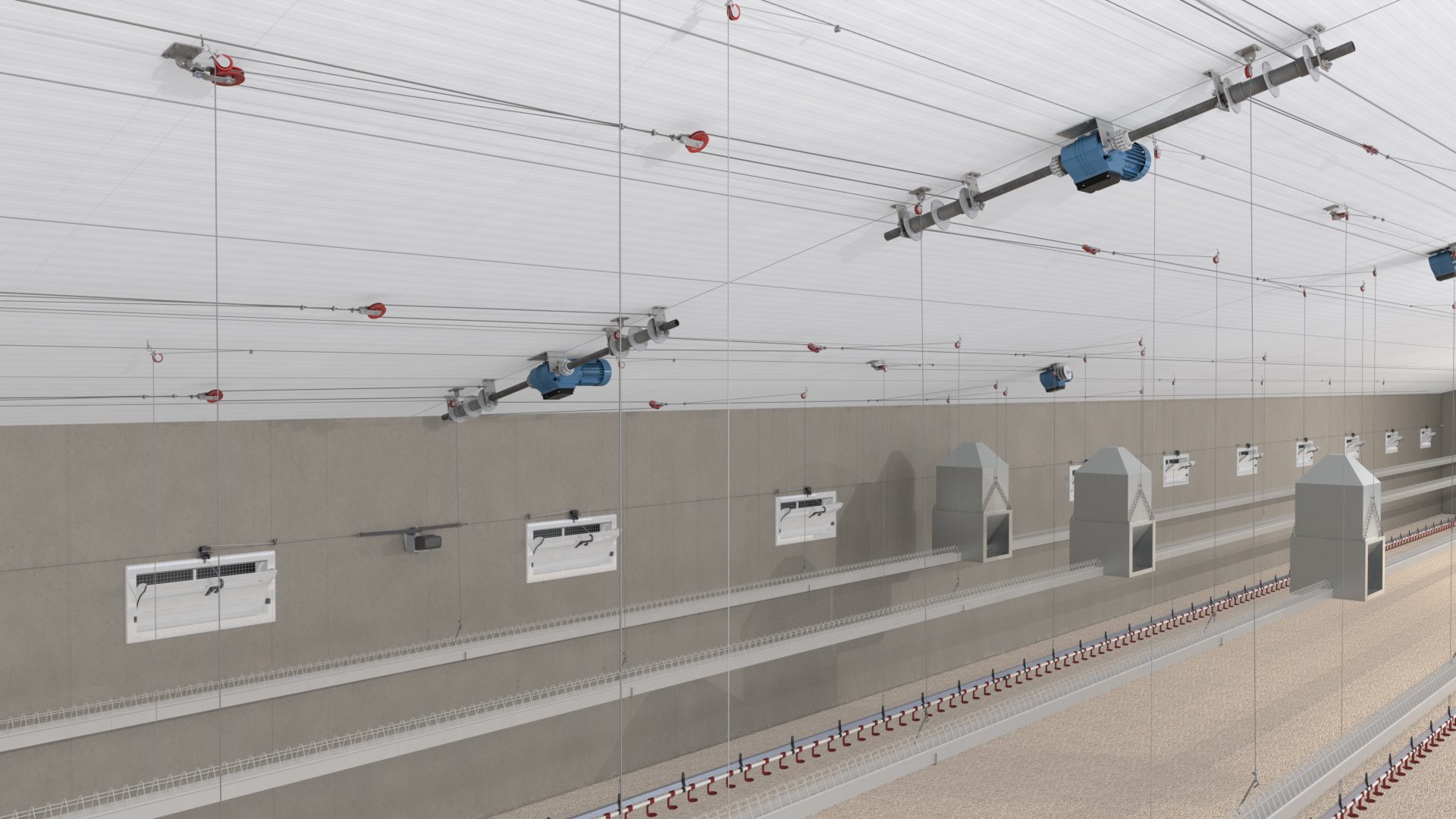

Drag chain system 2 x L2 winch drum 2:1

We are happy to help you with making a calculation

Get in contact with usThe GW winch motor with a double cable winch drum mounted on the roof winches, via a double loop, the drag chain system in a controlled manner and lowers it to the desired height. The double loop solution increases the capacity of the winch system. The 4.0 or 5.2 rpm motor gearboxes ensure perfect control.

- High winch capacity using double pulley system.

- Powerful GW motor gearboxes.

- Wide selection of 1~phase and 3~phase 50/60Hz motors.

- Complete package of couplings, bearing plates and components.

- UL/CSA for United States and Canadian market.

- Precise switching by integrated limit switch.

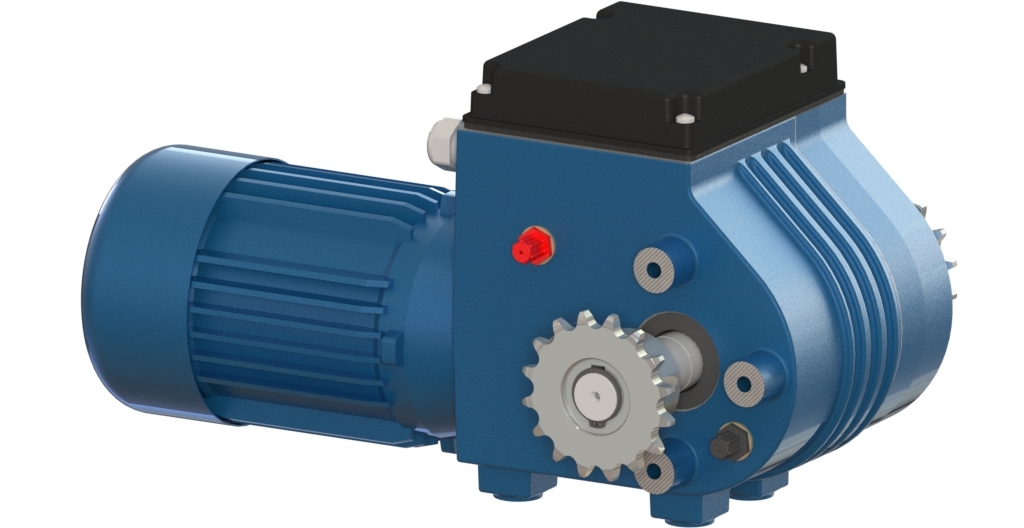

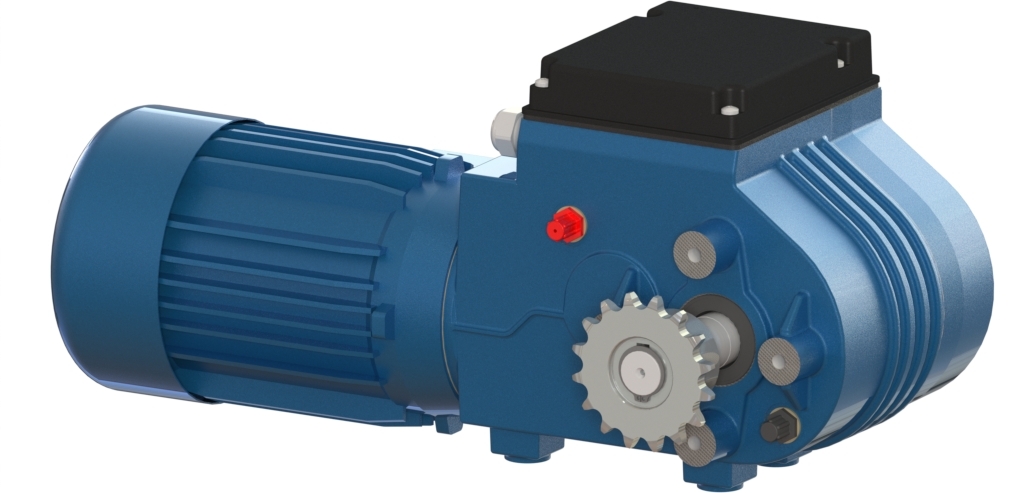

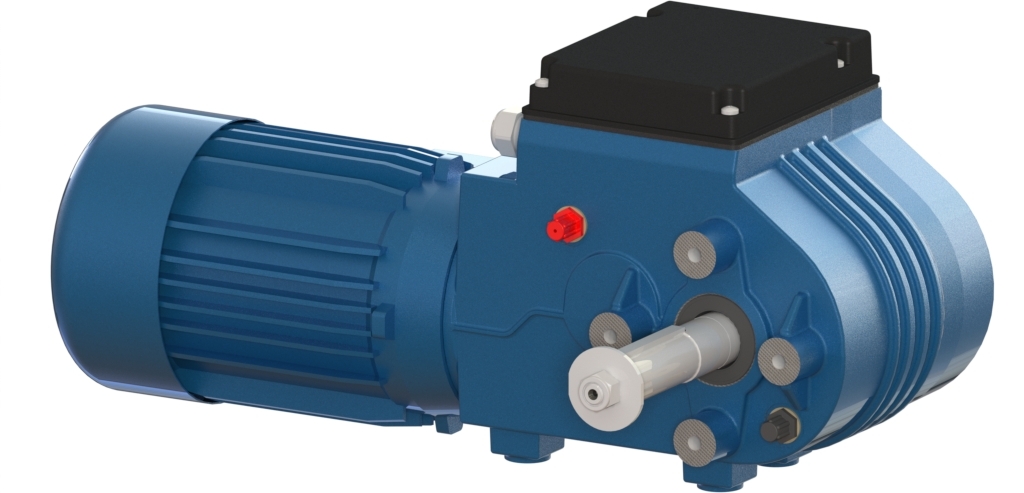

GW motor gearbox

| Article | Description | T (50/60Hz) [Nm] | n (50/60Hz) [rpm] | L [mm] | D [mm] | P (50/60Hz) [kW] | I (@ Y) (50/60Hz) [A] | I (@ Δ) (50/60Hz) [A] | m [kg] |

| P.GW30.400.52.KW | GW30 5.2 3ph 400V with CW+CH 10B z16 | 300 / 240 | 5,2 / 6,2 | 220 | 145 | 0,37 / 0,44 | 1,2 / 1,2 | 2,1 / 2,1 | 27 |

2 P.GW30.400.52.KW 11 GW30 5.2 3ph 400V with CW+CH 10B z16 12 13 P.GW30.400.26.KW.jpg 14 15 CAT_P.GW30.400.26.KW_2D.gif 17 16 10 | |||||||||

| P.GW40HC.400.26.KW | GW40HC 2.6 3ph 400V with CW+CH 10B z16 | 400 / 320 | 2,6 / 3,1 | 220 | 137 | 0,37 / 0,44 | 1,0 / 1,0 | 1,7 / 1,7 | 30 |

2 P.GW40HC.400.26.KW 11 GW40HC 2.6 3ph 400V with CW+CH 10B z16 12 13 P.GW80HB.400.26.KW.jpg 14 15 CAT_P.GW80HB.400.26.KW_2D.gif 17 16 10 | |||||||||

| P.GW80HC.2.400.40.KW | GW80HC 4.0 3ph 400V with CW+CH 10B z16 | 800 / 640 | 4,0 / 4,8 | 242 | 156 | 0,75 / 0,90 | 2,0 / 2,0 | 3,5 / 3,5 | 32 |

2 P.GW80HC.2.400.40.KW 11 GW80HC 4.0 3ph 400V with CW+CH 10B z16 12 13 P.GW80.400.26.KW.jpg 14 15 CAT_P.GW80.400.26.KW_2D.gif 17 16 10 |

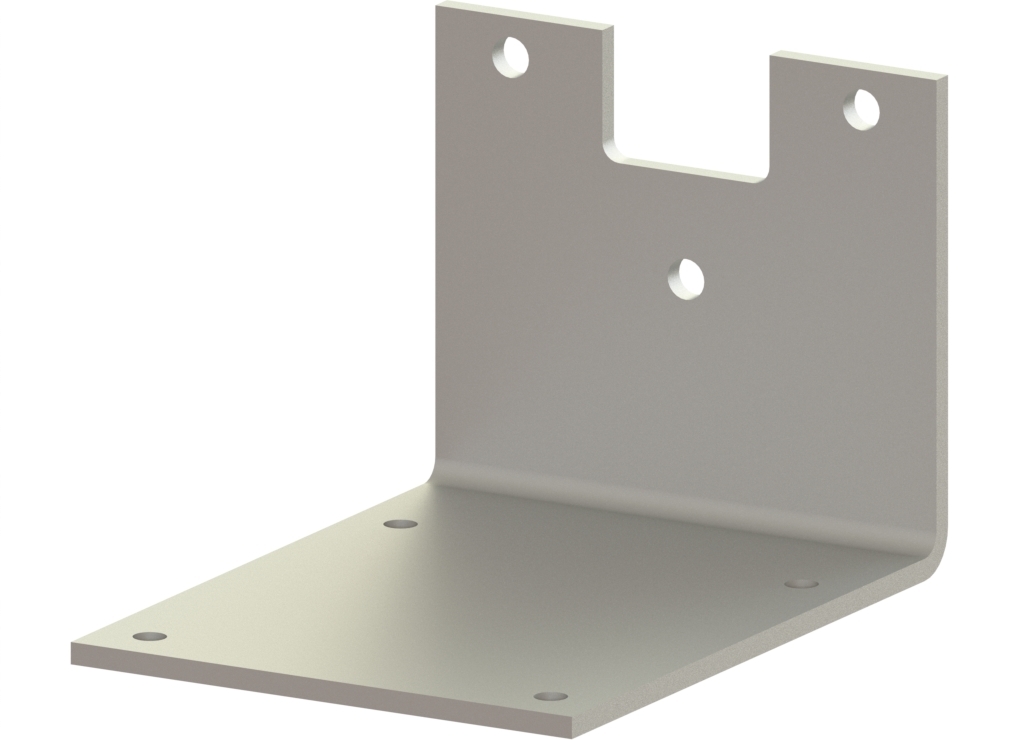

Mounting plate

| Article | Article name | A [mm] | H [mm] | m [kg] |

| P.MP.GW.H.A90 | Mounting plate GW right angle A90 H101 | 90 | 101 | 1,9 |

| P.MP.GW.H.A122 | Mounting plate GW right angle A122 H133 | 122 | 133 | 2,2 |

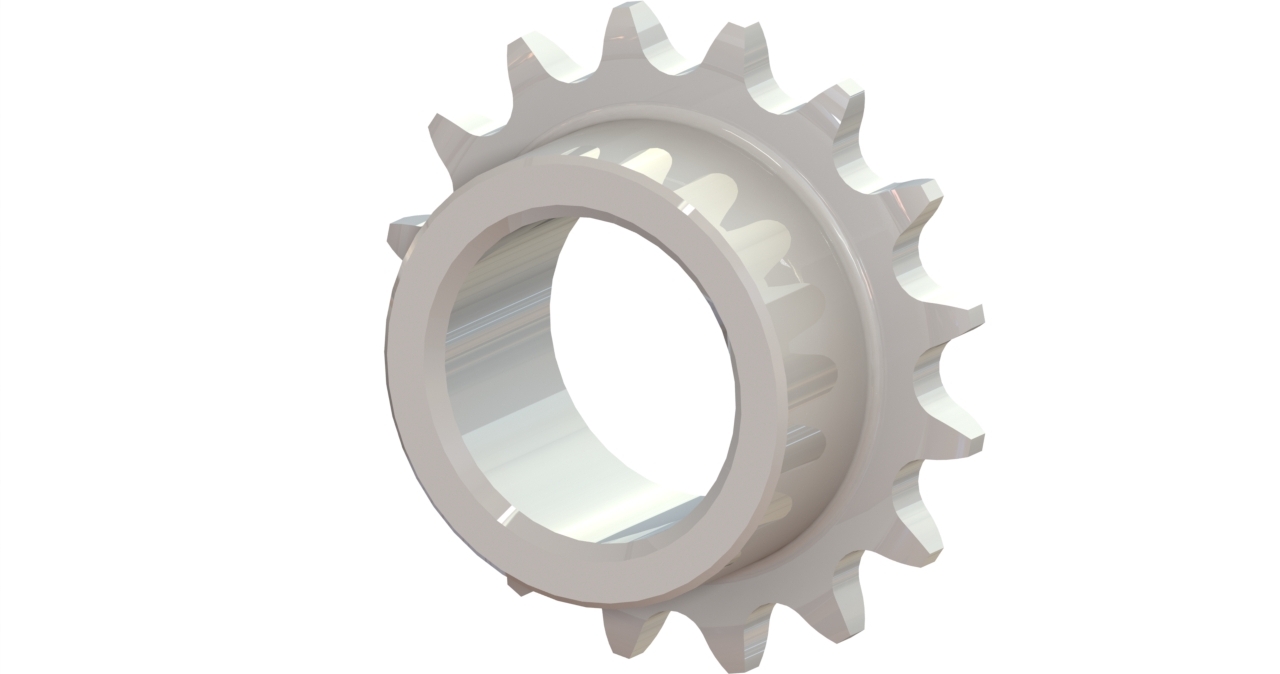

Tube bolt sprocket

| Article | Description | Tmax [Nm] | Db [mm] | D [mm] | L [mm] | m [kg] |

| P.BBKWL10B.Z16.D125 | Tube bolt sprocket 10B z16 - 5/4" | 420 | 43 | 96 | 145 | 0,7 |

2 P.BBKWL10B.Z16.D125 13 Tube bolt sprocket 10B z16 - 5/4" 15 16 P.BBKWL10B.Z16.D125.jpg 17 10 CAT_P.BBKWL10B.Z16.D125_2D.gif |

Weld sprocket

| Article | Description | Chain | Shaft | Tmax [Nm] | Db [mm] | D [mm] | L [mm] | m [kg] |

| P.LKWL10B.Z16.D125 | Weld sprocket 10B z16 - 5/4" | 10B z16 | D125 | 420 | 43 | 96 | 30 | 0,4 |

2 P.LKWL10B.Z16.D125 11 Weld sprocket 10B z16 - 5/4" 12 13 P.LKWL10B.Z16.D125.jpg 15 16 CAT_P.LKWL10B.Z16.D125_2D.gif 17 10 |

Prefab 5/4" drive shaft

| Article | Description | Lb [mm] | L [mm] | Tmax [Nm] | Z [teeth] | m [kg] |

| P.BKK10B.D25.D125.L08 | Tube with CC set10B D25 z16 5/4" L0750 | 750 | 800 | 420 | 16 | 3,4 |

2 P.BKK10B.D25.D125.L08 11 Tube with CC set10B D25 z16 5/4" L0750 12 13 P.BBKK10B.D00.D000.jpg 14 10 CAT_P.BKK10B.D25.D125.L00_2D.gif | ||||||

| P.BKK10B.D25.D125.L20 | Tube for CC set 10B D25 z16 5/4" L2000 | 2000 | 2050 | 420 | 16 | 6,5 |

2 P.BKK10B.D25.D125.L20 11 Tube for CC set 10B D25 z16 5/4" L2000 12 13 P.BBKK10B.D00.D000.jpg 14 10 CAT_P.BKK10B.D25.D125.L00_2D.gif | ||||||

| P.BKK10B.D25.D125.L30 | Tube with CC set 10B D25 z16 5/4" L3000 | 3000 | 3050 | 420 | 16 | 8,9 |

2 P.BKK10B.D25.D125.L30 11 Tube with CC set 10B D25 z16 5/4" L3000 12 13 P.BBKK10B.D00.D000.jpg 14 10 CAT_P.BKK10B.D25.D125.L00_2D.gif | ||||||

| P.BKK10B.D25.D125.L42 | Tube with CC set 10B D25 z16 5/4" L4200 | 4200 | 4250 | 420 | 16 | 12 |

2 P.BKK10B.D25.D125.L42 11 Tube with CC set 10B D25 z16 5/4" L4200 12 13 P.BBKK10B.D00.D000.jpg 14 10 CAT_P.BKK10B.D25.D125.L00_2D.gif |

Winch drum tube 5/4"

| Article | Description | B [mm] | L [mm] | D1 [mm] | m [kg] |

| P.LT2.D125 | Winch drum (double) tube 5/4" W=84 | 42 | 110 | 55 | 2,8 |

| P.LT2.D125.300 | Winch drum (double) tube 5/4" W=300 | 150 | 326 | 55 | 4,5 |

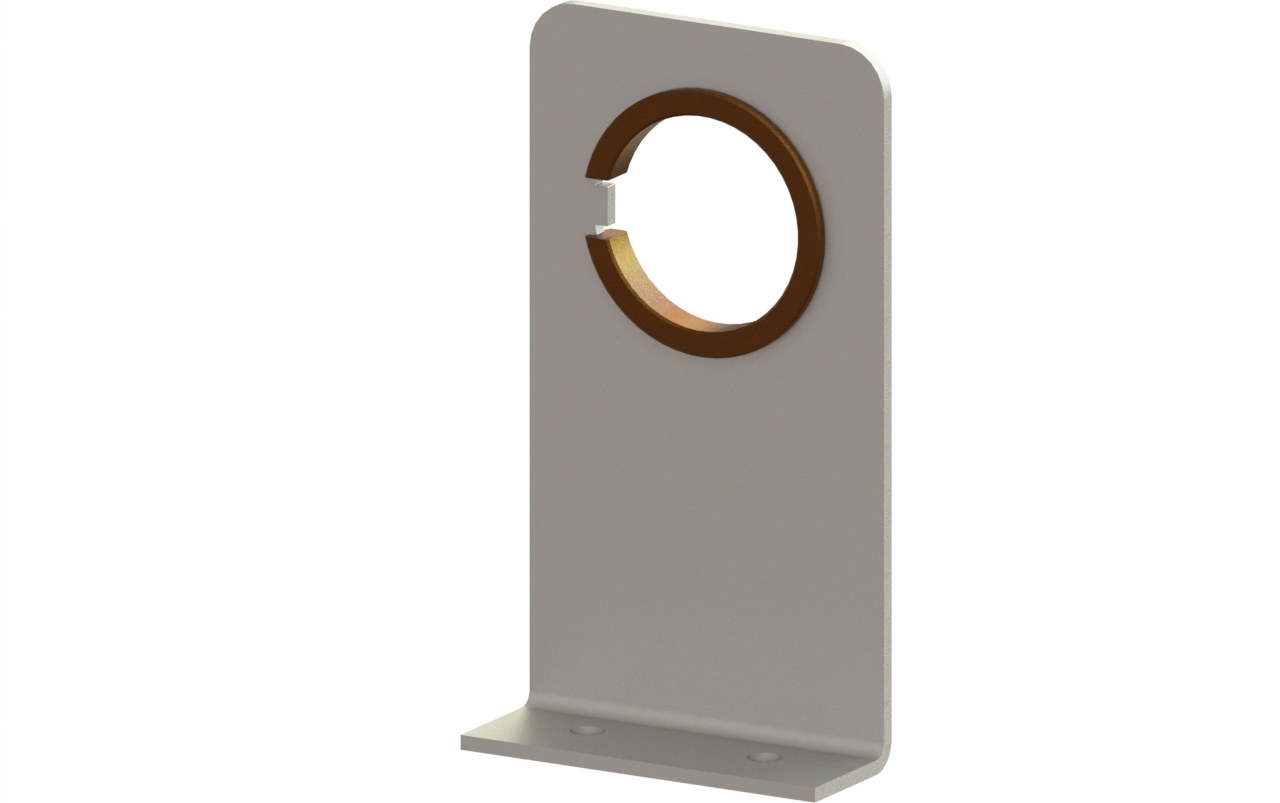

Ball bearing plates

| Article | Article name | A [mm] | L [mm] | m [kg] |

| P.KL125.H.A89 | Ball bearing plate 5/4" H A89 H135 | 89 | 135 | 0,6 |

| P.KL125.H.A122 | Ball bearing plate 5/4" H A122 H168 | 122 | 168 | 0,7 |

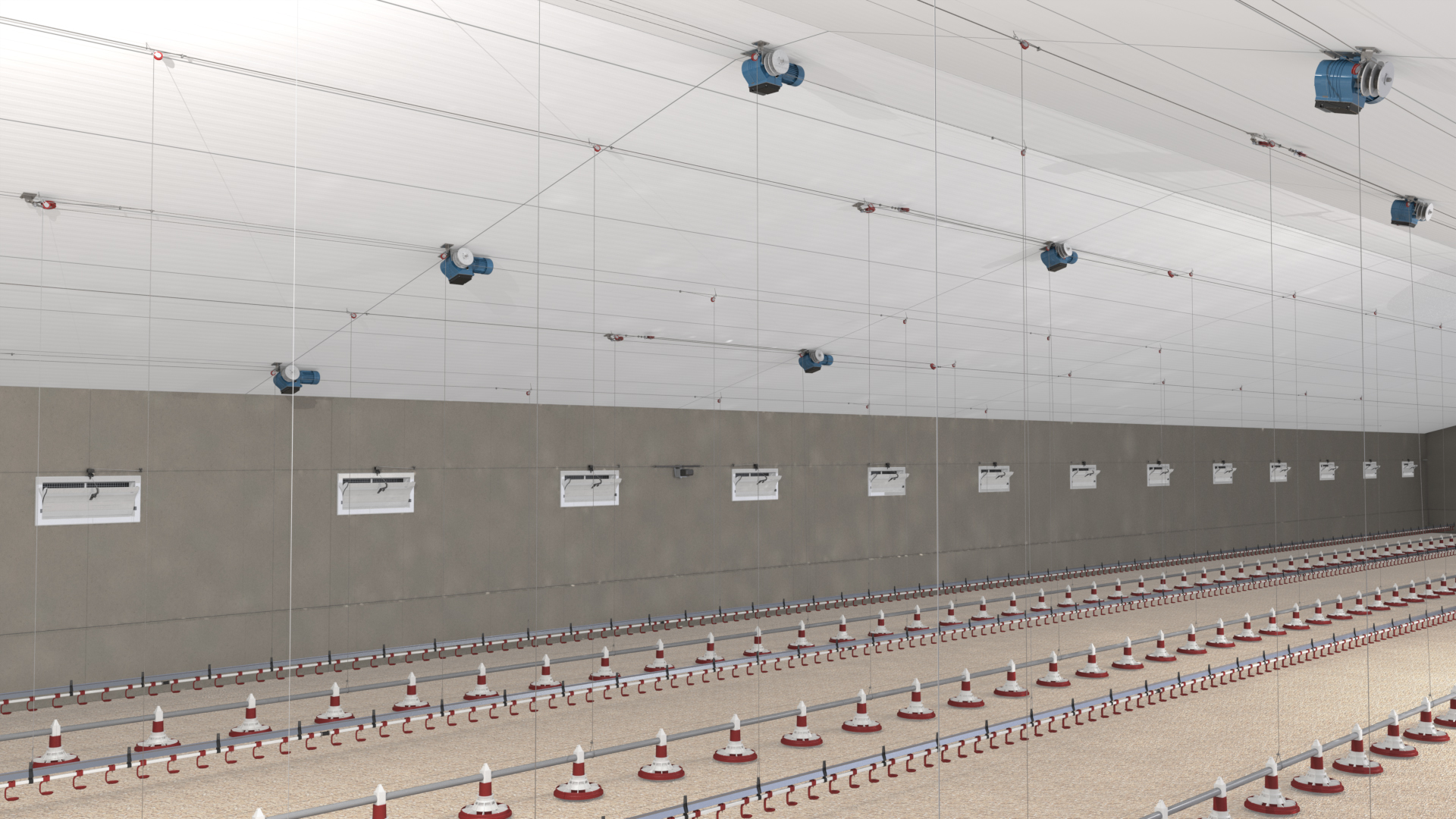

Drive systems for hoisting

The welfare of poultry is not only in the right climate, but also in feed and water at the right height for optimale feed consumption. To overcome height differences, drinking and feeding lines, adjustable platforms and suspended heaters must be lifted. This requires the necessary precision that it will positioned on the right height, not too high or not too low. For this we supply a complete range of winch drives that have been specially developed for this purpose. Equipped with special winch drums, we offer powerful, high precision hoisting systems.

Single feed pan system L2 winch motor

We are happy to help you with making a calculation

Get in contact with usA GW winchmotor with a double winch drum is mounted against the roof and located centrally above the feeding line. The feed pan system is directly connected by the drive (1:1) to the L2 winch drum.

- Direct control by dedicated winch motor.

- Powerful self-locking GW motor gearboxes.

- Wide selection of 1-phase and 3-phase 50/60Hz motors.

- Complete package of couplings, bearing plates and components.

- UL/CSA for United States and Canadian market.

- Precise switching by integrated limit switch.

GW motor gearbox

| Article | Description | T (50/60Hz) [Nm] | n (50/60Hz) [rpm] | L [mm] | D [mm] | P (50/60Hz) [kW] | I (@ Y) (50/60Hz) [A] | I (@ Δ) (50/60Hz) [A] | m [kg] |

| P.GW10.3.230.52.L | GW10 5.2 1ph 230V for winch drum | 100 / - | 5,2 / - | 191 | 124 | 0,18 / - | 1,3 / - | - | 24 |

2 P.GW10.3.230.52.L 11 GW10 5.2 1ph 230V for winch drum 12 13 P.GW10.400.26.L.jpg 14 15 CAT_P.GW10.400.26.L_2D.gif 17 16 10 | |||||||||

| P.GW30.230.52.L | GW30 5.2 1ph 230V for winch drum | 300 / - | 5,2 / - | 220 | 145 | 0,55 / - | 4,5 / - | - | 30 |

2 P.GW30.230.52.L 11 GW30 5.2 1ph 230V for winch drum 12 13 P.GW30.400.26.L.jpg 14 15 CAT_P.GW30.400.26.L_2D.gif 17 16 10 | |||||||||

| P.GW40.3.230.52.L | GW40 5.2 1ph 230V for winch drum | 400 / - | 5,2 / - | 242 | 159 | 0,55 / - | 4,4 / - | - | 36 |

2 P.GW40.3.230.52.L 11 GW40 5.2 1ph 230V for winch drum 12 13 P.GW40.400.26.L.jpg 14 15 CAT_P.GW40.400.26.L_2D.gif 17 16 10 | |||||||||

| P.GW10.3.400.52.L | GW10 5.2 3ph 400V for winch drum | 100 / 80 | 5,2 / 6,2 | 191 | 124 | 0,18 / 0,22 | 0,7 / 0,7 | 1,2 / 1,2 | 24 |

2 P.GW10.3.400.52.L 11 GW10 5.2 3ph 400V for winch drum 12 13 P.GW10.400.26.L.jpg 14 15 CAT_P.GW10.400.26.L_2D.gif 17 16 10 | |||||||||

| P.GW30.400.52.L | GW30 5.2 3ph 400V for winch drum | 300 / 240 | 5,2 / 6,3 | 220 | 145 | 0,37 / 0,44 | 1,2 / 1,2 | 2,1 / 2,1 | 30 |

2 P.GW30.400.52.L 11 GW30 5.2 3ph 400V for winch drum 12 13 P.GW30.400.26.L.jpg 14 15 CAT_P.GW30.400.26.L_2D.gif 17 16 10 | |||||||||

| P.GW40.3.400.52.L | GW40 5.2 3ph 400V for winch drum | 400 / 320 | 5,2 / 6,2 | 220 | 137 | 0,55 / 0,66 | 1,5 / 1,5 | 2,6 / 2,6 | 32 |

2 P.GW40.3.400.52.L 11 GW40 5.2 3ph 400V for winch drum 12 13 P.GW40.400.26.L.jpg 14 15 CAT_P.GW40.400.26.L_2D.gif 17 16 10 |

Mounting plate

| Article | Article name | A [mm] | H [mm] | m [kg] |

| P.MP.GW.H.A100 | Mounting plate GW right angle A100 H111 | 100 | 111 | 2,0 |

| P.MP.GW.H.A122 | Mounting plate GW right angle A122 H133 | 122 | 133 | 2,2 |

Cable winch drum

| Article | Description | B1 [mm] | B2 [mm] | D1 [mm] | m [kg] |

| P.LT2.GW10 | Double cable winch drum GW10 D50 D120 | 90 | 28 | 50 | 2,8 |

| P.LT2.GW | Double cable winch drum GW20/30/40 | 90 | 28 | 50 | 2,8 |

Drive systems for hoisting

The welfare of poultry is not only in the right climate, but also in feed and water at the right height for optimale feed consumption. To overcome height differences, drinking and feeding lines, adjustable platforms and suspended heaters must be lifted. This requires the necessary precision that it will positioned on the right height, not too high or not too low. For this we supply a complete range of winch drives that have been specially developed for this purpose. Equipped with special winch drums, we offer powerful, high precision hoisting systems.

Single feed pan system on central shaft

We are happy to help you with making a calculation

Get in contact with usThe motor gearbox with a shaft coupled on both sides is mounted longitudinally on the roof and suspended with slide bearings and glide bearings. Cords connected to the feeding line are wrapped on the drive shaft . The feed line is aligned by rotating the shaft.

- Efficient and reliable solution.

- Wide selection of 1-phase and 3-phase 50/60Hz motors.

- Complete package of couplings, bearing plates and components.

- UL/CSA for United States and Canadian market.

- Precise switching by integrated limit switch.

GW motor gearbox

| Article | Description | T (50/60Hz) [Nm] | n (50/60Hz) [rpm] | L [mm] | D [mm] | P (50/60Hz) [kW] | I (@ Y) (50/60Hz) [A] | I (@ Δ) (50/60Hz) [A] | m [kg] |

| P.GW10.3.230.52.KW | GW10 5.2 1ph 230V with CW+CH 10B z16 | 100 / - | 5,2 / - | 191 | 124 | 0,18 / - | 1,3 / - | - | 24 |

2 P.GW10.3.230.52.KW 11 GW10 5.2 1ph 230V with CW+CH 10B z16 12 13 P.GW10.400.26.KW.jpg 14 15 CAT_P.GW10.400.26.KW_2D.gif 17 16 10 | |||||||||

| P.GW10.3.400.52.KW | GW10 5.2 3ph 400V with CW+CH 10B z16 | 100 / 80 | 5,2 / 6,2 | 191 | 124 | 0,18 / 0,22 | 0,7 / 0,7 | 1,2 / 1,2 | 24 |

2 P.GW10.3.400.52.KW 11 GW10 5.2 3ph 400V with CW+CH 10B z16 12 13 P.GW10.400.26.KW.jpg 14 15 CAT_P.GW10.400.26.KW_2D.gif 17 16 10 | |||||||||

| P.GW30.2.230.52.KW | GW30 5.2 1ph 230V with CW+CH 10B z16 | 300 / - | 5,2 / - | 220 | 145 | 0,55 / - | 4,5 / - | - | 27 |

2 P.GW30.2.230.52.KW 11 GW30 5.2 1ph 230V with CW+CH 10B z16 12 13 P.GW30.400.26.KW.jpg 14 15 CAT_P.GW30.400.26.KW_2D.gif 17 16 10 | |||||||||

| P.GW30.400.52.KW | GW30 5.2 3ph 400V with CW+CH 10B z16 | 300 / 240 | 5,2 / 6,2 | 220 | 145 | 0,37 / 0,44 | 1,2 / 1,2 | 2,1 / 2,1 | 27 |

2 P.GW30.400.52.KW 11 GW30 5.2 3ph 400V with CW+CH 10B z16 12 13 P.GW30.400.26.KW.jpg 14 15 CAT_P.GW30.400.26.KW_2D.gif 17 16 10 | |||||||||

| P.GW40.3.230.52.KW | GW40 5.2 1ph 230V with CW+CH 10B z16 | 400 / - | 5,2 / - | 242 | 159 | 0,55 / - | 4,4 / - | - | 29 |

2 P.GW40.3.230.52.KW 11 GW40 5.2 1ph 230V with CW+CH 10B z16 12 13 P.GW80.400.26.KW.jpg 14 15 CAT_P.GW80.400.26.KW_2D.gif 17 16 10 | |||||||||

| P.GW40.3.400.52.KW | GW40 5.2 3ph 400V with CW+CH 10B z16 | 400 / 320 | 5,2 / 6,2 | 220 | 137 | 0,55 / 0,66 | 1,5 / 1,5 | 2,6 / 2,6 | 29 |

2 P.GW40.3.400.52.KW 11 GW40 5.2 3ph 400V with CW+CH 10B z16 12 13 P.GW80.400.26.KW.jpg 14 15 CAT_P.GW80.400.26.KW_2D.gif 17 16 10 |

Mounting plate

| Article | Article name | A [mm] | H [mm] | m [kg] |

| P.MP.GW.H.A100 | Mounting plate GW right angle A100 H111 | 100 | 111 | 2,0 |

| P.MP.GW.H.A122 | Mounting plate GW right angle A122 H133 | 122 | 133 | 2,2 |

Tube bolt sprocket

| Article | Description | Chain | Shaft | Tmax [Nm] | Db [mm] | D [mm] | L [mm] | m [kg] |

| P.BBKWL10B.Z16.D100 | Tube bolt sprocket 10B z16 - 1" | 10B z16 | D100 | 420 | 34 | 96 | 150 | 0,8 |

2 P.BBKWL10B.Z16.D100 11 Tube bolt sprocket 10B z16 - 1" 12 13 P.BBKWL10B.Z16.D100.jpg 15 16 CAT_P.BBKWL10B.Z16.D100_2D.gif 17 10 | ||||||||

| P.BBKWL10B.Z16.D125 | Tube bolt sprocket 10B z16 - 5/4" | 10B z16 | D125 | 420 | 43 | 96 | 145 | 0,7 |

2 P.BBKWL10B.Z16.D125 11 Tube bolt sprocket 10B z16 - 5/4" 12 13 P.BBKWL10B.Z16.D125.jpg 15 16 CAT_P.BBKWL10B.Z16.D125_2D.gif 17 10 |

Weld sprocket

| Article | Description | Chain | Shaft | Tmax [Nm] | Db [mm] | D [mm] | L [mm] | m [kg] |

| P.LKWL10B.Z16.D100 | Weld sprocket 10B z16 - 1" and 2" | 10B z16 | D100 | 420 | 34 | 96 | 30 | 0,5 |

2 P.LKWL10B.Z16.D100 11 Weld sprocket 10B z16 - 1" and 2" 12 13 P.LKWL10B.Z16.D100.jpg 15 16 CAT_P.LKWL10B.Z16.D100_2D.gif 17 10 | ||||||||

| P.LKWL10B.Z16.D125 | Weld sprocket 10B z16 - 5/4" | 10B z16 | D125 | 420 | 43 | 96 | 30 | 0,4 |

2 P.LKWL10B.Z16.D125 11 Weld sprocket 10B z16 - 5/4" 12 13 P.LKWL10B.Z16.D125.jpg 15 16 CAT_P.LKWL10B.Z16.D125_2D.gif 17 10 |

Slide bearing plate

| Article | Description | A [mm] | H [mm] | L [mm] | m [kg] |

| P.GL100.H.L158 | Slide bearing plate 1" H A100 L158 mm | 100 | 133 | 158 | 0,2 |

| P.GL100.H.L180 | Slide bearing plate 1" H A122 L180 mm | 122 | 155 | 180 | 0,2 |

| P.GL125.H.L186 | Slide bearing plate 5/4" H A122 L186 mm | 122 | 162 | 186 | 0,3 |

Cable ring

| Article | Description | D1 [mm] | D2 [mm] | m [kg] |

| P.KABELRING | Cable clamp 1" d36 D50 4xØ4,5 | 50 | 36 | 0,09 |

| P.KABELRING.D125 | Cable clamp 1-1/4" d44 D60 4xØ4,5 | 60 | 44 | 0,11 |

Drive systems for hoisting

The welfare of poultry is not only in the right climate, but also in feed and water at the right height for optimale feed consumption. To overcome height differences, drinking and feeding lines, adjustable platforms and suspended heaters must be lifted. This requires the necessary precision that it will positioned on the right height, not too high or not too low. For this we supply a complete range of winch drives that have been specially developed for this purpose. Equipped with special winch drums, we offer powerful, high precision hoisting systems.

De Gier Drive Systems

+ 31 174 29 20 89