Pop hole doors central 1 winding shaft

We are happy to help you with making a calculation

Get in contact with us1" central winding shaft operates pop hole doors in free-range buildings. The centrally located GW motor gearbox is equipped with a tube bolt chain coupling on both sides. The GW motor gearbox, mounted on a mounting plate, drives the winding shaft and winds the cables around the shaft. Slide bearings support the shaft and ensure optimum guidance of the hatches.

- Minimum number of powerful GW motor gearboxes required.

- Compact construction, small footprint.

- Wide selection of 1-phase and 3-phase 50/60Hz motors.

- Complete package of couplings, bearing plates and components.

- UL/CSA for United States and Canadian market.

- Precise switching by integrated limit switch.

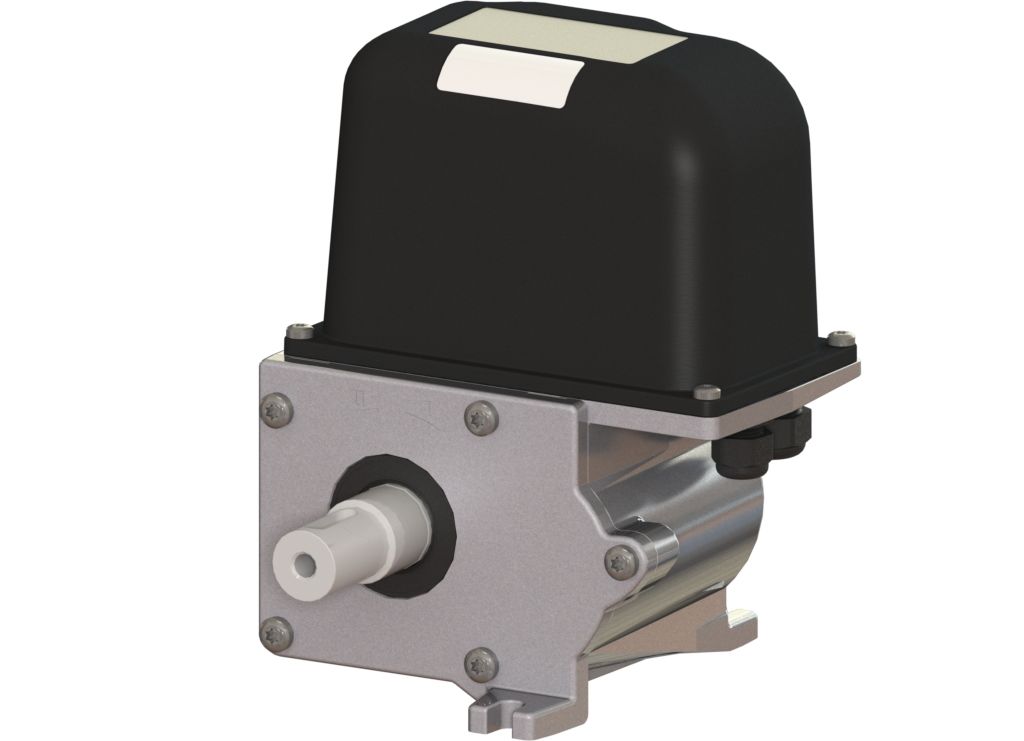

KL300 MultiWinch

| Article | Description | T [Nm] | n [rpm] | P [VA] | I [A] | s [rev] | m [kg] |

| P.KL300.1.024.08.L | KL300 0.8 24VDC for winch drum / sprocket | 90 | 0,8 (0,4) | 72 (48) | 3,0 (2,0) | 0,25 - 100 | 6,2 |

2 P.KL300.1.024.08.L 11 KL300 0.8 24VDC for winch drum / sprocket 12 13 P.KL300.1.024.08.L.jpg 14 15 CAT_P.KL300.1.024.08.L_2D.gif 10 |

Sprockets

| Article | Description | Chain | Shaft | Tmax [Nm] | D [mm] | L [mm] | m [kg] |

| P.KWL10B.Z16.D25 | Sleeve sprocket 10B z16 | 10B z16 | 420 | 25 | 96 | 40 | 0,6 |

2 P.KWL10B.Z16.D25 11 Sleeve sprocket 10B z16 12 13 P.KWL10B.Z16.D00.jpg 14 15 CAT_P.KWL10B.Z16.D00_2D.gif 10 |

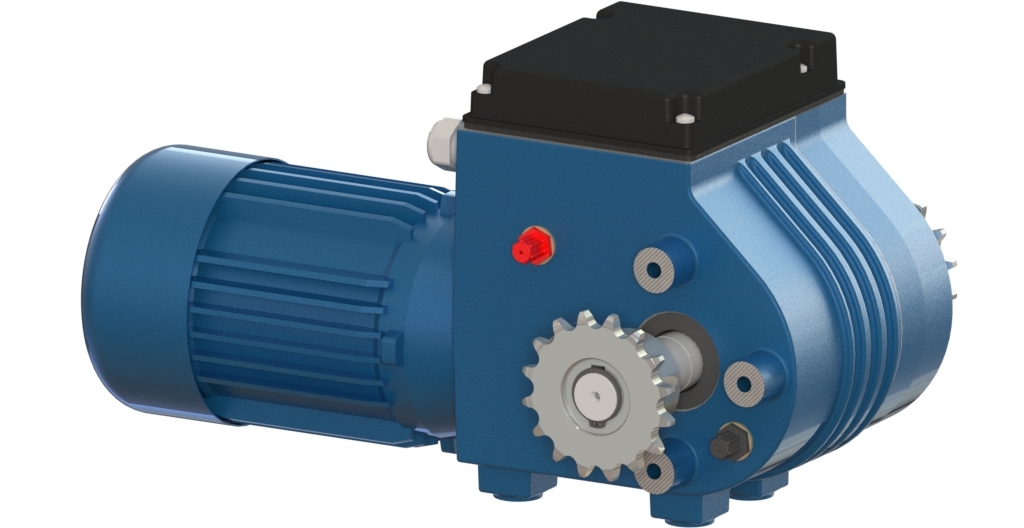

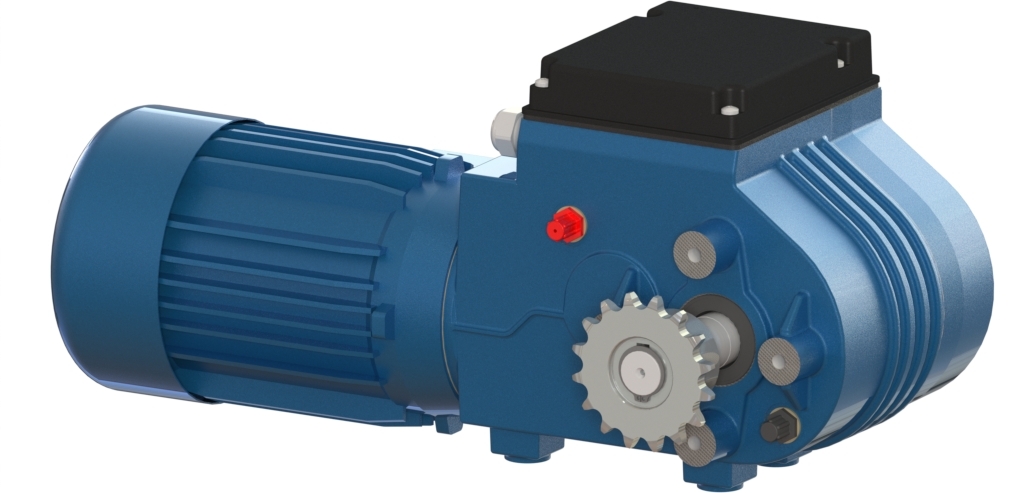

GW motor gearbox

| Article | Description | T (50/60Hz) [Nm] | n (50/60Hz) [rpm] | L [mm] | D [mm] | P (50/60Hz) [kW] | I (@ Y) (50/60Hz) [A] | I (@ Δ) (50/60Hz) [A] | m [kg] |

| P.GW10.3.230.26.KW | GW10 2.6 1ph 230V with CW+CH 10B z16 | 100 / - | 2,6 / - | 168 | 124 | 0,09 / - | 0,9 / - | - | 21 |

2 P.GW10.3.230.26.KW 11 GW10 2.6 1ph 230V with CW+CH 10B z16 12 13 P.GW10.400.26.KW.jpg 14 15 CAT_P.GW10.400.26.KW_2D.gif 17 16 10 | |||||||||

| P.GW10.3.400.26.KW | GW10 2.6 3ph 400V with CW+CH 10B z16 | 100 / 80 | 2,6 / 3,1 | 168 | 124 | 0,09 / 0,11 | 0,4 / 0,4 | 0,7 / 0,7 | 21 |

2 P.GW10.3.400.26.KW 11 GW10 2.6 3ph 400V with CW+CH 10B z16 12 13 P.GW10.400.26.KW.jpg 14 15 CAT_P.GW10.400.26.KW_2D.gif 17 16 10 | |||||||||

| P.GW30.2.230.26.KW | GW30 2.6 1ph 230V with CW+CH 10B z16 | 300 / - | 2,6 / - | 220 | 145 | 0,12 / - | 1,3 / - | - | 21 |

2 P.GW30.2.230.26.KW 11 GW30 2.6 1ph 230V with CW+CH 10B z16 12 13 P.GW30.400.26.KW.jpg 14 15 CAT_P.GW30.400.26.KW_2D.gif 17 16 10 | |||||||||

| P.GW30.400.26.KW | GW30 2.6 3ph 400V with CW+CH 10B z16 | 300 / 240 | 2,6 / 3,1 | 220 | 145 | 0,25 / 0,30 | 0,8 / 0,8 | 1,4 / 1,4 | 24 |

2 P.GW30.400.26.KW 11 GW30 2.6 3ph 400V with CW+CH 10B z16 12 13 P.GW30.400.26.KW.jpg 14 15 CAT_P.GW30.400.26.KW_2D.gif 17 16 10 | |||||||||

| P.GW40.2.230.26.KW | GW40 2.6 1ph 230V with CW+CH 10B z16 | 400 / - | 2,6 / - | 220 | 137 | 0,25 / - | 3,2 / - | - | 29 |

2 P.GW40.2.230.26.KW 11 GW40 2.6 1ph 230V with CW+CH 10B z16 12 13 P.GW80.400.26.KW.jpg 14 15 CAT_P.GW80.400.26.KW_2D.gif 17 16 10 | |||||||||

| P.GW40.400.26.KW | GW40 2.6 3ph 400V with CW+CH 10B z16 | 400 / 320 | 2,6 / 3,1 | 220 | 159 | 0,37 / 0,44 | 1,0 / 1,0 | 1,7 / 1,7 | 29 |

2 P.GW40.400.26.KW 11 GW40 2.6 3ph 400V with CW+CH 10B z16 12 13 P.GW80.400.26.KW.jpg 14 15 CAT_P.GW80.400.26.KW_2D.gif 17 16 10 |

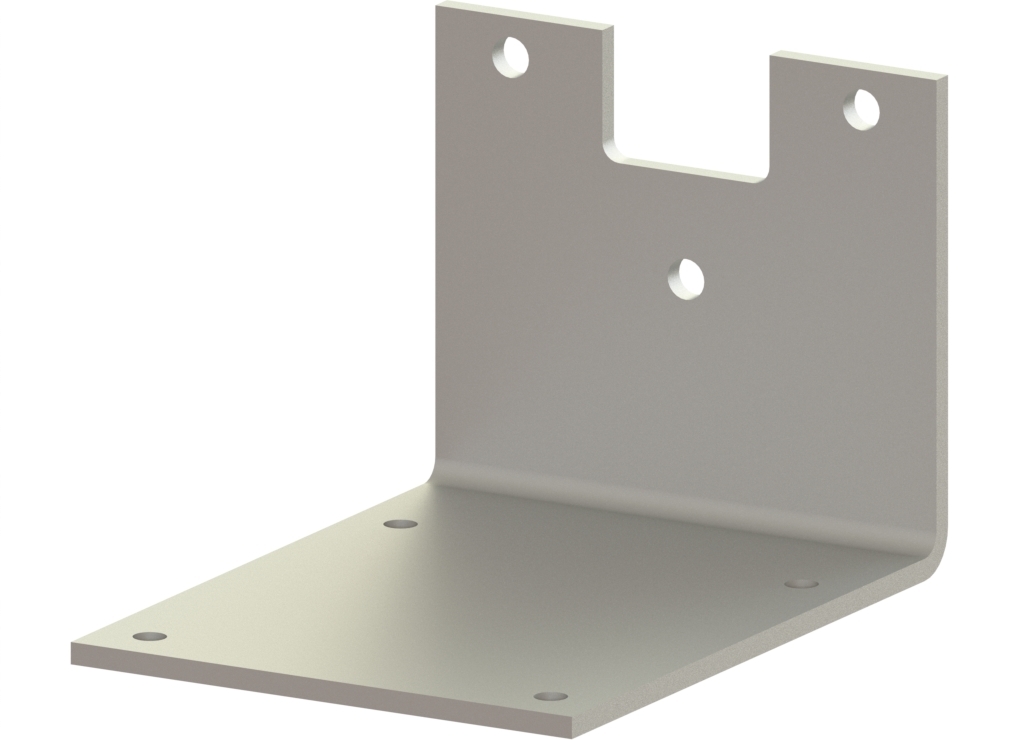

Mounting plate

| Article | Article name | A [mm] | H [mm] | m [kg] |

| P.MP.GW.H.A90 | Mounting plate GW right angle A90 H101 | 90 | 101 | 1,9 |

| P.MP.GW.H.A100 | Mounting plate GW right angle A100 H111 | 100 | 111 | 2,0 |

| P.MP.GW.H.A122 | Mounting plate GW right angle A122 H133 | 122 | 133 | 2,2 |

Tube bolt sprocket

| Article | Description | Chain | Shaft | Tmax [Nm] | Db [mm] | D [mm] | L [mm] | m [kg] |

| P.BBKWL10B.Z16.D100 | Tube bolt sprocket 10B z16 - 1" | 10B z16 | D100 | 420 | 34 | 96 | 150 | 0,8 |

2 P.BBKWL10B.Z16.D100 11 Tube bolt sprocket 10B z16 - 1" 12 13 P.BBKWL10B.Z16.D100.jpg 15 16 CAT_P.BBKWL10B.Z16.D100_2D.gif 17 10 |

Weld sprocket

| Article | Description | Chain | Shaft | Tmax [Nm] | Db [mm] | D [mm] | L [mm] | m [kg] |

| P.LKWL10B.Z16.D100 | Weld sprocket 10B z16 - 1" and 2" | 10B z16 | D100 | 420 | 34 | 96 | 30 | 0,5 |

2 P.LKWL10B.Z16.D100 11 Weld sprocket 10B z16 - 1" and 2" 12 13 P.LKWL10B.Z16.D100.jpg 15 16 CAT_P.LKWL10B.Z16.D100_2D.gif 17 10 |

Slide bearing plate

| Article | Description | A [mm] | H [mm] | L [mm] | m [kg] |

| P.GL100.H.L150 | Slide bearing plate 1" H A92 L150 mm | 92 | 125 | 150 | 0,2 |

| P.GL100.H.L158 | Slide bearing plate 1" H A100 L158 mm | 100 | 133 | 158 | 0,2 |

| P.GL100.H.L180 | Slide bearing plate 1" H A122 L180 mm | 122 | 155 | 180 | 0,2 |

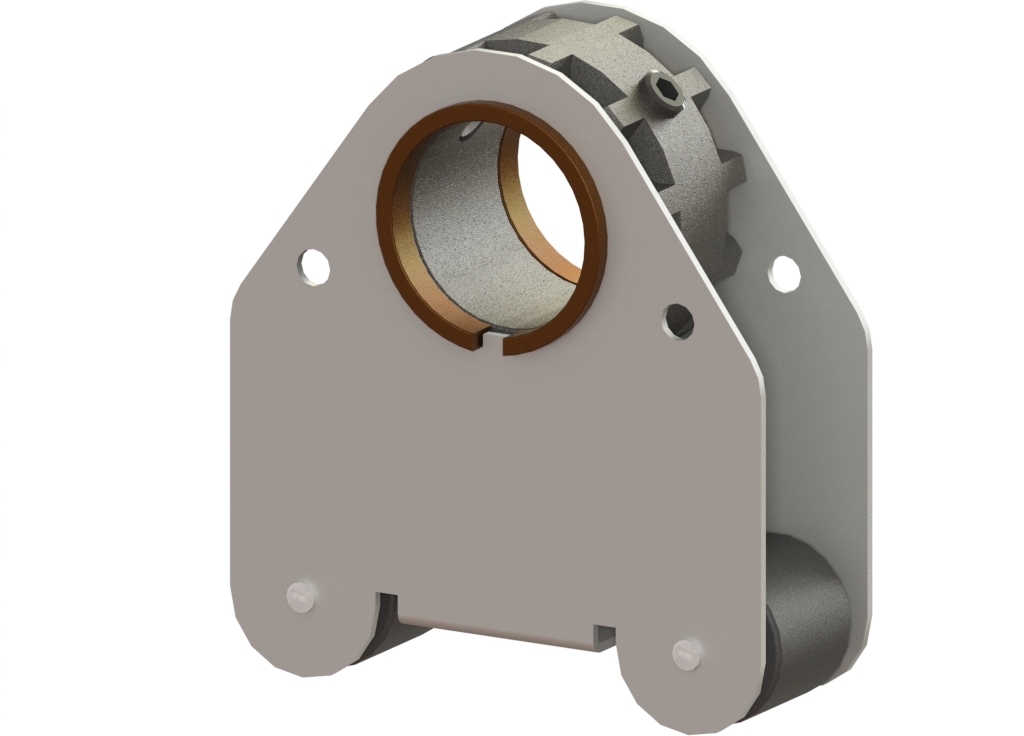

Ball bearing plates

| Article | Description | A [mm] | H [mm] | D1 [mm] | d [mm] | m [kg] |

| P.KL100.H.A089 | Ball bearing plate 1" H A89 H135 | 89 | 135 | 34,5 | 3 | 0,6 |

2 P.KL100.H.A089 11 Ball bearing plate 1" H A89 H135 12 13 P.KL000.H.A000.jpg 14 10 CAT_P.KL000.H.A000_2D.gif | ||||||

| P.KL100.H.A122 | Ball bearing plate 1" H A122 H168 | 122 | 168 | 34,5 | 3 | 0,7 |

2 P.KL100.H.A122 11 Ball bearing plate 1" H A122 H168 12 13 P.KL000.H.A000.jpg 14 10 CAT_P.KL000.H.A000_2D.gif |

Cable ring

| Article | Description | D1 [mm] | D2 [mm] | m [kg] |

| P.KABELRING | Cable clamp 1" d36 D50 4xØ4,5 | 50 | 36 | 0,09 |

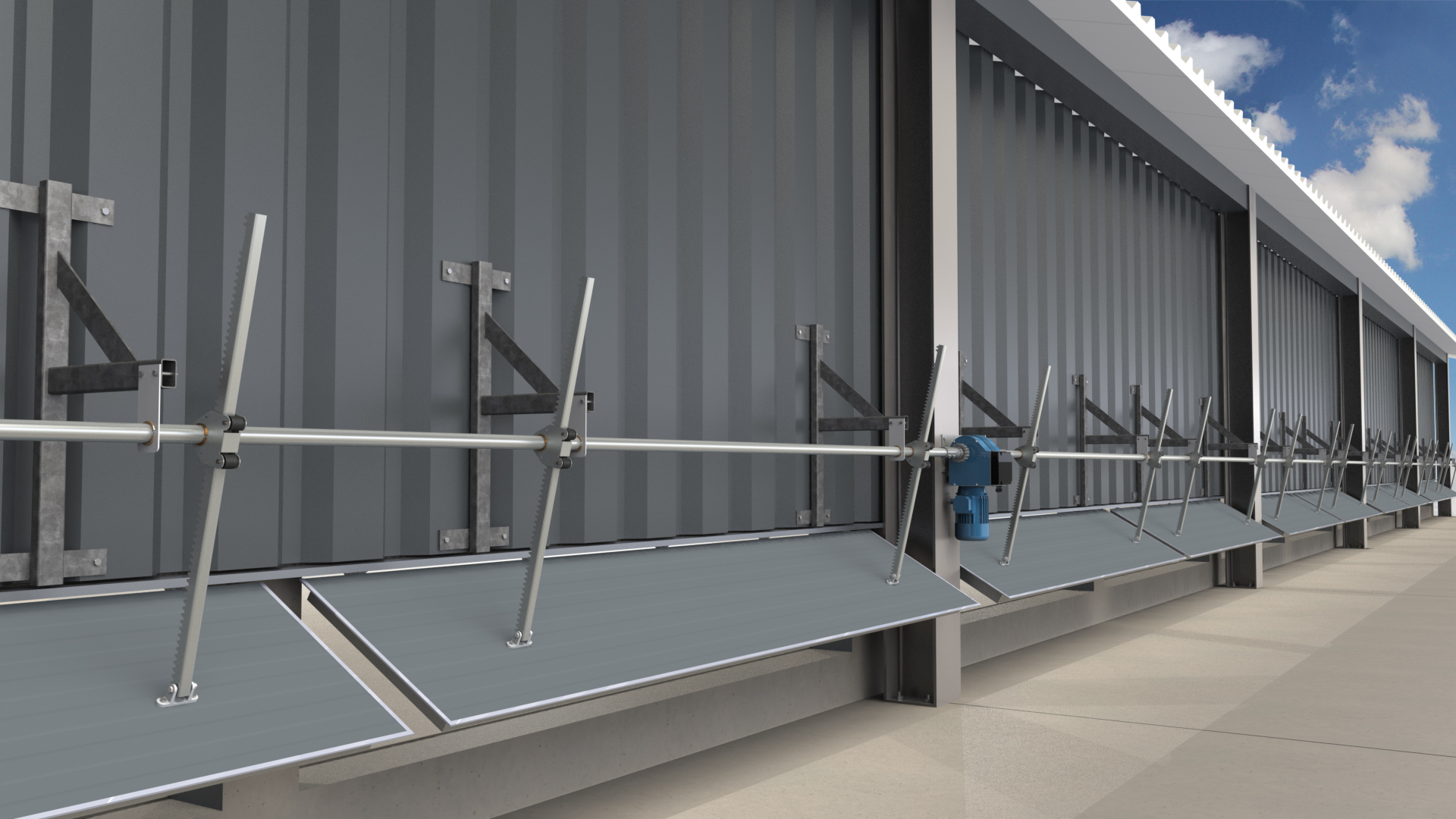

Drive systems for pop hole doors

Pop-hole doors are essential to provide space and well-being for poultry. They also contribute to keeping the climate in the building optimal. Our powerful GW drives offer the perfect solution for this purpose. The combination of these drives with drums or TGA racks can open several pop hole doors at the same time. This keeps the number of drives in the building to a minimum.

Pop hole doors with gear racks (inside)

We are happy to help you with making a calculation

Get in contact with usThe centrally located GW motor gearbox is equipped with a tube bolt chain coupling on both sides. The GW motor gearbox drives the 1" drive shaft, which is equipped with THG30 gear rack systems. The sliding doors are operated by converting the rotary motion of the shaft into linear motion. Slide bearings support the shaft and ensure optimum guidance of the doors.

- Powerful motor gearboxes, maximum operation of pop-out doors.

- Compact construction, small installation space.

- Wide selection of 1-phase and 3-phase 50/60Hz motors.

- Complete package of couplings, bearing plates and components.

- UL/CSA for United States and Canadian market.

- Sturdy guidance by THG30 gear rack system.

KL300 MultiWinch

| Article | Description | T [Nm] | n [rpm] | P [VA] | I [A] | s [rev] | m [kg] |

| P.KL300.1.024.08.L | KL300 0.8 24VDC for winch drum / sprocket | 90 | 0,8 (0,4) | 72 (48) | 3,0 (2,0) | 0,25 - 100 | 6,2 |

2 P.KL300.1.024.08.L 11 KL300 0.8 24VDC for winch drum / sprocket 12 13 P.KL300.1.024.08.L.jpg 14 15 CAT_P.KL300.1.024.08.L_2D.gif 10 |

Sprockets

| Article | Description | Chain | Shaft | Tmax [Nm] | D [mm] | L [mm] | m [kg] |

| P.KWL10B.Z16.D25 | Sleeve sprocket 10B z16 | 10B z16 | 420 | 25 | 96 | 40 | 0,6 |

2 P.KWL10B.Z16.D25 11 Sleeve sprocket 10B z16 12 13 P.KWL10B.Z16.D00.jpg 14 15 CAT_P.KWL10B.Z16.D00_2D.gif 10 |

GW motor gearbox

| Article | Description | T (50/60Hz) [Nm] | n (50/60Hz) [rpm] | L [mm] | D [mm] | P (50/60Hz) [kW] | I (@ Y) (50/60Hz) [A] | I (@ Δ) (50/60Hz) [A] | m [kg] |

| P.GW10.3.230.26.KW | GW10 2.6 1ph 230V with CW+CH 10B z16 | 100 / - | 2,6 / - | 168 | 124 | 0,09 / - | 0,9 / - | - | 21 |

2 P.GW10.3.230.26.KW 11 GW10 2.6 1ph 230V with CW+CH 10B z16 12 13 P.GW10.400.26.KW.jpg 14 15 CAT_P.GW10.400.26.KW_2D.gif 17 16 10 | |||||||||

| P.GW10.3.400.26.KW | GW10 2.6 3ph 400V with CW+CH 10B z16 | 100 / 80 | 2,6 / 3,1 | 168 | 124 | 0,09 / 0,11 | 0,4 / 0,4 | 0,7 / 0,7 | 21 |

2 P.GW10.3.400.26.KW 11 GW10 2.6 3ph 400V with CW+CH 10B z16 12 13 P.GW10.400.26.KW.jpg 14 15 CAT_P.GW10.400.26.KW_2D.gif 17 16 10 | |||||||||

| P.GW30.2.230.26.KW | GW30 2.6 1ph 230V with CW+CH 10B z16 | 300 / - | 2,6 / - | 220 | 145 | 0,12 / - | 1,3 / - | - | 21 |

2 P.GW30.2.230.26.KW 11 GW30 2.6 1ph 230V with CW+CH 10B z16 12 13 P.GW30.400.26.KW.jpg 14 15 CAT_P.GW30.400.26.KW_2D.gif 17 16 10 | |||||||||

| P.GW30.400.26.KW | GW30 2.6 3ph 400V with CW+CH 10B z16 | 300 / 240 | 2,6 / 3,1 | 220 | 145 | 0,25 / 0,30 | 0,8 / 0,8 | 1,4 / 1,4 | 24 |

2 P.GW30.400.26.KW 11 GW30 2.6 3ph 400V with CW+CH 10B z16 12 13 P.GW30.400.26.KW.jpg 14 15 CAT_P.GW30.400.26.KW_2D.gif 17 16 10 | |||||||||

| P.GW40.2.230.26.KW | GW40 2.6 1ph 230V with CW+CH 10B z16 | 400 / - | 2,6 / - | 220 | 137 | 0,25 / - | 3,2 / - | - | 29 |

2 P.GW40.2.230.26.KW 11 GW40 2.6 1ph 230V with CW+CH 10B z16 12 13 P.GW80.400.26.KW.jpg 14 15 CAT_P.GW80.400.26.KW_2D.gif 17 16 10 | |||||||||

| P.GW40.400.26.KW | GW40 2.6 3ph 400V with CW+CH 10B z16 | 400 / 320 | 2,6 / 3,1 | 220 | 159 | 0,37 / 0,44 | 1,0 / 1,0 | 1,7 / 1,7 | 29 |

2 P.GW40.400.26.KW 11 GW40 2.6 3ph 400V with CW+CH 10B z16 12 13 P.GW80.400.26.KW.jpg 14 15 CAT_P.GW80.400.26.KW_2D.gif 17 16 10 |

Mounting plate

| Article | Article name | A [mm] | H [mm] | m [kg] |

| P.MP.GW.H.A90 | Mounting plate GW right angle A90 H101 | 90 | 101 | 1,9 |

| P.MP.GW.H.A100 | Mounting plate GW right angle A100 H111 | 100 | 111 | 2,0 |

| P.MP.GW.H.A122 | Mounting plate GW right angle A122 H133 | 122 | 133 | 2,2 |

Tube bolt sprocket

| Article | Description | Chain | Shaft | Tmax [Nm] | Db [mm] | D [mm] | L [mm] | m [kg] |

| P.BBKWL10B.Z16.D100 | Tube bolt sprocket 10B z16 - 1" | 10B z16 | D100 | 420 | 34 | 96 | 150 | 0,8 |

2 P.BBKWL10B.Z16.D100 11 Tube bolt sprocket 10B z16 - 1" 12 13 P.BBKWL10B.Z16.D100.jpg 15 16 CAT_P.BBKWL10B.Z16.D100_2D.gif 17 10 |

Weld procket

| Article | Description | Chain | Shaft | Tmax [Nm] | Db [mm] | D [mm] | L [mm] | m [kg] |

| P.LKWL10B.Z16.D100 | Weld sprocket 10B z16 - 1" and 2" | 10B z16 | D100 | 420 | 34 | 96 | 30 | 0,5 |

2 P.LKWL10B.Z16.D100 11 Weld sprocket 10B z16 - 1" and 2" 12 13 P.LKWL10B.Z16.D100.jpg 15 16 CAT_P.LKWL10B.Z16.D100_2D.gif 17 10 |

Ball bearing plates

| Article | Description | A [mm] | H [mm] | D1 [mm] | d [mm] | m [kg] |

| P.KL100.H.A089 | Ball bearing plate 1" H A89 H135 | 89 | 135 | 34,5 | 3 | 0,6 |

2 P.KL100.H.A089 11 Ball bearing plate 1" H A89 H135 12 13 P.KL000.H.A000.jpg 14 10 CAT_P.KL000.H.A000_2D.gif | ||||||

| P.KL100.H.A122 | Ball bearing plate 1" H A122 H168 | 122 | 168 | 34,5 | 3 | 0,7 |

2 P.KL100.H.A122 11 Ball bearing plate 1" H A122 H168 12 13 P.KL000.H.A000.jpg 14 10 CAT_P.KL000.H.A000_2D.gif |

THG30 gearcase

| Article | Description | T [Nm] | s [mm/rev] | Usage | m [kg] |

| P.THG30.UNIT.U | THG30 Universal | 10,4 | 138,23 | Intens | 0,43 |

THG30 rack

| Article | Description | F [N] | L [mm] | D [mm] | B [mm] | m [kg] |

| P.THG30.3.L797 | THG30 rack 3 mm L=797 mm | 450 | 797 | 25 | 3 | 1,2 |

2 P.THG30.3.L797 11 THG30 rack 3 mm L=797 mm 12 13 RAW_P.THG30.0.L0000.jpg 14 10 CAT_P.THG30.3.L0000_2D.gif | ||||||

| P.THG30.3.L998 | THG30 rack 3 mm L=998 mm | 450 | 998 | 25 | 3 | 1,5 |

2 P.THG30.3.L998 11 THG30 rack 3 mm L=998 mm 12 13 RAW_P.THG30.0.L0000.jpg 14 10 CAT_P.THG30.3.L0000_2D.gif | ||||||

| P.THG30.3.L1099 | THG30 rack 3 mm L=1099 mm | 450 | 1099 | 25 | 3 | 1,7 |

2 P.THG30.3.L1099 11 THG30 rack 3 mm L=1099 mm 12 13 RAW_P.THG30.0.L0000.jpg 14 10 CAT_P.THG30.3.L0000_2D.gif | ||||||

| P.THG30.3.L1300 | THG30 rack 3 mm L=1300 mm | 450 | 1300 | 25 | 3 | 2,0 |

2 P.THG30.3.L1300 11 THG30 rack 3 mm L=1300 mm 12 13 RAW_P.THG30.0.L0000.jpg 14 10 CAT_P.THG30.3.L0000_2D.gif | ||||||

| P.THG30.3.L1400 | THG30 rack 3 mm L=1400 mm | 450 | 1400 | 25 | 3 | 2,2 |

2 P.THG30.3.L1400 11 THG30 rack 3 mm L=1400 mm 12 13 RAW_P.THG30.0.L0000.jpg 14 10 CAT_P.THG30.3.L0000_2D.gif | ||||||

| P.THG30.3.L1500 | THG30 rack 3 mm L=1500 mm | 450 | 1500 | 25 | 3 | 2,2 |

2 P.THG30.3.L1500 11 THG30 rack 3 mm L=1500 mm 12 13 RAW_P.THG30.0.L0000.jpg 14 10 CAT_P.THG30.3.L0000_2D.gif |

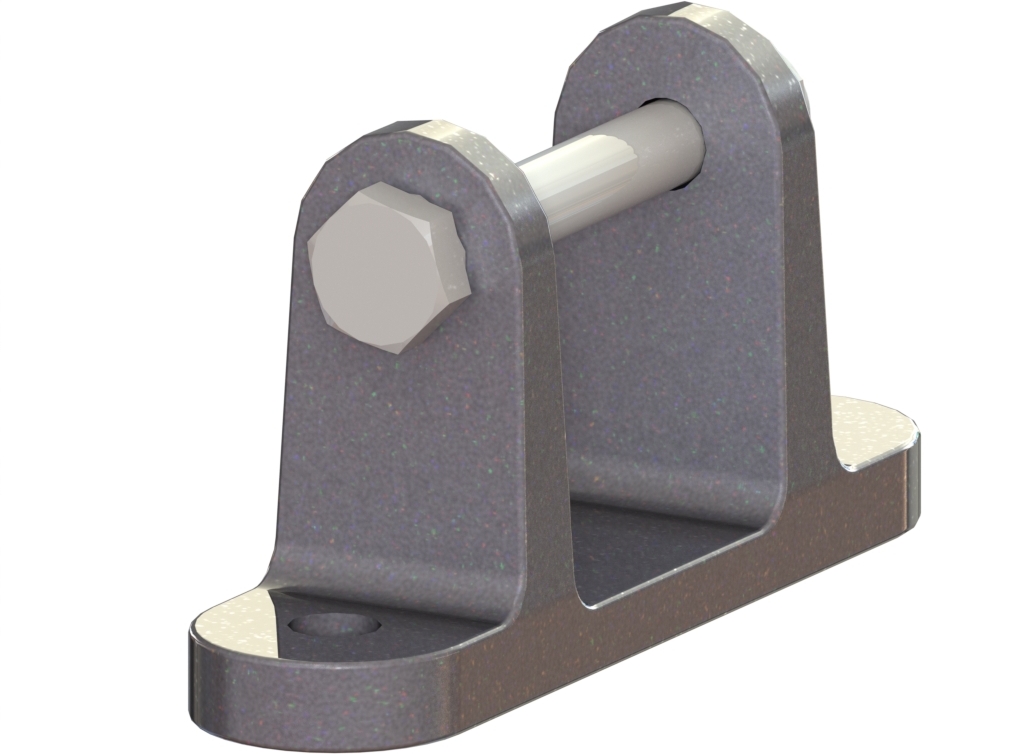

THG30 window bracket

| Article | Article name | m [kg] |

| P.THG30.RB | THG30 aluminium window bracket | 0,06 |

Slide bearing plate

| Article | Description | A [mm] | H [mm] | L [mm] | m [kg] |

| P.GL100.H.L150 | Slide bearing plate 1" H A92 L150 mm | 92 | 125 | 150 | 0,2 |

| P.GL100.H.L158 | Slide bearing plate 1" H A100 L158 mm | 100 | 133 | 158 | 0,2 |

| P.GL100.H.L180 | Slide bearing plate 1" H A122 L180 mm | 122 | 155 | 180 | 0,2 |

Drive systems for pop hole doors

Pop-hole doors are essential to provide space and well-being for poultry. They also contribute to keeping the climate in the building optimal. Our powerful GW drives offer the perfect solution for this purpose. The combination of these drives with drums or TGA racks can open several pop hole doors at the same time. This keeps the number of drives in the building to a minimum.

De Gier Drive Systems

+ 31 174 29 20 89