Horizontal wire screening

We are happy to help you with making a calculation

Get in contact with usHorizontal screen systems are used in Venlo, wide-span and poly greenhouses. In a wire screen application, the screen is driven by pull wires. The pull wires are driven by a GW motor gearbox via a 2" winding tube equipped with (profiled) wire drums.

- Modern, refined application.

- Maximum light yield, minimum shadow.

- Minimal mechanical parts.

- Dedicated GW screen drives.

- Optional feedback to climate computer.

- Easy installation and maintenance.

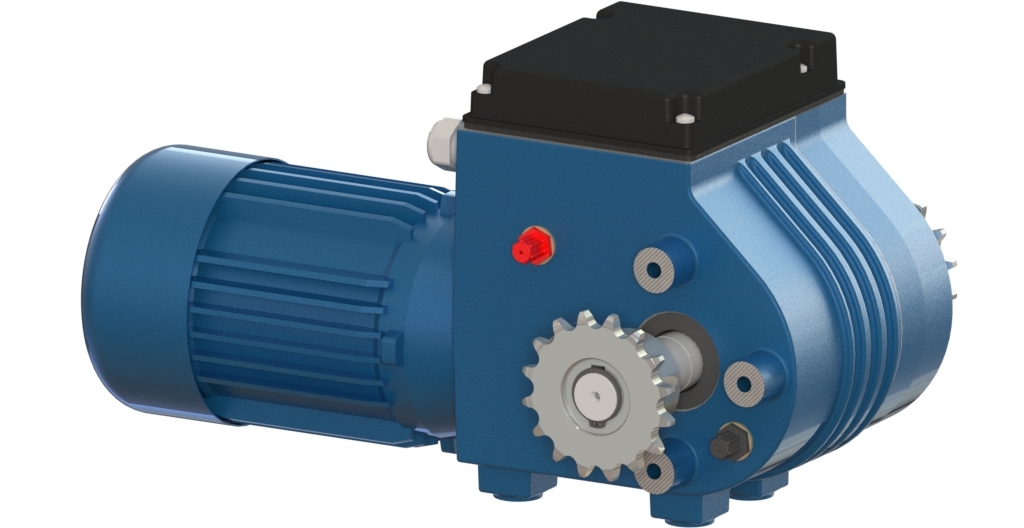

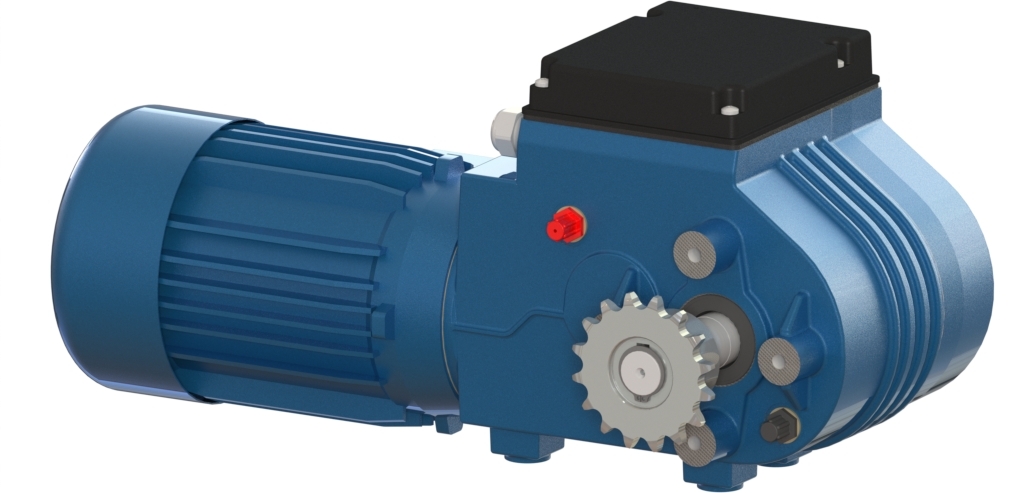

GW motor gearbox

| Article | Description | T (50/60Hz) [Nm] | n (50/60Hz) [rpm] | L [mm] | D [mm] | P (50/60Hz) [kW] | I (@ Y) (50/60Hz) [A] | I (@ Δ) (50/60Hz) [A] | m [kg] |

| P.GW10.3.400.26.KW | GW10 2.6 3ph 400V with CW+CH 10B z16 | 100 / 80 | 2,6 / 3,1 | 168 | 124 | 0,09 / 0,11 | 0,4 / 0,4 | 0,7 / 0,7 | 21 |

2 P.GW10.3.400.26.KW 11 GW10 2.6 3ph 400V with CW+CH 10B z16 12 13 P.GW10.400.26.KW.jpg 14 15 CAT_P.GW10.400.26.KW_2D.gif 17 16 10 | |||||||||

| P.GW10.3.400.52.KW | GW10 5.2 3ph 400V with CW+CH 10B z16 | 100 / 80 | 5,2 / 6,2 | 191 | 124 | 0,18 / 0,22 | 0,7 / 0,7 | 1,2 / 1,2 | 24 |

2 P.GW10.3.400.52.KW 11 GW10 5.2 3ph 400V with CW+CH 10B z16 12 13 P.GW10.400.26.KW.jpg 14 15 CAT_P.GW10.400.26.KW_2D.gif 17 16 10 | |||||||||

| P.GW30.400.26.KW | GW30 2.6 3ph 400V with CW+CH 10B z16 | 300 / 240 | 2,6 / 3,1 | 220 | 145 | 0,25 / 0,30 | 0,8 / 0,8 | 1,4 / 1,4 | 24 |

2 P.GW30.400.26.KW 11 GW30 2.6 3ph 400V with CW+CH 10B z16 12 13 P.GW30.400.26.KW.jpg 14 15 CAT_P.GW30.400.26.KW_2D.gif 17 16 10 | |||||||||

| P.GW30.400.52.KW | GW30 5.2 3ph 400V with CW+CH 10B z16 | 300 / 240 | 5,2 / 6,2 | 220 | 145 | 0,37 / 0,44 | 1,2 / 1,2 | 2,1 / 2,1 | 27 |

2 P.GW30.400.52.KW 11 GW30 5.2 3ph 400V with CW+CH 10B z16 12 13 P.GW30.400.26.KW.jpg 14 15 CAT_P.GW30.400.26.KW_2D.gif 17 16 10 | |||||||||

| P.GW40.400.26.KW | GW40 2.6 3ph 400V with CW+CH 10B z16 | 400 / 320 | 2,6 / 3,1 | 220 | 159 | 0,37 / 0,44 | 1,0 / 1,0 | 1,7 / 1,7 | 29 |

2 P.GW40.400.26.KW 11 GW40 2.6 3ph 400V with CW+CH 10B z16 12 13 P.GW80.400.26.KW.jpg 14 15 CAT_P.GW80.400.26.KW_2D.gif 17 16 10 | |||||||||

| P.GW40.3.400.52.KW | GW40 5.2 3ph 400V with CW+CH 10B z16 | 400 / 320 | 5,2 / 6,2 | 220 | 137 | 0,55 / 0,66 | 1,5 / 1,5 | 2,6 / 2,6 | 29 |

2 P.GW40.3.400.52.KW 11 GW40 5.2 3ph 400V with CW+CH 10B z16 12 13 P.GW80.400.26.KW.jpg 14 15 CAT_P.GW80.400.26.KW_2D.gif 17 16 10 | |||||||||

| P.GW80.400.26.KW | GW80 2.6 3ph 400V with CW+CH 10B z16 | 800 / 640 | 2,6 / 3,1 | 218 | 159 | 0,55 / 0,66 | 1,5 / 1,5 | 2,6 / 2,6 | 31 |

2 P.GW80.400.26.KW 11 GW80 2.6 3ph 400V with CW+CH 10B z16 12 13 P.GW80.400.26.KW.jpg 14 15 CAT_P.GW80.400.26.KW_2D.gif 17 16 10 | |||||||||

| P.GW80.2.400.40.KW | GW80 4.0 3ph 400V with CW+CH 10B z16 d25 | 800 / 640 | 4,0 / 4,8 | 242 | 159 | 0,75 / 0,90 | 2,0 / 2,0 | 3,5 / 3,5 | 38 |

2 P.GW80.2.400.40.KW 11 GW80 4.0 3ph 400V with CW+CH 10B z16 d25 12 13 P.GW80.400.26.KW.jpg 14 15 CAT_P.GW80.400.26.KW_2D.gif 17 16 10 | |||||||||

| P.GW110S.400.40.KW | GW110S 4.0 3ph 400V with CW+CH 12B z18 | 1100 / 957 | 4,0 / 4,8 | 242 | 159 | 1,10 / 1,32 | 2,7 / 2,7 | 4,7 / 4,7 | 38 |

2 P.GW110S.400.40.KW 11 GW110S 4.0 3ph 400V with CW+CH 12B z18 12 13 P.GW150S.400.40.KW.jpg 14 15 CAT_P.GW150S.400.40.KW_2D.gif 17 16 10 | |||||||||

| P.GW150S.400.40.KW | GW150S 4.0 3ph 400V with CW+CH 12B z18 | 1500 / 1200 | 4,0 / 4,8 | 280 | 176 | 1,50 / 1,80 | 3,7 / 3,7 | 6,4 / 6,4 | 39 |

2 P.GW150S.400.40.KW 11 GW150S 4.0 3ph 400V with CW+CH 12B z18 12 13 P.GW150S.400.40.KW.jpg 14 15 CAT_P.GW150S.400.40.KW_2D.gif 17 16 10 |

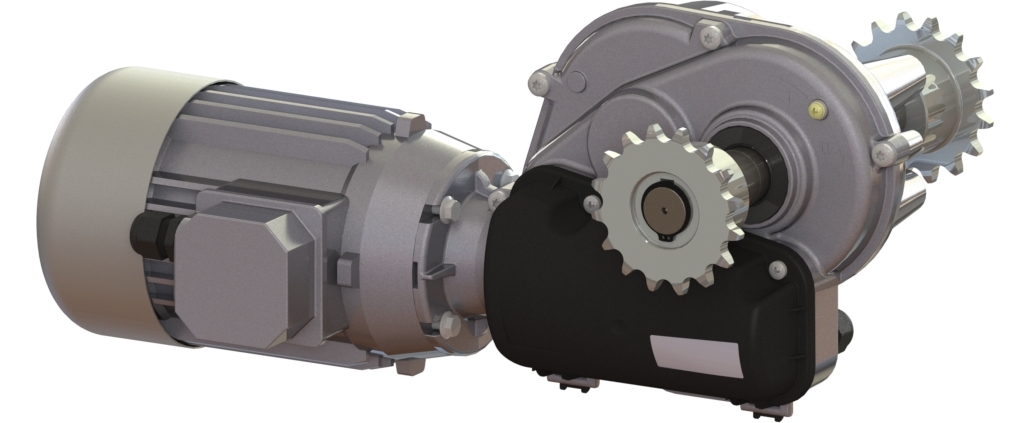

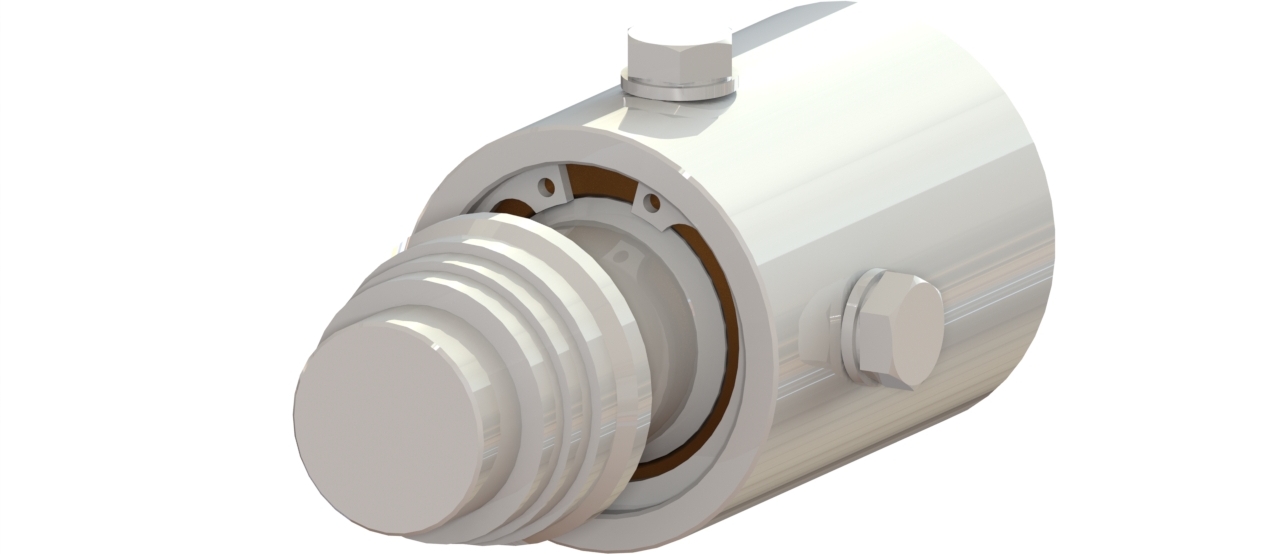

GWM motor gearbox

| Article | Description | T (50/60Hz) Nm | n (50/60Hz) [rpm] | i [-] | s [-] | P (50/60Hz) [kW] | I (@ Y) (50/60Hz) [A] | I (@ Δ) (50/60Hz) [A] | m [kg] |

| P.GWM30.1.400.26.KW | GWM30 2.6 3ph 400V with cw+ch 10B z16 | 300 / 240 | 2,6 / 3,1 | 505 | 0,75-42 | 0,25 / 0,30 | 0,8 / 1,0 | 1,4 / 1,7 | 17 |

2 P.GWM30.1.400.26.KW 11 GWM30 2.6 3ph 400V with cw+ch 10B z16 12 13 P.GWM30.1.400.26.KW.jpg 14 15 CAT_P.GWM30.1.400.26.KW_2D.gif 17 16 10 | |||||||||

| P.GWM45.1.400.26.KW | GWM45 2.6 3ph 400V with cw+ch 10B z16 | 450 / 360 | 2,6 / 3,1 | 505 | 0,75-42 | 0,37 / 0,44 | 1,0 / 1,2 | 1,7 / 2,1 | 17 |

2 P.GWM45.1.400.26.KW 11 GWM45 2.6 3ph 400V with cw+ch 10B z16 12 13 P.GWM30.1.400.26.KW.jpg 14 15 CAT_P.GWM30.1.400.26.KW_2D.gif 17 16 10 |

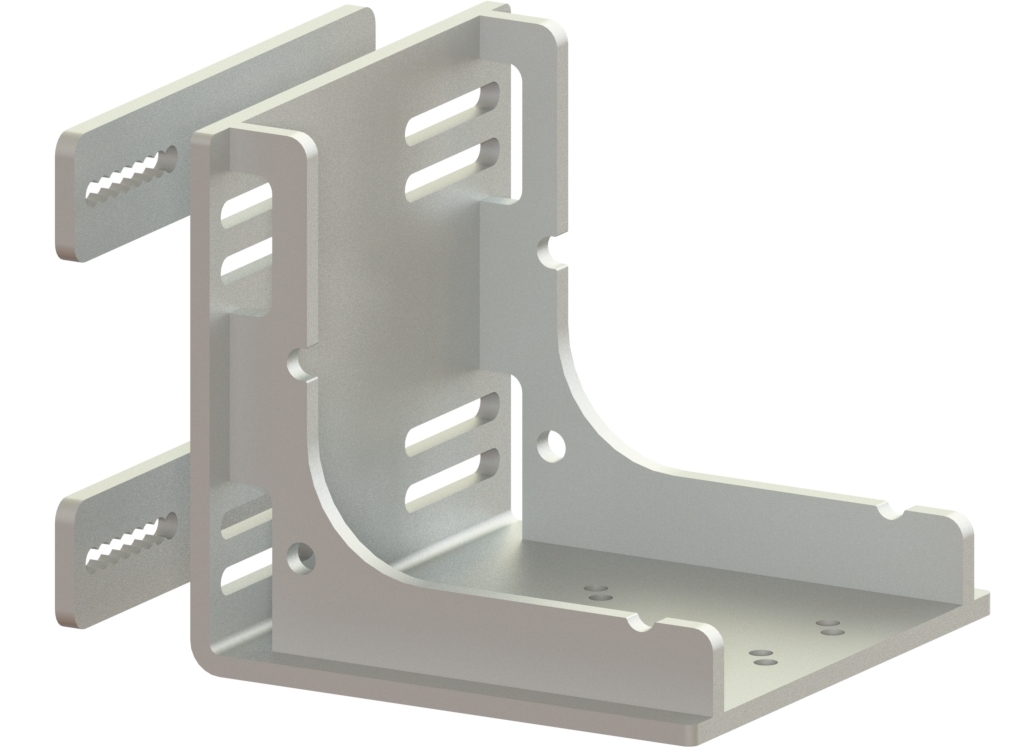

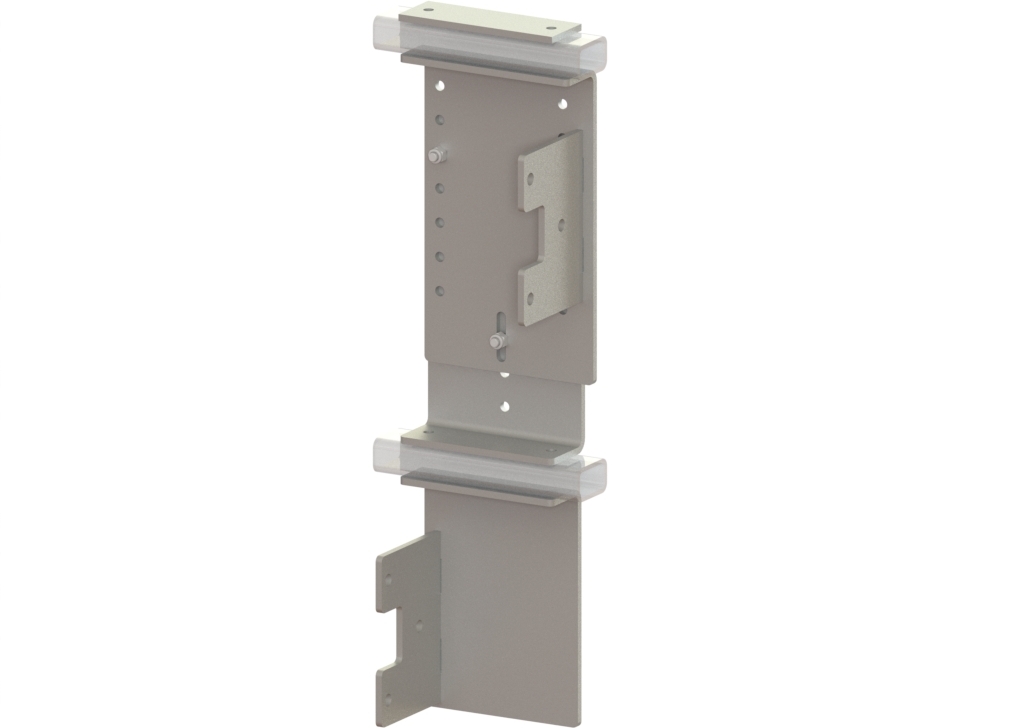

Mounting seat GW30/40/80/150S

| Article | Description | L [mm] | B [mm] | H [mm] | m [kg] |

| P.MP.GWS.01 | Mounting seat GW30/80 incl. CP | 260 | 240 | 240 | 7,9 |

| P.MP.GWS.02 | Mounting seat GW110S/150S incl. CP | 260 | 270 | 250 | 14,2 |

Mounting set mounting seat

| Article | Description | B [mm] | m [kg] |

| P.MP.GWS.BVM.50 | Mounting seat mounting set column 50 | 50 | 0,5 |

| P.MP.GWS.BVM.60 | Mounting seat mounting set column 60 | 60 | 0,5 |

| P.MP.GWS.BVM.80 | Mounting seat mounting set column 70/80 | 80 | 0,6 |

| P.MP.GWS.BVM.100 | Mounting seat mounting set column 100 | 100 | 0,7 |

| P.MP.GWS.BVM.120 | Mounting seat mounting set column 120 | 120 | 0,8 |

| P.MP.GWS.BVM.140 | Mounting seat mounting set column 140 | 140 | 0,8 |

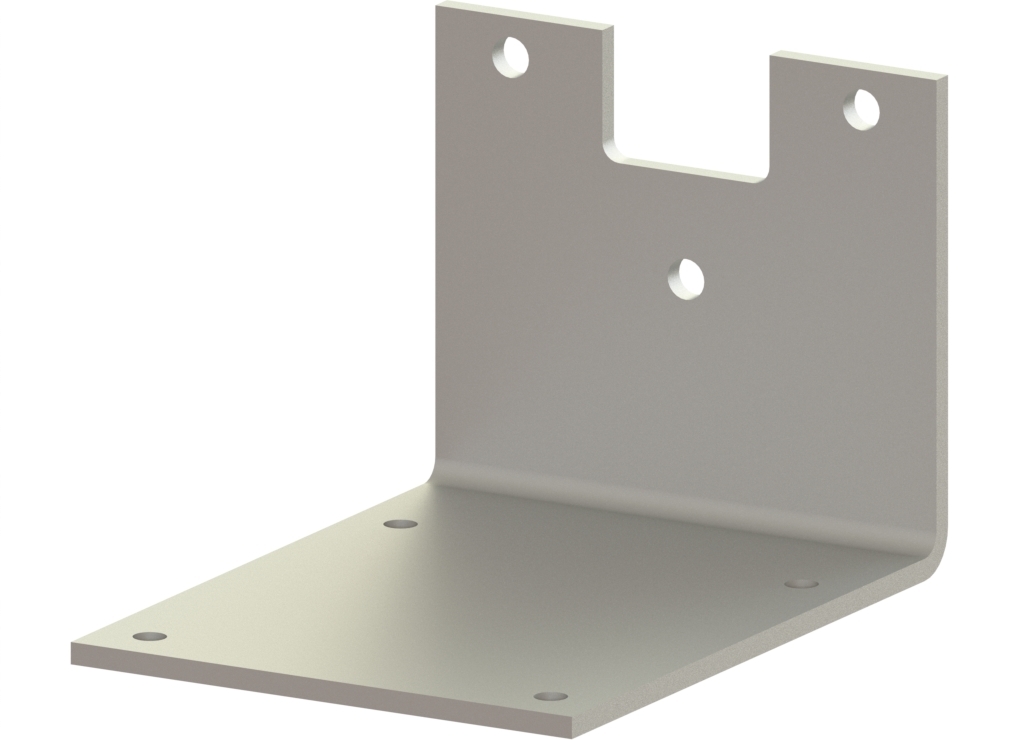

Mounting plate GW right angle

| Article | Description | H [mm] | A [mm] | m [kg] |

| P.MP.GW.H.A100 | Mounting plate GW right angle A100 H111 | 111 | 100 | 2,0 |

Mounting plate GWM straight

| Article | Description | A [mm] | L [mm] | m [kg] |

| P.MP.GWM.R.A163 | Mounting plate GWM straight A163 L204 | 163 | 204 | 0,9 |

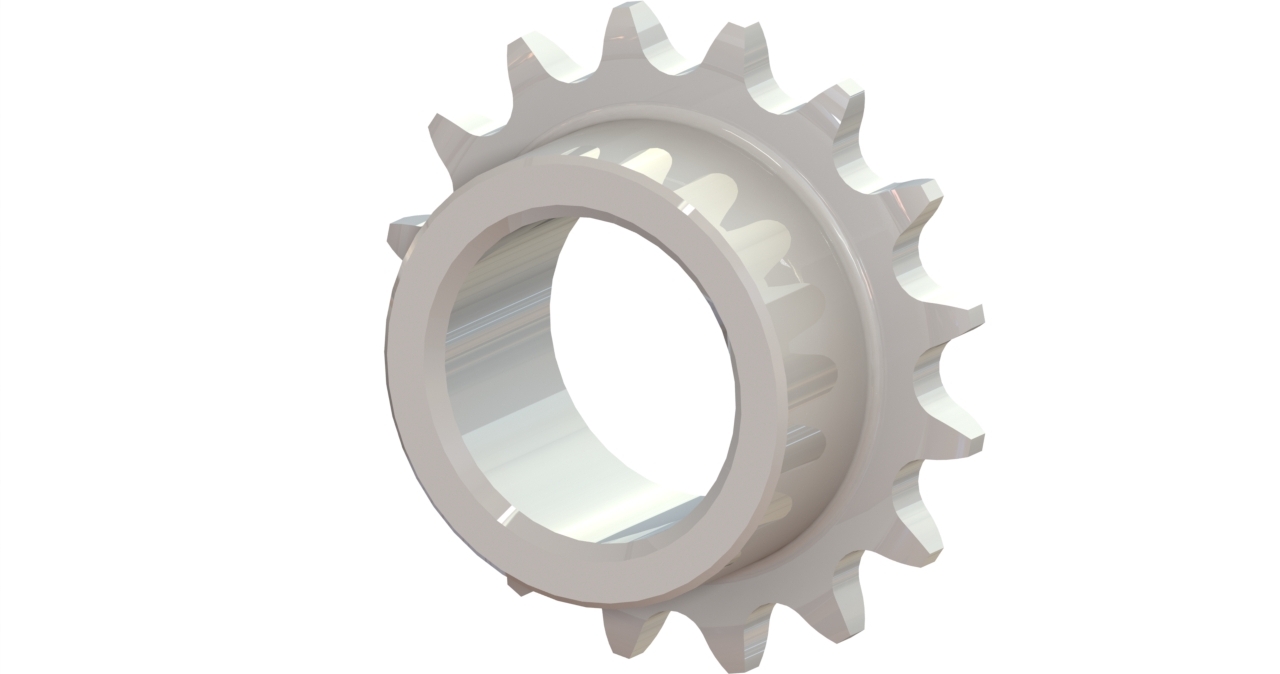

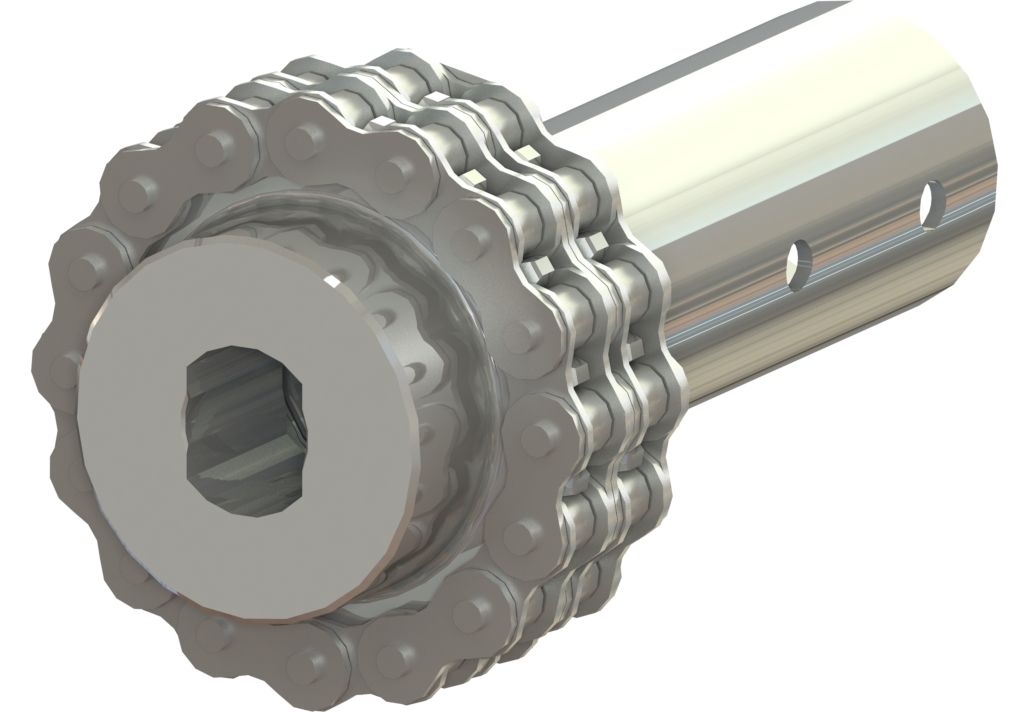

Weld sprockets

| Article | Description | Chain | Shaft | Tmax [Nm] | Db [mm] | D [mm] | L [mm] | m [kg] |

| P.LKWL10B.Z16.D125 | Weld sprocket 10B z16 - 5/4" | 10B z16 | D125 | 420 | 43 | 96 | 30 | 0,4 |

2 P.LKWL10B.Z16.D125 11 Weld sprocket 10B z16 - 5/4" 12 13 P.LKWL10B.Z16.D125.jpg 15 16 CAT_P.LKWL10B.Z16.D125_2D.gif 17 10 | ||||||||

| P.LKWL10B.Z16.D200 | Weld sprocket 10B z16 - 1" and 2" | 10B z16 | D200 | 420 | 61 | 96 | 30 | 0,7 |

2 P.LKWL10B.Z16.D200 11 Weld sprocket 10B z16 - 1" and 2" 12 13 P.LKWL10B.Z16.D125.jpg 15 16 CAT_P.LKWL10B.Z16.D125_2D.gif 17 10 | ||||||||

| P.LKWL12B.Z18.D200 | Weld sprocket 12B z18 - 1" | 12B z18 | D200 | 760 | 61 | 126 | 34 | 0,8 |

2 P.LKWL12B.Z18.D200 11 Weld sprocket 12B z18 - 1" 12 13 P.LKWL10B.Z16.D125.jpg 15 16 CAT_P.LKWL10B.Z16.D100_2D.gif 17 10 |

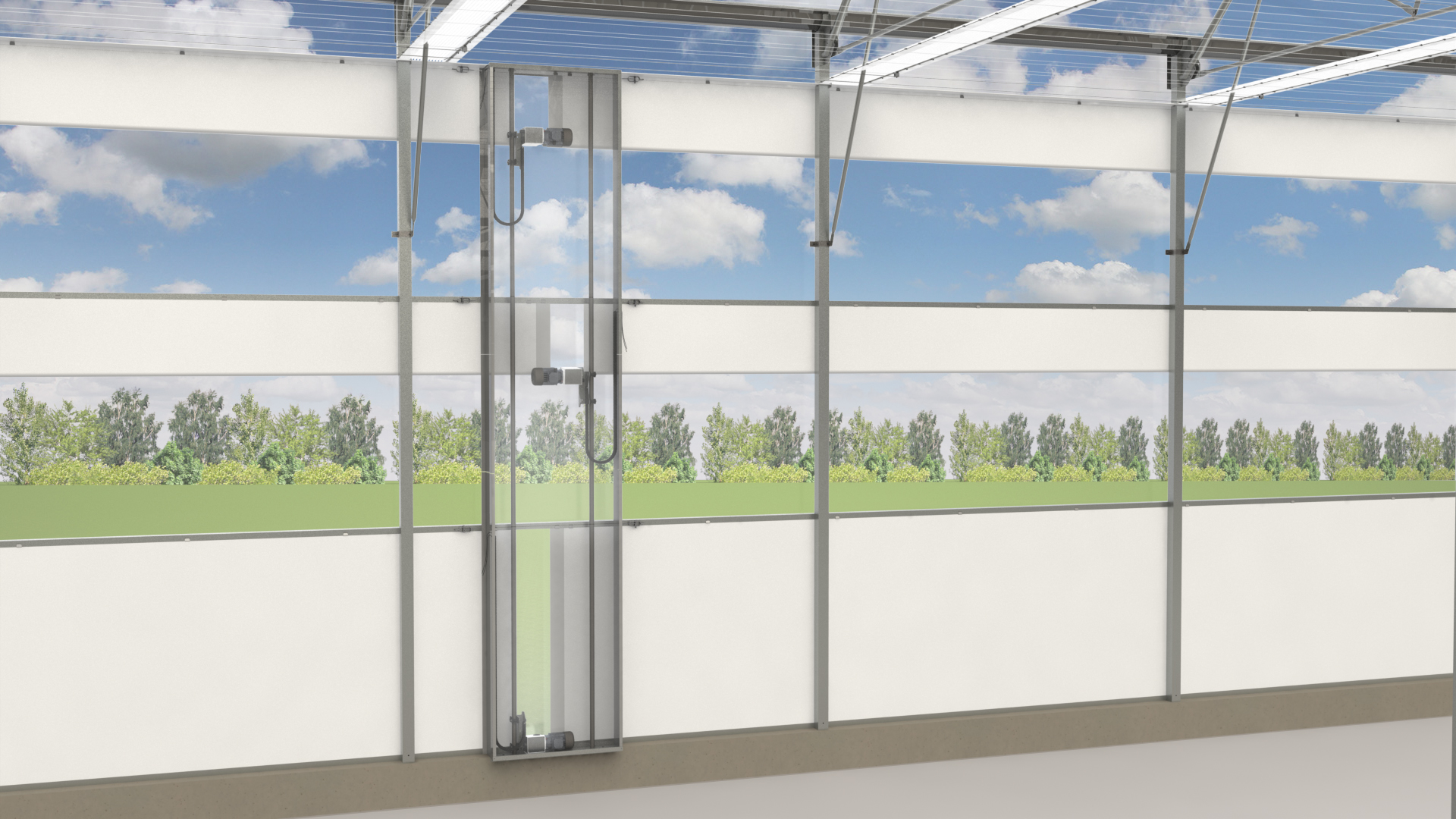

Drive systems for screening

Screen installations in poly greenhouses not only protect plants from harmful solar irradiation, they also have the ability to reduce sunlight and save energy by retaining heat. This way screens contribute to a large extent to achieving sustainability objectives. To make this possible, we offer a wide range of reliable drives developed specifically for this purpose.

Horizontal push-pull screening - THG40

We are happy to help you with making a calculation

Get in contact with usHorizontal screen systems are used in Venlo, wide-span and poly greenhouses. In the case of a push-pull screening system or gear rack screening system in a poly greenhouse, the screen is driven by THG gear racks in combination with a GWM or GW motor gearbox. The drive- and push-pull tubes are the connecting elements.

- Usable in nearly all greenhouse structures.

- Optimal dimensioning with the GWM or GW.

- Easy installation.

- Accurate.

- Highly reliable.

- Optional feedback to climate computer (GW).

GW motor gearbox

| Article | Description | T (50/60Hz) [Nm] | n (50/60Hz) [rpm] | L [mm] | D [mm] | P (50/60Hz) [kW] | I (@ Y) (50/60Hz) [A] | I (@ Δ) (50/60Hz) [A] | m [kg] |

| P.GW10.3.400.52.KW | GW10 5.2 3ph 400V with CW+CH 10B z16 | 100 / 80 | 5,2 / 6,2 | 191 | 124 | 0,18 / 0,22 | 0,7 / 0,7 | 1,2 / 1,2 | 24 |

2 P.GW10.3.400.52.KW 11 GW10 5.2 3ph 400V with CW+CH 10B z16 12 13 P.GW10.400.26.KW.jpg 14 15 CAT_P.GW10.400.26.KW_2D.gif 17 16 10 | |||||||||

| P.GW30.400.52.KW | GW30 5.2 3ph 400V with CW+CH 10B z16 | 300 / 240 | 5,2 / 6,2 | 220 | 145 | 0,37 / 0,44 | 1,2 / 1,2 | 2,1 / 2,1 | 27 |

2 P.GW30.400.52.KW 11 GW30 5.2 3ph 400V with CW+CH 10B z16 12 13 P.GW30.400.26.KW.jpg 14 15 CAT_P.GW30.400.26.KW_2D.gif 17 16 10 | |||||||||

| P.GW40.3.400.52.KW | GW40 5.2 3ph 400V with CW+CH 10B z16 | 400 / 320 | 5,2 / 6,2 | 220 | 137 | 0,55 / 0,66 | 1,5 / 1,5 | 2,6 / 2,6 | 29 |

2 P.GW40.3.400.52.KW 11 GW40 5.2 3ph 400V with CW+CH 10B z16 12 13 P.GW80.400.26.KW.jpg 14 15 CAT_P.GW80.400.26.KW_2D.gif 17 16 10 | |||||||||

| P.GW80.2.400.40.KW | GW80 4.0 3ph 400V with CW+CH 10B z16 d25 | 800 / 640 | 4,0 / 4,8 | 242 | 159 | 0,75 / 0,90 | 2,0 / 2,0 | 3,5 / 3,5 | 38 |

2 P.GW80.2.400.40.KW 11 GW80 4.0 3ph 400V with CW+CH 10B z16 d25 12 13 P.GW80.400.26.KW.jpg 14 15 CAT_P.GW80.400.26.KW_2D.gif 17 16 10 |

GWM motor gearbox

| Article | Description | T (50/60Hz) Nm | n (50/60Hz) [rpm] | i [-] | s [-] | P (50/60Hz) [kW] | I (@ Y) (50/60Hz) [A] | I (@ Δ) (50/60Hz) [A] | m [kg] |

| P.GWM45.1.400.26.KW | GWM45 2.6 3ph 400V with cw+ch 10B z16 | 450 / 360 | 2,6 / 3,1 | 505 | 0,75-42 | 0,37 / 0,44 | 1,0 / 1,2 | 1,7 / 2,1 | 17 |

2 P.GWM45.1.400.26.KW 11 GWM45 2.6 3ph 400V with cw+ch 10B z16 12 13 P.GWM30.1.400.26.KW.jpg 14 15 CAT_P.GWM30.1.400.26.KW_2D.gif 17 16 10 |

Mounting plate GW right angle

| Article | Description | H [mm] | A [mm] | m [kg] |

| P.MP.GW.H.A100 | Mounting plate GW right angle A100 H111 | 111 | 100 | 2,0 |

Mounting plate GWM straight

| Article | Description | A [mm] | L [mm] | m [kg] |

| P.MP.GWM.R.A163 | Mounting plate GWM straight A163 L204 | 163 | 204 | 0,9 |

Screen mounting plates

| Article | Description | A [mm] | B [mm] | H [mm] | m [kg] |

| P.SMP.GW.L290-475 | Screen mounting plate top screen L290-475 | 130 | 70 | 290 - 475 | 6,0 |

| P.SMP.GW.O | Screen mounting plate bottom screen | 130 | 70 | 210 | 2,7 |

| P.SMP.GW.L290-475.O | Screen mounting plate top+bottom | 130 | 70 | 290 - 475 | 8,7 |

Weld sprocket

| Article | Description | Chain | Shaft | Tmax [Nm] | Db [mm] | D [mm] | L [mm] | m [kg] |

| P.LKWL10B.Z16.D125 | Weld sprocket 10B z16 - 5/4" | 10B z16 | D125 | 420 | 43 | 96 | 30 | 0,4 |

2 P.LKWL10B.Z16.D125 11 Weld sprocket 10B z16 - 5/4" 12 13 P.LKWL10B.Z16.D125.jpg 15 16 CAT_P.LKWL10B.Z16.D125_2D.gif 17 10 |

Chain

| Article | Description | Tmax [Nm] | D [mm] | m [kg] |

| P.KTG10B-2.Z16 | Chain 10B z16 | 420 | 96 | 0,5 |

Sleeve sprocket

| Article | Description | Chain | Shaft | Tmax [Nm] | D2 [mm] | L [mm] | m [kg] |

| P.KWL10B.Z16.S20 | Sleeve sprocket 10B z16 p5/8" s20 | 10B z16 | S20 | 240 | 77 | 27 | 0,4 |

2 P.KWL10B.Z16.S20 11 Sleeve sprocket 10B z16 p5/8" s20 12 13 P.KWL10B.Z16.S20.jpg 14 15 CAT_P.KWL10B.Z16.S20_2D.gif 10 |

Tube bolt chain coupling

| Article | Description | Tmax [Nm] | D2 [mm] | D3 [mm] | L1 [mm] | L3 [mm] | m [kg] |

| P.BBKK10B.S20.D125 | Tube bolt CC set 10B S20 z16 5/4" | 420 | 43,1 | 96 | 30 | 150 | 1,9 |

2 P.BBKK10B.S20.D125 13 Tube bolt CC set 10B S20 z16 5/4" 17 18 P.BBKK10B.S20.D000.jpg 20 21 CAT_P.BBKK10B.D00.D125_2D.gif 10 |

Weld clearance joint

| Article | Description | Db [mm] | Type | m [kg] |

| P.THG40.SLV | THG40 weld clearance joint | 34,5/43,5 | S20 | 1,4 |

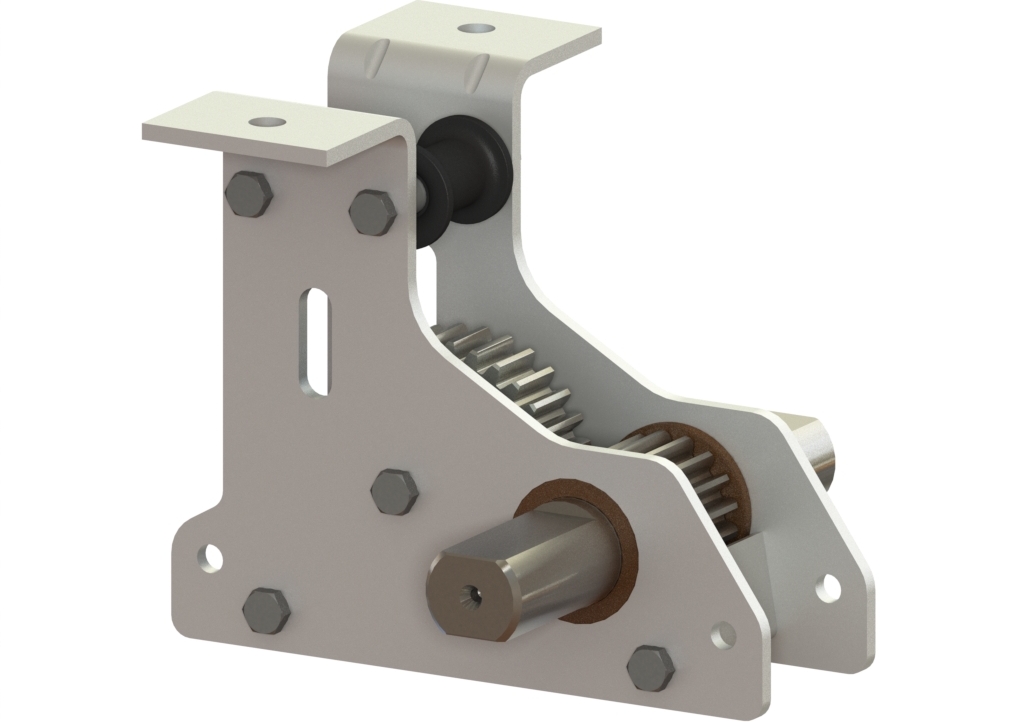

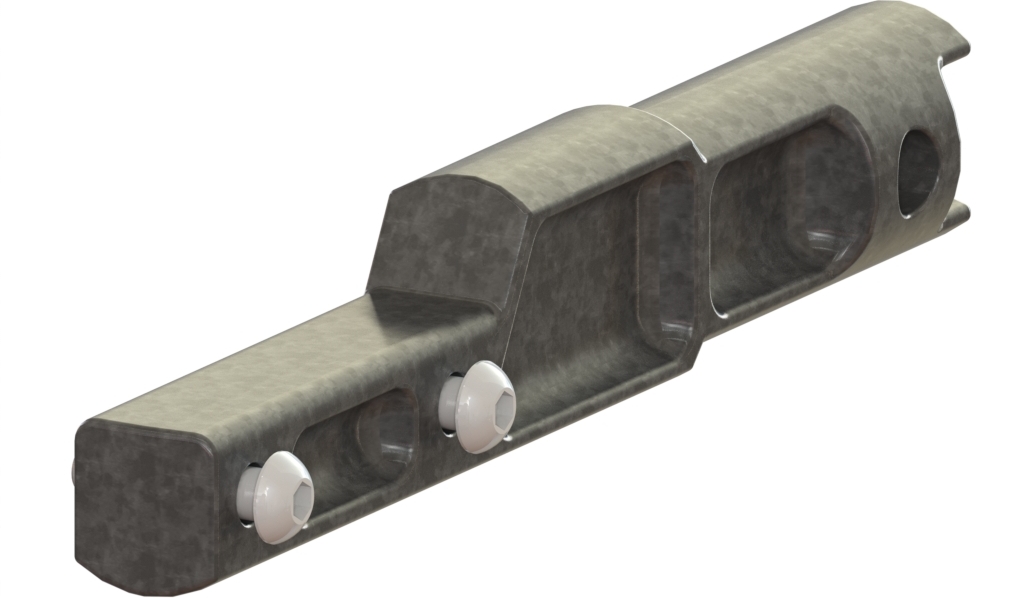

THG40-UNIT

| Article | Description | Tin [Nm] | i [-] | s [mm/rev] | m [kg] |

| P.THG40.UNIT | THG40 gearcase (1:1.8) | 5,71 | 1,82 | 75,8 | 2,15 |

| P.THG40.UNIT.K | THG40 gearcase (1:1.8) for clamp set | 5,71 | 1,82 | 75,8 | 2,15 |

THG40 counter ring

| Article | Description | m [kg] |

| P.THG40.CR.02 | THG40 counter ring for truss girder | 0,04 |

THG40 clamp set

| Article | Description | m [kg] |

| P.THG40.KBL.50 | THG40 clamping box set girder 50x30 | 0,18 |

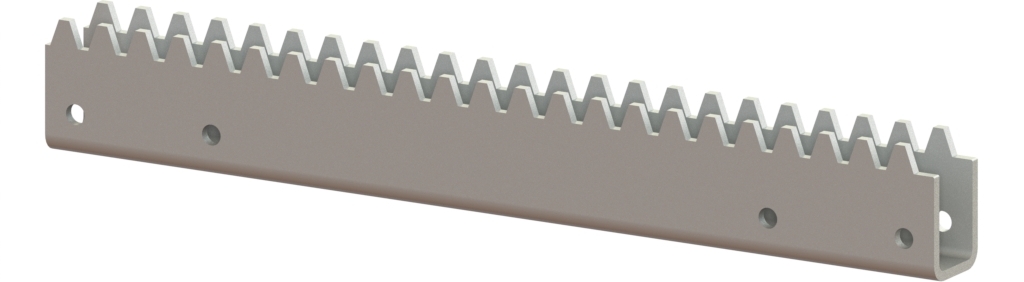

THG40 gear rack

| Article | Description | F [N] | L [mm] | m [kg] |

| P.THG40.L3613 | THG40 gear rack, section 3.0 m | 450 | 3613 | 7.3 |

| P.THG40.L3965 | THG40 gear rack, section 4.0 m | 450 | 3965 | 8,0 |

| P.THG40.L4467 | THG40 gear rack, section 4.5 m | 450 | 4467 | 9,0 |

| P.THG40.L4970 | THG40 gear rack, section 5.0 m | 450 | 4970 | 10,1 |

Coupling piece

| Article | Description | m [kg] |

| P.KS.D27 | THG40 coupling piece Ø27 + 2x clamping bush | 0,45 |

| P.KS.D32.02 | THG40 coupling piece Ø32 + 2x M6x25 | 0,41 |

Locking

Drive systems for screening

Screen installations in poly greenhouses not only protect plants from harmful solar irradiation, they also have the ability to reduce sunlight and save energy by retaining heat. This way screens contribute to a large extent to achieving sustainability objectives. To make this possible, we offer a wide range of reliable drives developed specifically for this purpose.

De Gier Drive Systems

+ 31 174 29 20 89