Dispenser central winding shaft

We are happy to help you with making a calculation

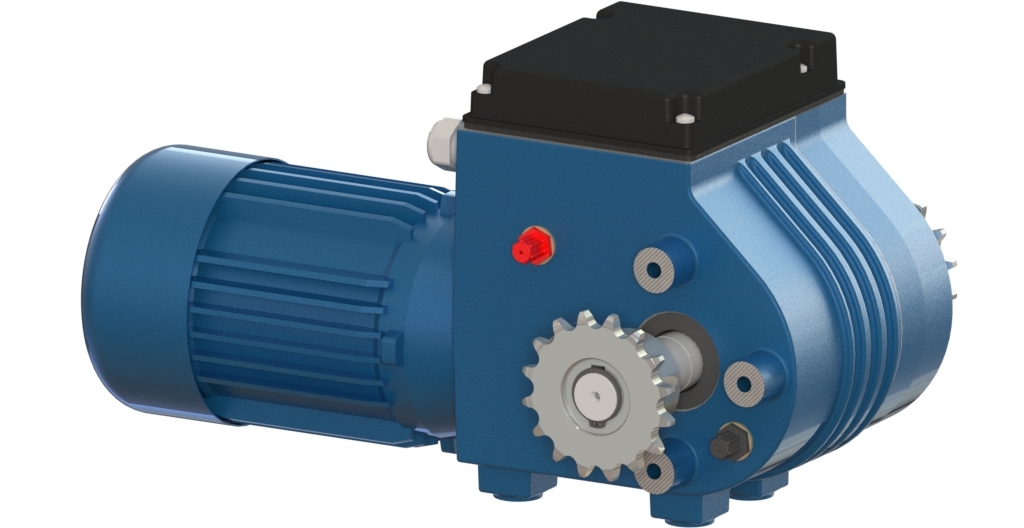

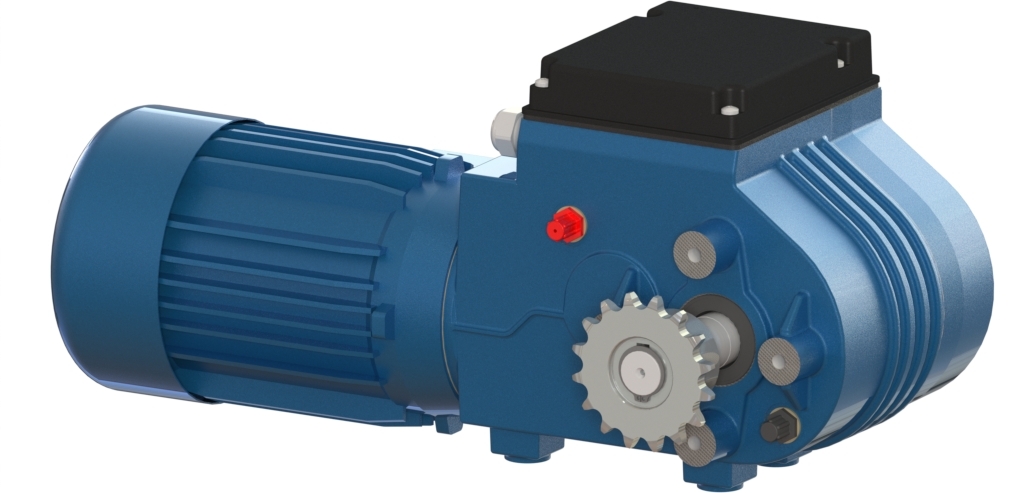

Get in contact with usA 1" and 5/4" winding shaft is mounted along the wall of the building. A centrally located GW motor gearbox is fitted with a tube bolt chain coupling on both sides. The GW motor gearbox, mounted on a mounting plate, drives the winding shaft and winds the cables around the shaft. These open the dispensers in a controlled manner. Slide bearings or ball bearings support the shaft.

- Powerful drives for a maximum number of dispenser motions.

- Highly reliable direct drive.

- Low-noise, low-speed motors.

- Complete package for flexible solutions.

- UL/CSA for United States and Canadian market.

- Precise switching by integrated limit switch.

GW motor gearbox

| Article | Description | T (50/60Hz) [Nm] | L [mm] | D [mm] | P (50/60Hz) [kW] | I (@ Δ) (50/60Hz) [A] | I (@ Y) (50/60Hz) [A] | m [kg] |

| P.GW10.3.230.26.KW | GW10 2.6 1ph 230V with CW+CH 10B z16 | 100 / - | 168 | 124 | 0,09 / - | - | 0,9 / - | 21 |

2 P.GW10.3.230.26.KW 11 GW10 2.6 1ph 230V with CW+CH 10B z16 13 14 P.GW10.400.26.KW.jpg 15 16 CAT_P.GW10.400.26.KW_2D.gif 17 10 | ||||||||

| P.GW10.3.400.26.KW | GW10 2.6 3ph 400V with CW+CH 10B z16 | 100 / 80 | 168 | 124 | 0,09 / 0,11 | 0,7 / 0,7 | 0,4 / 0,4 | 21 |

2 P.GW10.3.400.26.KW 11 GW10 2.6 3ph 400V with CW+CH 10B z16 13 14 P.GW10.400.26.KW.jpg 15 16 CAT_P.GW10.400.26.KW_2D.gif 17 10 | ||||||||

| P.GW30.2.230.26.KW | GW30 2.6 1ph 230V with CW+CH 10B z16 | 300 / - | 220 | 145 | 0,12 / - | - | 1,3 / - | 21 |

2 P.GW30.2.230.26.KW 11 GW30 2.6 1ph 230V with CW+CH 10B z16 13 14 P.GW30.400.26.KW.jpg 15 16 CAT_P.GW30.400.26.KW_2D.gif 17 10 | ||||||||

| P.GW30.400.26.KW | GW30 2.6 3ph 400V with CW+CH 10B z16 | 300 / 240 | 220 | 145 | 0,25 / 0,30 | 1,4 / 1,4 | 0,8 / 0,8 | 24 |

2 P.GW30.400.26.KW 11 GW30 2.6 3ph 400V with CW+CH 10B z16 13 14 P.GW30.400.26.KW.jpg 15 16 CAT_P.GW30.400.26.KW_2D.gif 17 10 | ||||||||

| P.GW40.2.230.26.KW | GW40 2.6 1ph 230V with CW+CH 10B z16 | 400 / - | 220 | 137 | 0,25 / - | - | 3,2 / - | 29 |

2 P.GW40.2.230.26.KW 11 GW40 2.6 1ph 230V with CW+CH 10B z16 13 14 P.GW80.400.26.KW.jpg 15 16 CAT_P.GW80.400.26.KW_2D.gif 17 10 | ||||||||

| P.GW40.400.26.KW | GW40 2.6 3ph 400V with CW+CH 10B z16 | 400 / 320 | 220 | 159 | 0,37 / 0,44 | 1,7 / 1,7 | 1,0 / 1,0 | 29 |

2 P.GW40.400.26.KW 11 GW40 2.6 3ph 400V with CW+CH 10B z16 13 14 P.GW80.400.26.KW.jpg 15 16 CAT_P.GW80.400.26.KW_2D.gif 17 10 |

Mounting plate

| Article | Description | A [mm] | H [mm] | m [kg] |

| P.MP.GW.H.A90 | Mounting plate GW right angle A90 H101 | 90 | 101 | 1,9 |

| P.MP.GW.H.A122 | Mounting plate GW right angle A122 H133 | 122 | 133 | 2,2 |

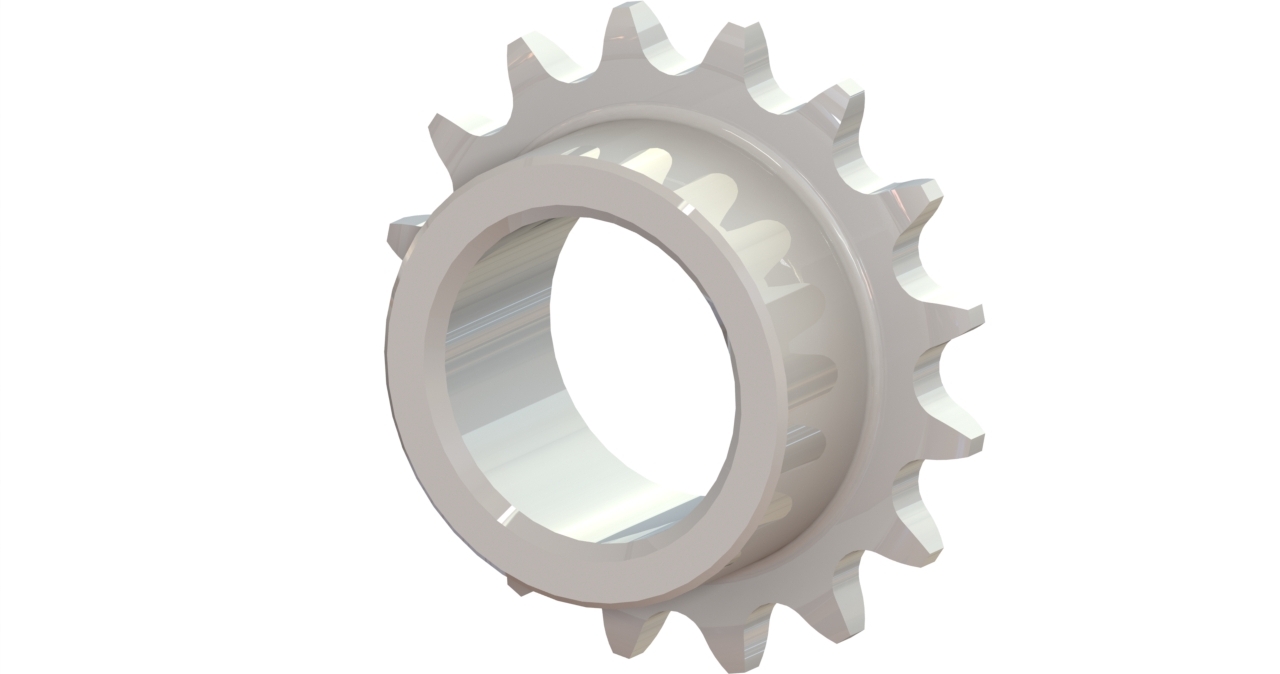

Tube bolt sprocket

| Article | Description | Chain | Shaft | Tmax [Nm] | Db [mm] | D [mm] | L [mm] | m [kg] |

| P.BBKWL10B.Z16.D100 | Tube bolt sprocket 10B z16 - 1" | 10B z16 | D100 | 420 | 34 | 96 | 150 | 0,8 |

2 P.BBKWL10B.Z16.D100 11 Tube bolt sprocket 10B z16 - 1" 12 13 P.BBKWL10B.Z16.D100.jpg 15 16 CAT_P.BBKWL10B.Z16.D100_2D.gif 17 10 | ||||||||

| P.BBKWL10B.Z16.D125 | Tube bolt sprocket 10B z16 - 5/4" | 10B z16 | D125 | 420 | 43 | 96 | 145 | 0,7 |

2 P.BBKWL10B.Z16.D125 11 Tube bolt sprocket 10B z16 - 5/4" 12 13 P.BBKWL10B.Z16.D125.jpg 15 16 CAT_P.BBKWL10B.Z16.D125_2D.gif 17 10 |

Weld sprocket

| Article | Description | Chain | Shaft | Tmax [Nm] | Db [mm] | D [mm] | L [mm] | m [kg] |

| P.LKWL10B.Z16.D100 | Weld sprocket 10B z16 - 1" and 2" | 10B z16 | D100 | 420 | 34 | 96 | 30 | 0,5 |

2 P.LKWL10B.Z16.D100 11 Weld sprocket 10B z16 - 1" and 2" 12 13 P.LKWL10B.Z16.D100.jpg 15 16 CAT_P.LKWL10B.Z16.D100_2D.gif 17 10 | ||||||||

| P.LKWL10B.Z16.D125 | Weld sprocket 10B z16 - 5/4" | 10B z16 | D125 | 420 | 43 | 96 | 30 | 0,4 |

2 P.LKWL10B.Z16.D125 11 Weld sprocket 10B z16 - 5/4" 12 13 P.LKWL10B.Z16.D125.jpg 15 16 CAT_P.LKWL10B.Z16.D125_2D.gif 17 10 |

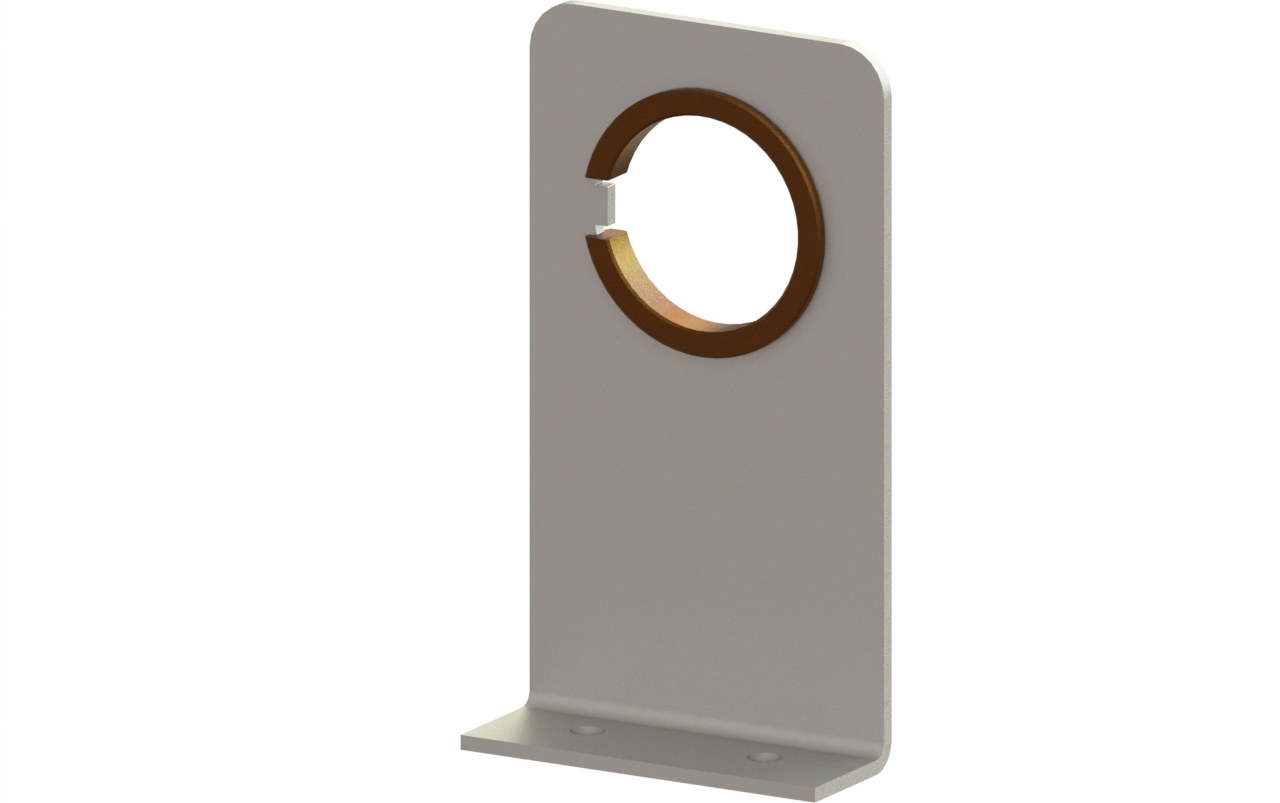

Ball bearing plate

| Article | Description | A [mm] | L [mm] | m [kg] |

| P.KL100.H.A089 | Ball bearing plate 1" H A89 H135 | 89 | 135 | 0,6 |

| P.KL100.H.A122 | Ball bearing plate 1" H A122 H168 | 122 | 168 | 0,7 |

| P.KL125.H.A89 | Ball bearing plate 5/4" H A89 H135 | 89 | 135 | 0,6 |

| P.KL125.H.A122 | Ball bearing plate 5/4" H A122 H168 | 122 | 168 | 0,7 |

Slide bearing plate

| Article | Description | A [mm] | H [mm] | L [mm] | m [kg] |

| P.GL100.H.L150 | Slide bearing plate 1" H A92 L150 mm | 92 | 125 | 150 | 0,2 |

| P.GL100.H.L180 | Slide bearing plate 1" H A122 L180 mm | 122 | 155 | 180 | 0,2 |

| P.GL125.H.L155 | Slide bearing plate 5/4" H A90 L155 mm | 90 | 130 | 155 | 0,3 |

| P.GL125.H.L186 | Slide bearing plate 5/4" H A122 L186 mm | 122 | 162 | 186 | 0,3 |

Cable ring

| Article | Description | D1 [mm] | D2 [mm] | m [kg] |

| P.KABELRING.D125 | Cable clamp 1-1/4" d44 D60 4xØ4,5 | 60 | 44 | 0,11 |

| P.KABELRING | Cable clamp 1" d36 D50 4xØ4,5 | 50 | 36 | 0,09 |

Drive systems for dispensers

Good feed consumption under minimal stress leads to the best growth. If pigs are not offered feed at the same time, unrest occurs in the building and they may become stressed. It is therefore important that dispensers are opened in a controlled manner so that livestock are offered feed at the same time in order to prevent stress. With our powerful GW series, we offer unique solutions for optimal feed distribution.

De Gier Drive Systems

+ 31 174 29 20 89